Moore’s Law has been about device density, specifically transistor density, increasing every certain number of years. Although cost is the most easily grasped advantage, there are two other benefits: higher performance (speed) and reduced power. When these benefits are compromised, they can also pose a scaling limitation.

The Uncertain Phase Shifts of EUV Masks

EUV (Extreme UltraViolet) lithography has received attention within the semiconductor industry since its development inception in 1997 with the formation of the EUV LLC [1], and more recently, since the 7nm node began, with limited use by Samsung and TSMC being touted as key advantages [2, 3]. As with any key critical technology,

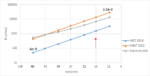

MOSFET Gate Length Scaling Limit at Reduced Threshold Voltages

As transistor dimensions shrink to follow Moore’s Law, the functionality of the gate used to switch on or off the current is actually being degraded by the short channel effect (SCE) [1-5]. Moreover, the simultaneous reduction of voltage aggravates the degradation, as will be discussed below.

A Practical Lower Limit of… Read More

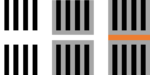

Reliable Line Cutting for Spacer-based Patterning

Spacer-defined patterning is an expected requirement for advanced semiconductor patterning nodes with feature sizes of 25 nm or less. As the required gaps between features go well below the lithography tool’s resolution limit, the use of cut exposures to separate features is used more often, especially in chips produced… Read More

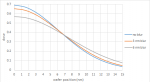

Lithography Resolution Limits: Line End Gaps

In a previous article [1], the Rayleigh criterion was mentioned as the resolution limit for the distance between two features. On the other hand, in a following article [2], the minimum pitch was mentioned for the resolution limit for arrayed features. In this article, we reconcile the two by considering gaps between arrayed features,… Read More

ASML A Scenario More Lumpy While Demand and Tech Remain Solid Despite Covid Delays

Covid issues create “lumpy” quarters due to delays

Orders & demand remain solid and strong

2020 Year financials intact so far but ignore Qtrs

Taking prudent actions- no buybacks or guidance

As expected, Covid impacts both shipments & supply chain, ignore the near term lumpiness…

ASML reported revenues… Read More

SPIE 2020 – ASML EUV and Inspection Update

I couldn’t attend the SPIE Advanced Lithography Conference this year for personal reasons, but last week Mike Lercel of ASML was nice enough to walk me through the major ASML presentations from the conference.

Introduction

In late 2018, Samsung and TSMC introduced 7nm foundry logic processes with 5 to 7 EUV layers, throughout … Read More

Lithography Resolution Limits – Arrayed Features

State-of-the-art chips will always include some portions which are memory arrays, which also happen to be the densest portions of the chip. Arrayed features are the main targets for lithography evaluation, as the feature pitch is well-defined, and is directly linked to the cost scaling (more features per wafer) from generation… Read More

Lithography Resolution Limits: Paired Features

As any semiconductor process advances to the next generation or “node”, a sticky point is how to achieve the required higher resolution. As noted in another article [1], multipatterning (the required use of repeated patterning steps for a particular feature) has been practiced already for many years, and many have… Read More

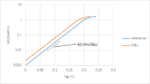

Low Energy Electrons Set the Limits for EUV Lithography

EUV lithography is widely perceived to be the obvious choice to replace DUV lithography due to the shorter wavelength(s) used. However, there’s a devil in the details, or a catch if you will.

Electrons have the last word

The resist exposure is completed by the release of electrons following the absorption of the EUV photon.… Read More

Real men have fabs!