Chipmakers need speed; ASML is here to deliver.

(Image credit: ASML)

This week, ASML delivered its 3rd Generation extreme ultraviolet (EUV) lithography tool, the Twinscan NXE:3800E, with a projection lens featuring a 0.33 numerical aperture. The system significantly increases performance compared to the existing Twinscan NXE:3600D machine. It is designed for fabricating chips at leading-edge technologies, including 3nm, 2nm, and small nodes in the next few years.

The ASML Twinscan NXE:3800E represents a leap forward in Low-NA EUV lithography regarding performance (the number of wafers processed per hour) and matched machined overlay. The new system can process over 195 wafers per hour at a 30 mJ/cm^2 dose and promises a further increase in performance to 220 wph with a throughput upgrade. In addition, the new tool offers a less than 1.1 nm-matched machine overlay (wafer alignment accuracy).

"Chipmakers have a need for speed," ASML revealed in a statement published on X. "The first Twinscan NXE:3800E is now being installed in a chip fab. With its new wafer stages, the system will deliver leading edge productivity for printing advanced chips. We are pushing lithography to new limits."

Increased throughput will increase the economic efficiency of the Twinscan NXE:3800E machine when producing chips on 4nm/5nm and 3nm-class process technologies for logic makers. The improved performance of ASML's Twinscan NXE:3800E is expected to significantly mitigate one of the primary drawbacks of EUV technology, which is its relatively low performance, thereby enabling more efficient and cost-effective chip production. This will make process technologies that rely on EUV more accessible to chip designers with budgets that are not as vast as those of Apple, AMD, Intel, Nvidia, and Qualcomm. Also, the tool will be crucial for memory makers such as Micron, Samsung, and SK Hynix.

In addition, the Twinscan NXE:3800E's enhanced performance will be particularly useful for making chips on 2nm and subsequent classes of fabrication technologies that will need EUV double patterning. Improvements in the matched machine overlay will benefit sub-3nm-class production nodes.

(Image credit: ASML)

However, the sophistication and capabilities of machines like the NXE:3800E come at a substantial cost, with a price tag of around $180 million each. Such high costs mean it takes some time to depreciate the costs of these lithography tools. However, for ASML's clientele, which comprises a select group of significant logic and memory fabrication companies, the NXE:3800E offers a path to bolster their production capabilities of cutting-edge chips. This is crucial for these companies as they strive to meet the growing global demand for semiconductors, expand their production capacities, and manage the economics of chip manufacturing. Introducing more advanced and efficient EUV scanners like the NXE:3800E is critical to achieving these objectives.

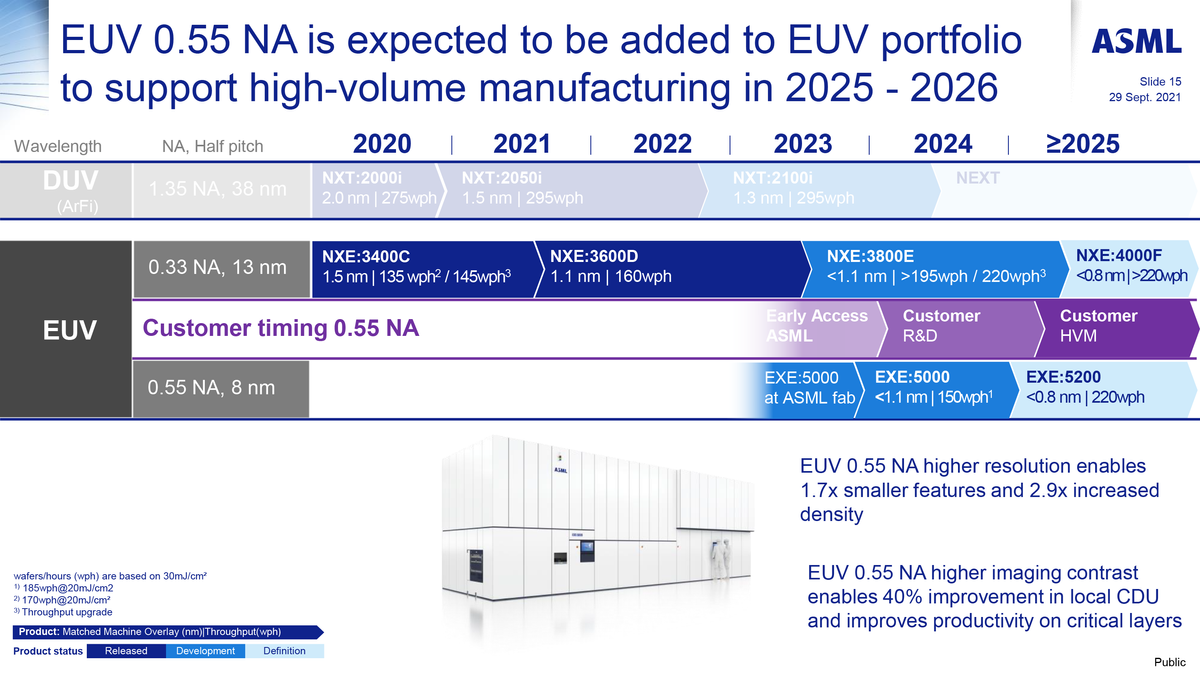

Looking ahead, ASML is not resting on its laurels, with plans for further innovation in the form of the Twinscan NXE:4000F, another generation of Low-NA EUV scanner, slated for release around 2026. This ongoing development underscores ASML's commitment to advancing Low-NA EUV manufacturing technology despite the looming adoption of High-NA litho tools.

www.tomshardware.com

www.tomshardware.com

(Image credit: ASML)

This week, ASML delivered its 3rd Generation extreme ultraviolet (EUV) lithography tool, the Twinscan NXE:3800E, with a projection lens featuring a 0.33 numerical aperture. The system significantly increases performance compared to the existing Twinscan NXE:3600D machine. It is designed for fabricating chips at leading-edge technologies, including 3nm, 2nm, and small nodes in the next few years.

The ASML Twinscan NXE:3800E represents a leap forward in Low-NA EUV lithography regarding performance (the number of wafers processed per hour) and matched machined overlay. The new system can process over 195 wafers per hour at a 30 mJ/cm^2 dose and promises a further increase in performance to 220 wph with a throughput upgrade. In addition, the new tool offers a less than 1.1 nm-matched machine overlay (wafer alignment accuracy).

"Chipmakers have a need for speed," ASML revealed in a statement published on X. "The first Twinscan NXE:3800E is now being installed in a chip fab. With its new wafer stages, the system will deliver leading edge productivity for printing advanced chips. We are pushing lithography to new limits."

Increased throughput will increase the economic efficiency of the Twinscan NXE:3800E machine when producing chips on 4nm/5nm and 3nm-class process technologies for logic makers. The improved performance of ASML's Twinscan NXE:3800E is expected to significantly mitigate one of the primary drawbacks of EUV technology, which is its relatively low performance, thereby enabling more efficient and cost-effective chip production. This will make process technologies that rely on EUV more accessible to chip designers with budgets that are not as vast as those of Apple, AMD, Intel, Nvidia, and Qualcomm. Also, the tool will be crucial for memory makers such as Micron, Samsung, and SK Hynix.

In addition, the Twinscan NXE:3800E's enhanced performance will be particularly useful for making chips on 2nm and subsequent classes of fabrication technologies that will need EUV double patterning. Improvements in the matched machine overlay will benefit sub-3nm-class production nodes.

(Image credit: ASML)

However, the sophistication and capabilities of machines like the NXE:3800E come at a substantial cost, with a price tag of around $180 million each. Such high costs mean it takes some time to depreciate the costs of these lithography tools. However, for ASML's clientele, which comprises a select group of significant logic and memory fabrication companies, the NXE:3800E offers a path to bolster their production capabilities of cutting-edge chips. This is crucial for these companies as they strive to meet the growing global demand for semiconductors, expand their production capacities, and manage the economics of chip manufacturing. Introducing more advanced and efficient EUV scanners like the NXE:3800E is critical to achieving these objectives.

Looking ahead, ASML is not resting on its laurels, with plans for further innovation in the form of the Twinscan NXE:4000F, another generation of Low-NA EUV scanner, slated for release around 2026. This ongoing development underscores ASML's commitment to advancing Low-NA EUV manufacturing technology despite the looming adoption of High-NA litho tools.

ASML delivers cutting-edge new chipmaking tool — third-generation EUV enables 2nm processors and beyond

Chipmakers need speed; ASML is here to deliver.