Certus Semiconductor Brings High-Performance Custom I/O and ESD IP to DAC 2025

Certus Semiconductor, a trusted leader in custom I/O and ESD solutions, will exhibit at booth #1731 during DAC 2025, June 23–27 in San Francisco. Known for its robust, customer-proven IP tailored for challenging applications, Certus will highlight… Read More

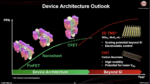

TSMC N3 Process Technology Wiki