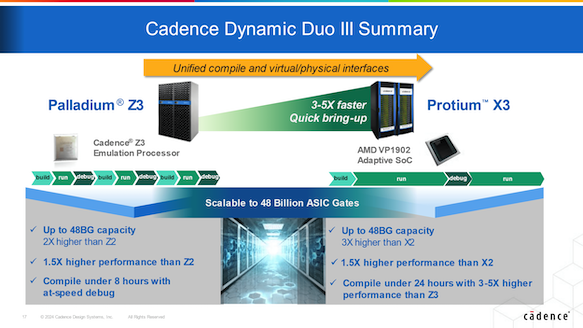

The relentless pursuit for maximizing performance in semiconductor development is now matched by the crucial need to minimize energy consumption.

Traditional simulation-based power analysis methods face insurmountable challenges to accurately capture complex designs activities in real-world scenarios. As the scale… Read More

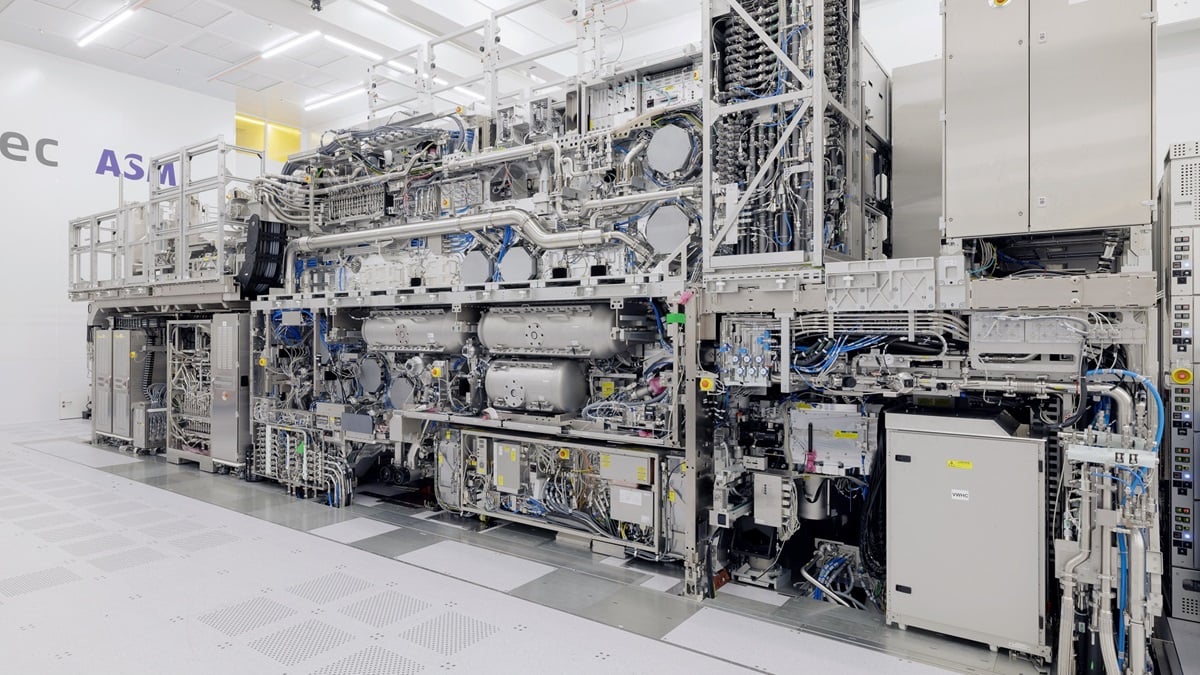

Real men have fabs!