Automatic adaptive meshing in HFSS is a critical component of its advanced simulation process. Guided by Maxwell’s Equations, it efficiently refines the mesh to accurately capture both the geometric and electromagnetic detail of a design. The end result is a process that guarantees accurate and reliable simulation results with no user input required.

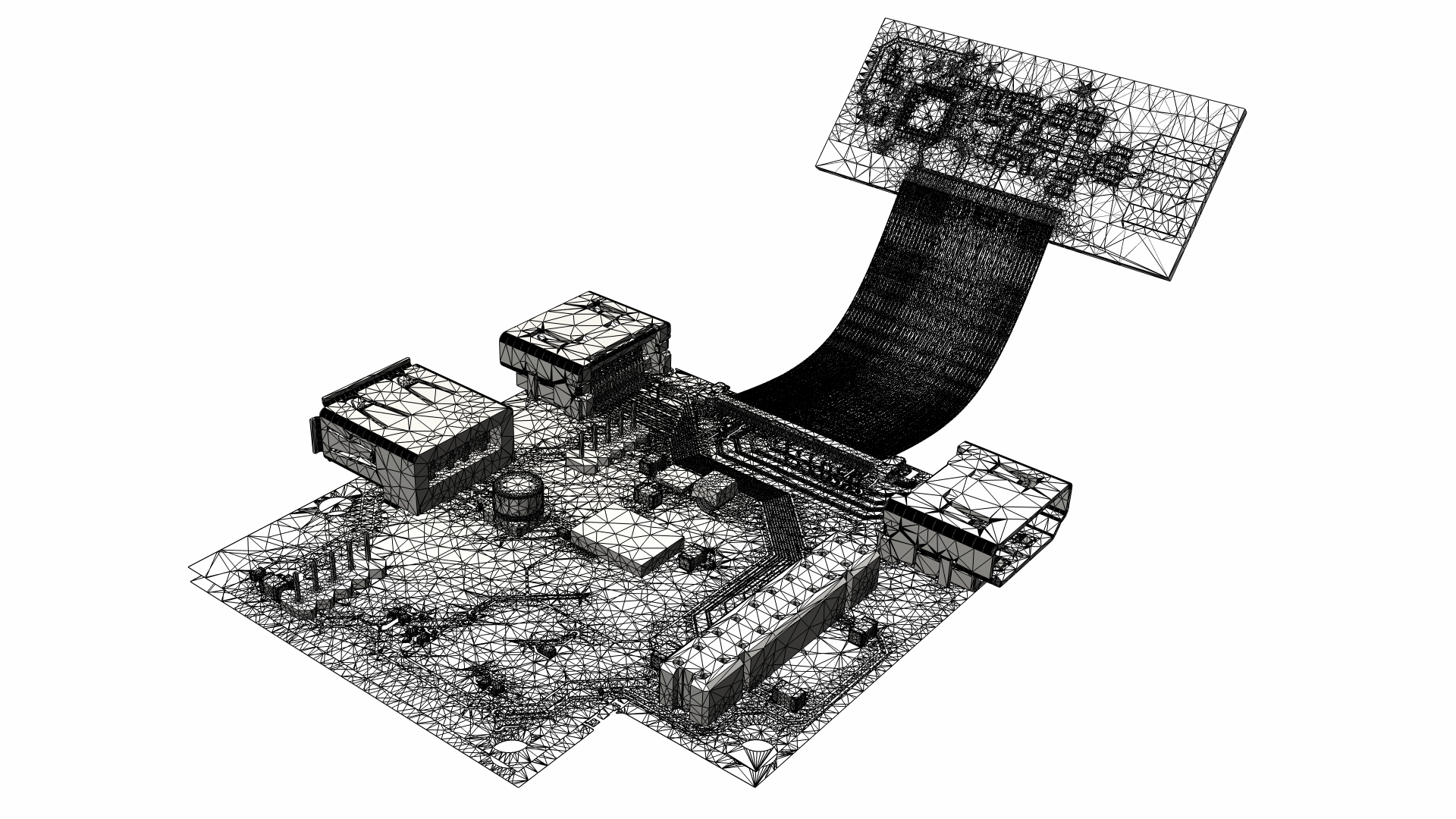

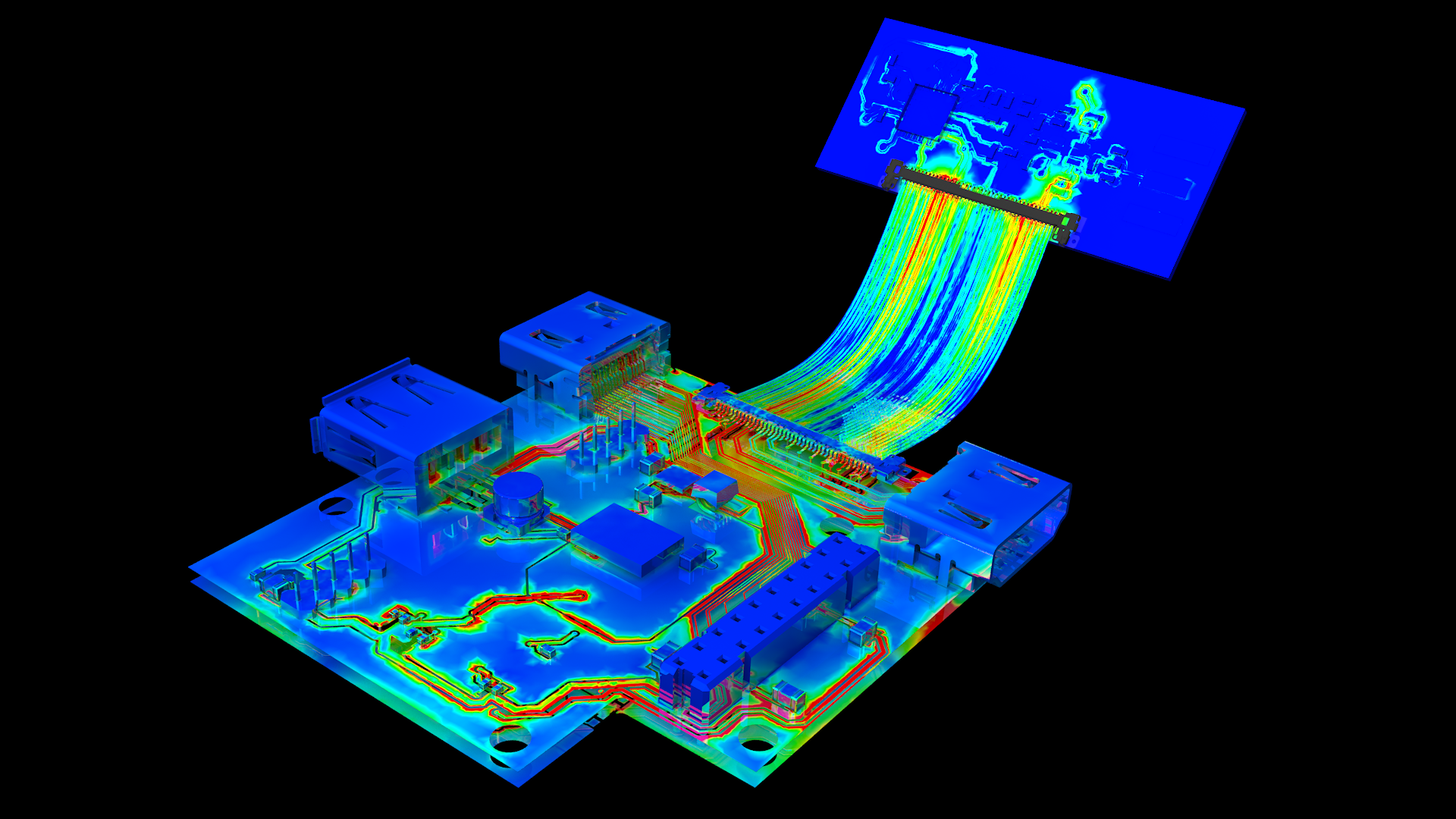

Before the adaptive meshing process can begin, there must be an initial mesh to faithfully represent the device’s geometry. With today’s highly dense and complex designs, creating this mesh can be a challenging task. A variety of initial meshing approaches are available in HFSS, each with a different scheme for mesh generation and a different set of strengths, apropos for different design types. For example, the TAU meshing technology is well suited for meshing complex 3D CAD while the Phi meshing technology is highly effective for meshing PCBs. Attempting to apply a one-mesh-fits-all paradigm is a significant challenge when approaching complex designs containing a mixture of CAD, like a PCB in a shielding enclosure.

Fortunately, today HFSS uses the new breakthrough HFSS Mesh Fusion technology to apply meshing approaches according to local CAD specifications. From there, HFSS proceeds with the same reliable, adaptive refinement process with guaranteed accuracy.

Figure 1. HFSS Mesh Fusion applied to PCB-Connector-Flex System. Mesh-left, Fields-right

Phi is one of the meshing techniques that Mesh Fusion can apply to local CAD for components like PCBs and IC packaging. Phi is “geometry-aware.” It works with designs that are composed of 2D layers uniformly swept in their normal. When applied to the right CAD, such as a PCB, Phi is 10, 15, or even 20 times faster than its partner 3D meshing technologies—Classic and TAU.

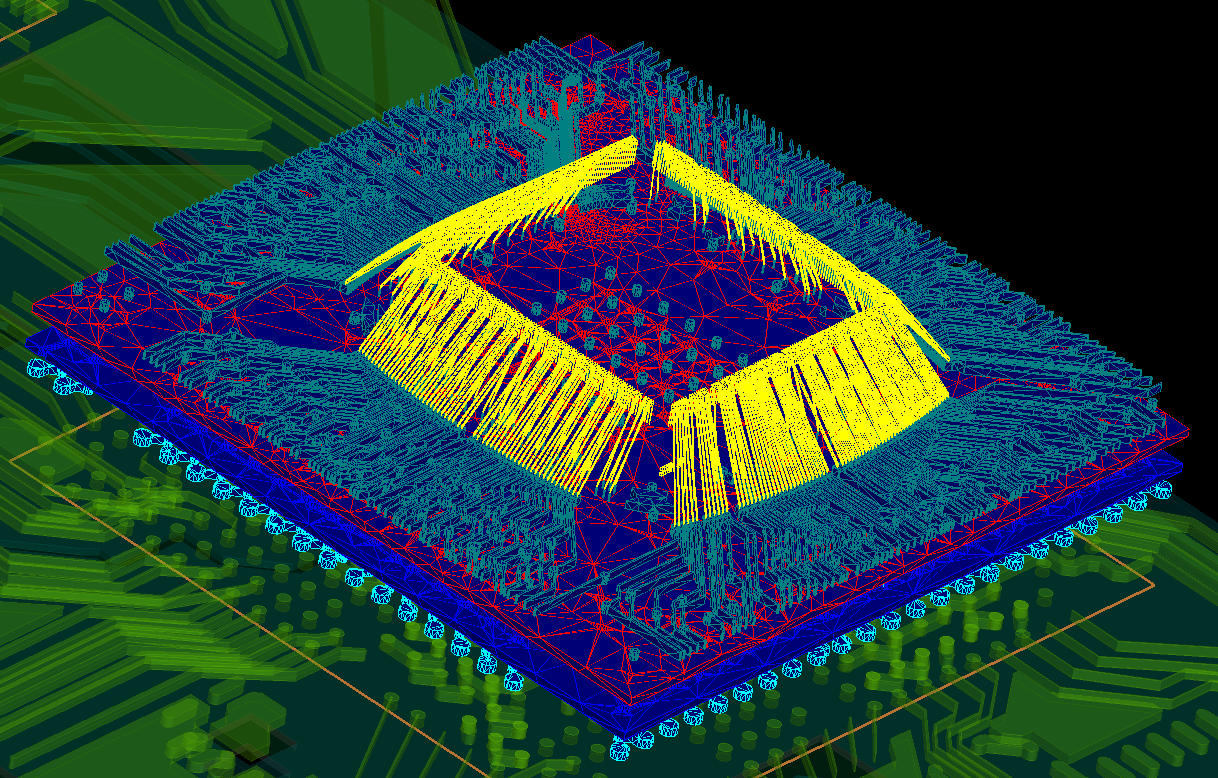

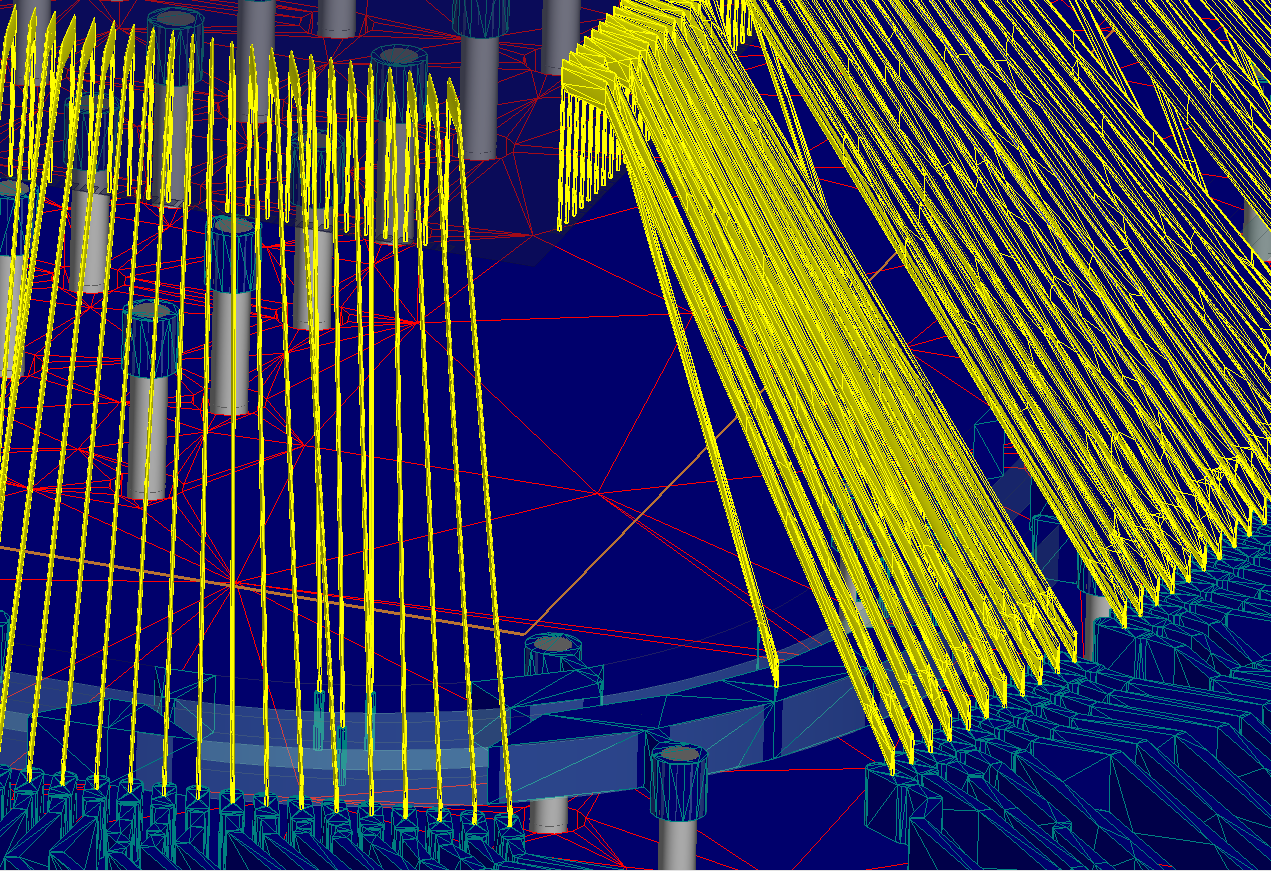

After two decades of meshing innovation, there were still a few “rogue” design types that were notoriously difficult to mesh—most notably a common, inexpensive design solution in consumer electronics: wirebond packaging. With tiny, high-aspect-ratio copper wires connecting to an integrated circuit inside the package, its design is both layered and 3D in nature. These two CAD features, when combined in a single design, were challenging for the existing meshing technologies to manage…until now.

Introducing Phi Plus

Ansys created Phi Plus using a ground-up approach for new meshing technology, specifically designed for challenging mixed geometries like wirebond packaging. Like its predecessor, Phi, it’s “geometry-aware.” It was designed specifically to understand how wirebond packages, and other complicated 3D components like PCB connectors, are manufactured and assembled. Phi Plus takes advantage of this design knowledge and accounts for those nuances in the meshing model.

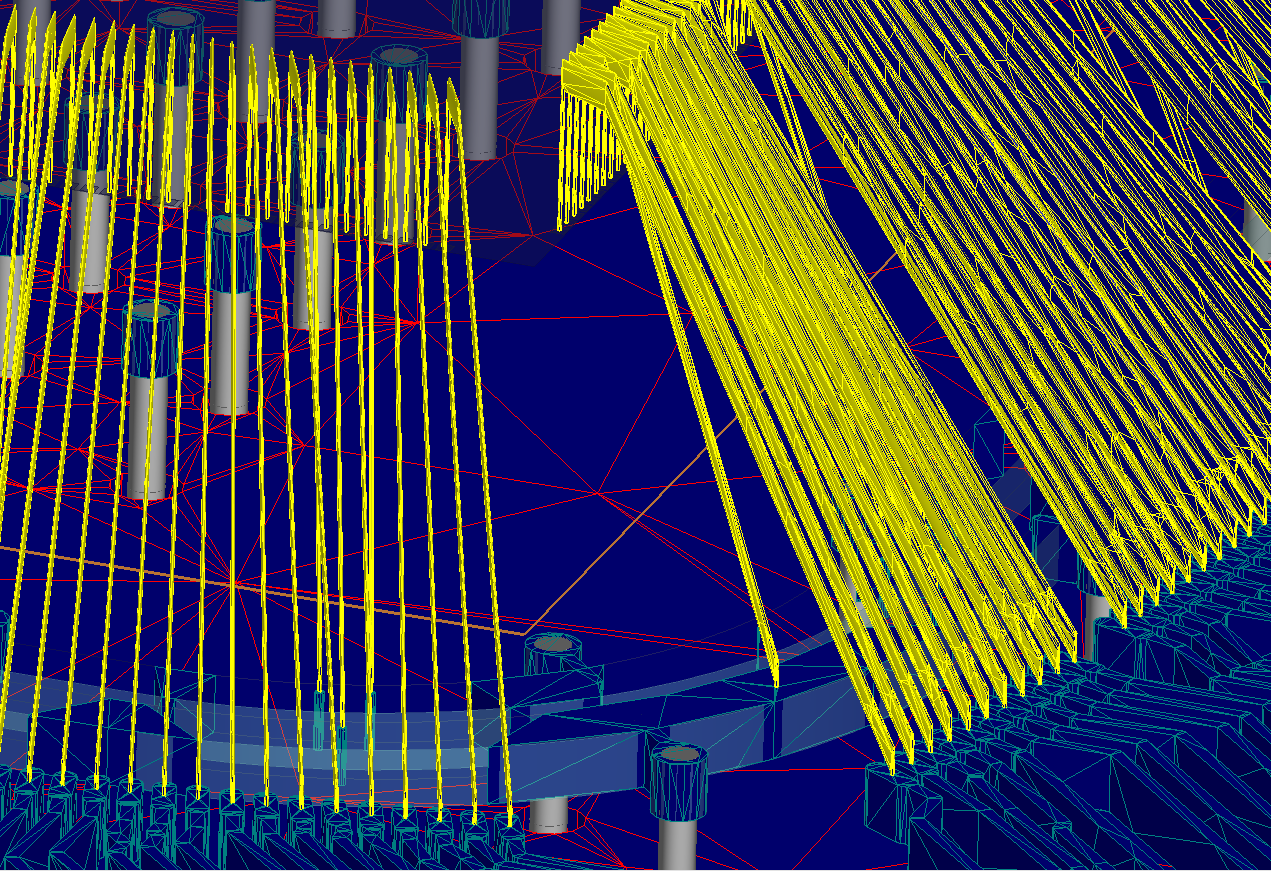

Figure 2. Package on PCB system meshed with Phi Plus and HFSS Mesh Fusion. Z-stretched view

Key features include:

Parallel Meshing Technology

Ansys prioritized parallel meshing to speed up Phi Plus processing time. From the ground up, Phi Plus was designed to take advantage of parallel computational strategies; in beta, upwards of 10 times faster mesh times were observed when meshing with 12 cores.

Robustness and Reliability

Phi Plus combines the reliability of Phi with component-specific considerations to control for a uniform, high-quality, and water-tight mesh. A higher quality mesh generates downstream benefits in the adaptive meshing and frequency sweep solving steps. Benefits include smaller final mesh count, less solution memory, and the ability to solve more frequency points in parallel for a faster total speed with high performance computing (HPC) resources.

Figure 3. Close-up view of wirebond at top layer of package

More Than “Just” Fast

With no change to user flow, the entire simulation process can be upwards of 10 times faster with little to no mesh failures. For now, implementation requires a single settings change in simulation set up with no other action needed from the user. Phi Plus has proven to be so robust in its beta rollout that it’s anticipated to become the default meshing approach in a near-future release.

It doesn’t stop with “just” wirebond packages either. Phi Plus addresses system complexity that wasn’t possible before. Its robust meshing capabilities can manage other common 3D effects in complex electronics design, including trace etching or the inclusion of 3D Encrypted Components.

The Bottom Line

However beautifully rendered a 3D design may look on the computer screen, it’s the mesh that dictates what’s simulated. Mesh is foundational to an accurate physics model. HFSS has a long legacy of letting Maxwell’s Equations guide the creation of accurate, efficient mesh, and that legacy grows stronger with the advent of Phi Plus. With Ansys HFSS 2022 R1, Phi Plus meshing will be fully incorporated into our system-capable Mesh Fusion technology. Combined with hyper-scale technologies like Ansys Cloud, there are no limits to what teams can tackle with Ansys HFSS.

Also Read

Optical I/O Solutions for Next-Generation Computing Systems

Neural Network Growth Requires Unprecedented Semiconductor Scaling

SeaScape: EDA Platform for a Distributed Future

Share this post via:

Comments

There are no comments yet.

You must register or log in to view/post comments.