This past January, I had postulated that 2017 would be the “Year of the Embedded FPGA”, as a compelling IP offering for many SoC designs (link). As the year draws to a close, I thought it would be interesting to see how that prediction turned out.

The criteria that would be appropriate metrics include: increasing capital investment; increasing customer adoption; support for a diverse set of applications; and, an emerging set of standard product offerings to accelerate adoption. To be sure, qualified test vehicles fabricated on multiple foundry process nodes are also crucial, as is a solid methodology flow for design synthesis and physical personalization.

If you have been following eFPGA technology, you have no doubt seen recent press releases highlight the growing investment and the customer endorsements. In addition, previous Semiwiki articles have described how eFPGA features are addressing both high-performance and low-power requirements, as well as the ease with which the IP block is connected to the pervasive AMBA bus protocols (link, link). So far, the prediction is looking pretty good. 🙂

The last metric – the introduction of standard product offerings – has received less attention, perhaps. To gain a better understanding of the eFPGA product strategy, I recently met up with Aparna Ranachandran, Tony Kozaczuk, and Cheng Wang at Flex Logix. I asked how their technology offerings are evolving, as the customer interest grows.

Cheng indicated, “A key requirement is to address the applications where programmable eFPGA functionality also incorporates significant memory storage. Many customers are seeking a product that optimally integrates SRAM within the eFPGA logic tiles. They do not intend to invest a lot of resource in physical implementation – i.e., designing and floorplanning SRAM blocks adjacent to the eFPGA IP. These customers want a flow from their HDL description through synthesis to an off-the-shelf eFPGA product with programmable logic and memory.”

“To that end, we will soon be releasing an integrated design for silicon qualification, as a standard product.”, Aparna highlighted.

Tony added,“With lots of customer input, we have selected a combination of programmable logic capacity and array storage that will span a wide range of upcoming customer designs. We are leveraging the existing HDL synthesis flow support that provides block RAM’s in the output netlist, inferring the array topology from the HDL model. Our EFLX compiler maps each BRAM in the synthesis netlist to a corresponding configuration of SRAM macros integrated in the eFPGA IP.”

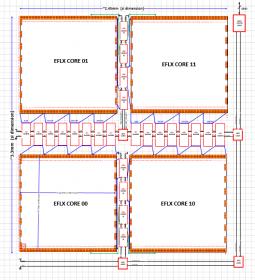

The use of Block RAM’s is the standard representation for synthesizing and implementing arrays for commercial FPGA products – so, this flow is a natural extension for eFPGA IP.The initial Flex Logix programmable logic + array offering is illustrated below.

Aparna is the lead designer, and provided a description of some of the technical features:

- eFPGA array macros are based on qualified TSMC bit cells. (The initial process node will be 28nm.)

- MBIST test controller design logic is provided.

- The array macros are optimally configured between tiles – specific attention is given to the I/O connections from the tiles to the arrays, without adversely impacting the logic signal routing capacity between tiles.

- The EFLX placement algorithm will automatically assign the BRAM netlist instances to the integrated SRAM macros, leveraging timing-driven optimization calculations. (Unused array macros are tied to inactive levels.)

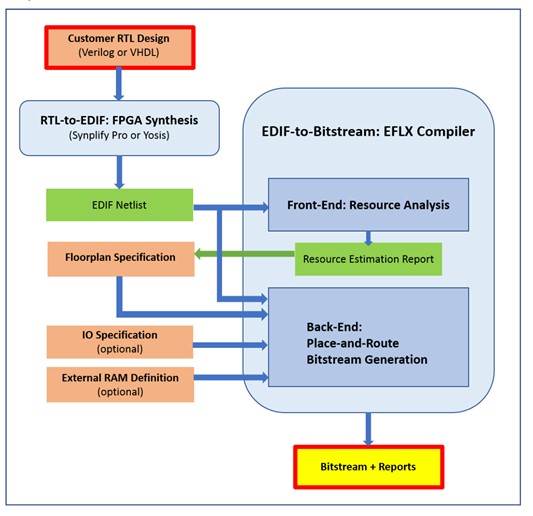

The overall flow for realizing the eFPGA logic + memory design is illustrated in the figure below.

The initial front-end EFLX analysis step provides customers with resource estimates, for both the programmable logic LUT usage and the array macro utilization. The subsequent steps complete the physical personalization, including the array macro connectivity.

“Our customers are seeking silicon-proven IP products – this offering will expand the application base to designs requiring integrated storage.”, Cheng said. (For specific customers who are interested in a unique integrated configuration, the Flex Logix team would assist them with preparation of the flow input descriptions shown as “optional” in the figure above, as well as the IP physical implementation.)

So, it looks like the eFPGA technology market is indeed expanding to offer customers with product(s) that will accelerate adoption, combining complex logic and storage requirements with a well-defined implementation flow. This past year has indeed been the “year of the eFPGA” – it will be interesting to see what 2018 brings.

For more information on the Flex Logix logic + array offering, please follow this link.

Have a Happy Holiday season!

-chipguy

Share this post via:

Comments

There are no comments yet.

You must register or log in to view/post comments.