Whether it is the stock market or the semiconductor market, the name of the game is yield. In semiconductors, yield has to do with minimizing scrap costs in all phases of manufacturing. This means squeezing as many good dies from a wafer as well as maximizing the number of good assembled/packaged chips that pass system level testing. Naturally, the field of semiconductor yield management is a well-established space with a number of solutions offered by various vendors. One such vendor, solely focused on yield management and enhancement is yieldHUB. It is one thing for a vendor to tout their wares but when customers tout a vendor’s platform, it raises more attention.

A couple of customers recently shared with yieldHUB, detailed feedback about their experience with yieldHub’s platform. One of them is Infineon, a multi-national semiconductor technology company that develops products for commercial, industrial, automotive, aerospace and defense applications. Their products include high-performance memories, micro-controllers, energy efficient and intelligent power modules, sensors, charging devices, lighting, audio, connectivity and hardware-based security devices. The other customer is Clas-SiC Wafer Fab Ltd, the first open foundry to develop and prototype silicon carbide (SiC) diode and MOSFET devices. The use cases from these two customers is bound to face as many of the yield management challenges there are.

Infineon’s Feedback:

Charbel Abi Samra Product Engineering Manager at Infineon and a long-time yieldHUB user provides the following feedback.

yieldHUB as an all-in-one platform eliminates the need for use of various point tools to get the same results. With yieldHUB, problems can be quickly identified and solved by searching its database and analyzing in just a few clicks. The earlier solution that Infineon used to use for yield management wasn’t efficient. Engineers had to jump back and forth between the query program, analysis program and data management in-between. As an example, on a customer request to tighten a limit, the analysis was done in less than 2 minutes with yieldHUB. Using the earlier solution, it would have taken two hours to locate the data and plot it.

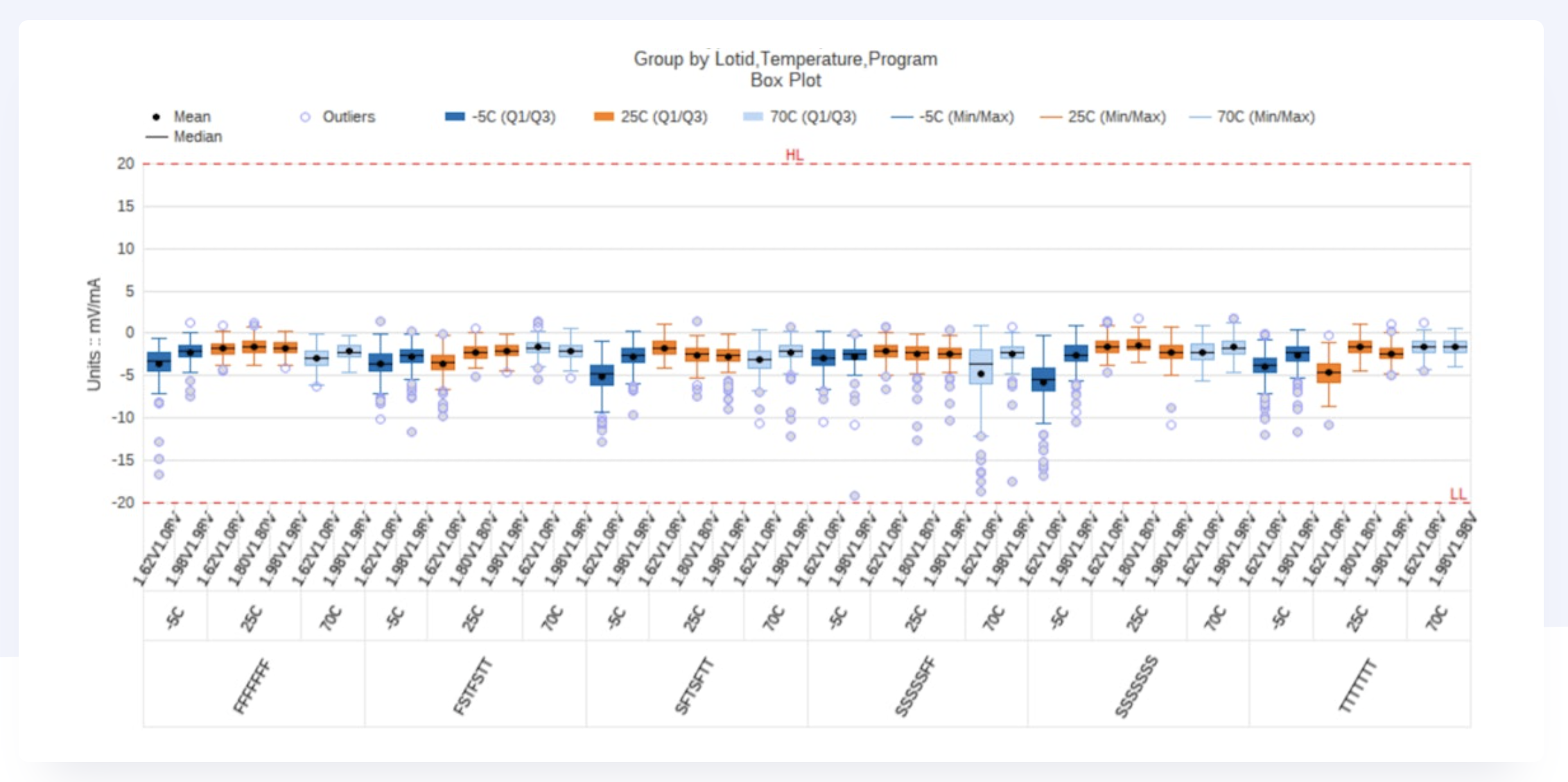

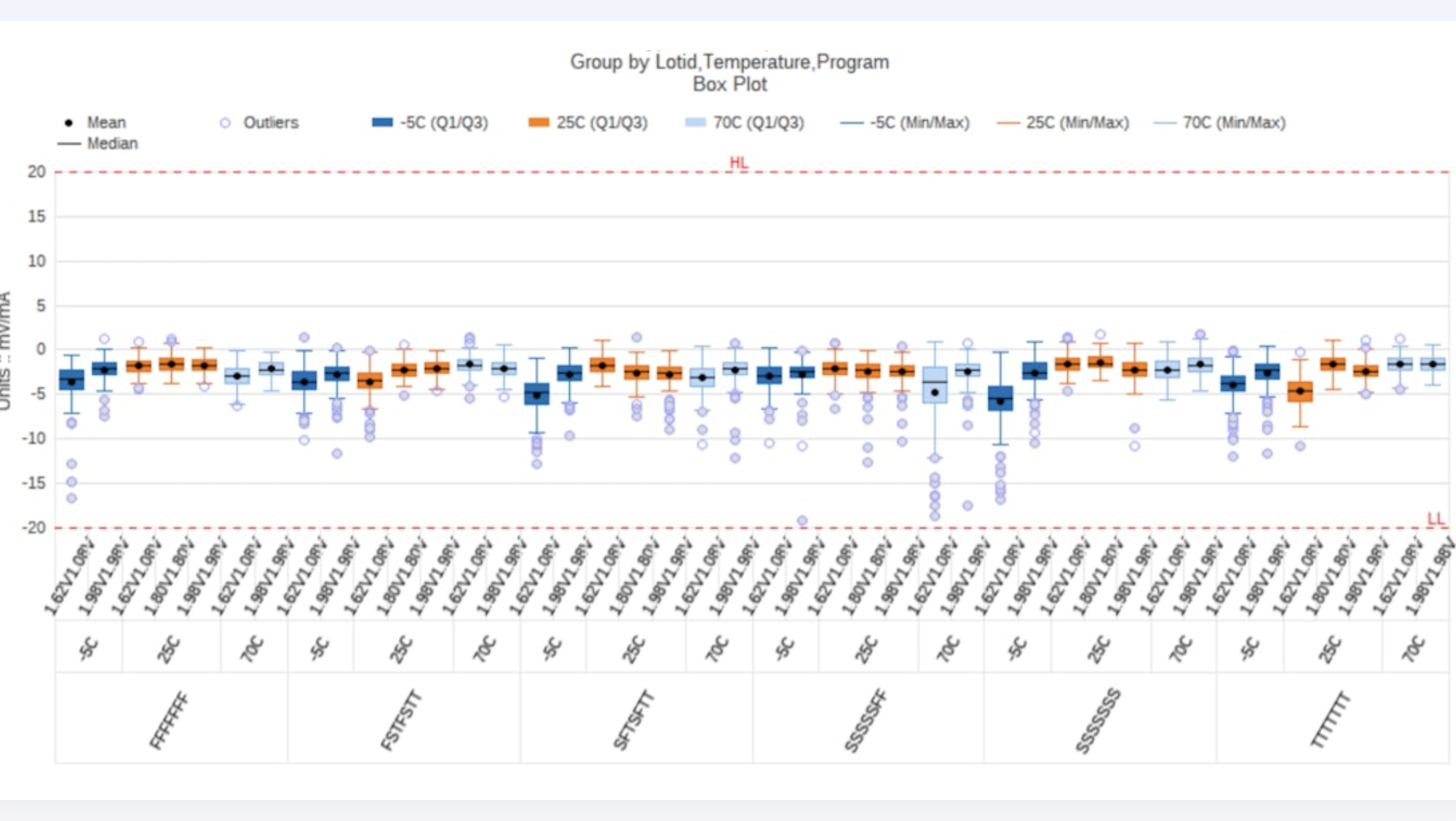

yieldHUB’s custom reporting tools allow Infineon to reduce customer returns and field failures. Another yieldHUB tool increases our customers’ satisfaction levels by simplifying the test data sent to them in a consolidated fashion as one file. Another valuable feature in yieldHUB that product engineers will greatly appreciate is creating box plots and grouping multiple lots together. This feature allows the engineers to review the product’s history and the failure pareto.

Clas-SiC Wafer Fab Ltd’s Feedback:

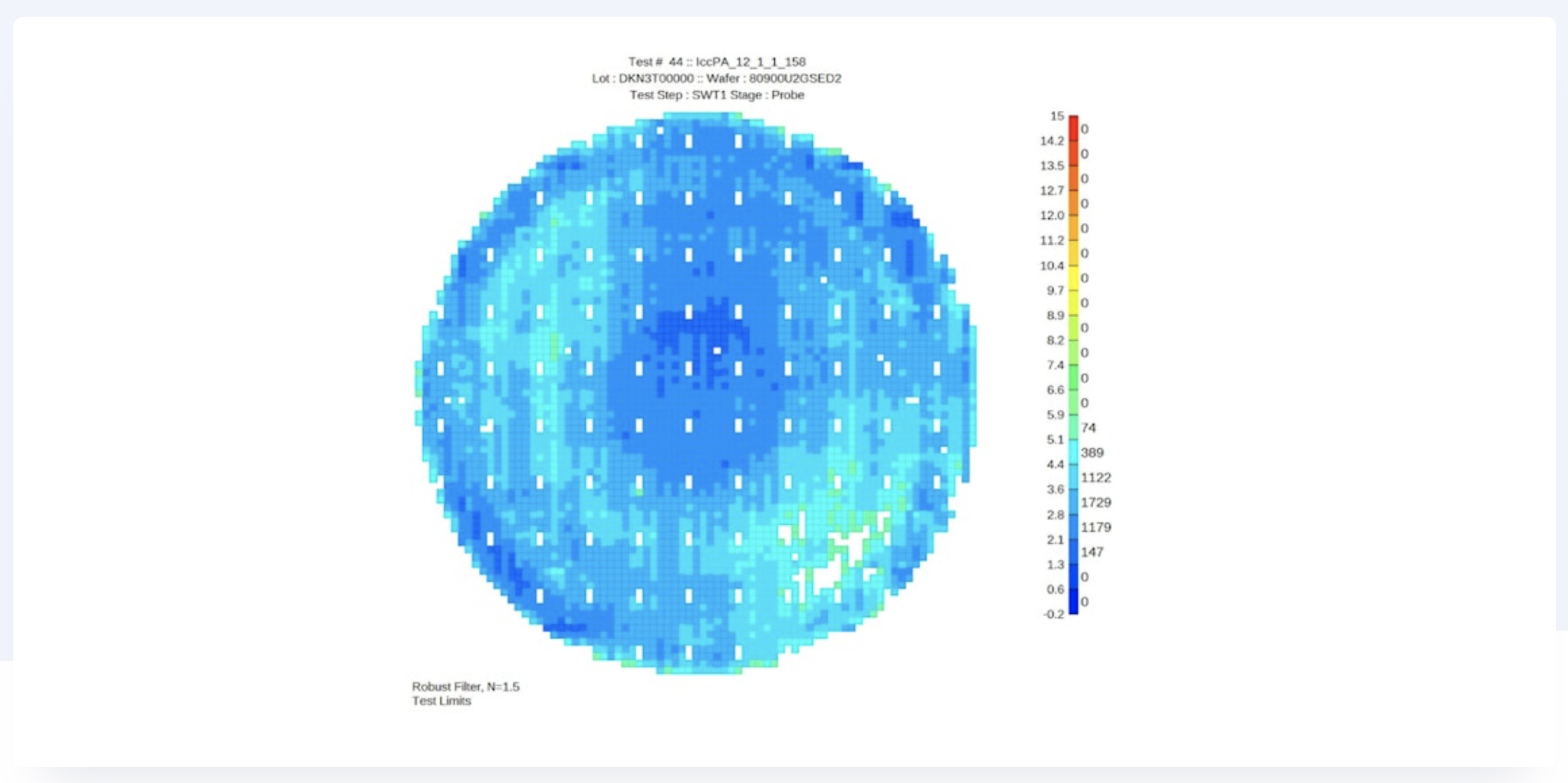

Clas-SiC Wafer Fab Ltd manufactures SiC wafers through Junction Barrier Schottky (JBS) diode [also known as Merged PN Schottky (MPS) diode] and MOSFET process flows. The amount of data that needs to be analyzed to make sure everything is functioning properly is more than Excel can handle time efficiently. We needed a yield management platform to enable us to meet our customers’ functional requirements as well as turnaround time requirements. Clas-SiC needed a solution that provides for a quick graphical representation of the analytical results in a format easy to convey to our customers.

yieldHUB onboarding is very fast and straightforward. According to Graeme Morland, Clas-SiC Manufacturing Excellence Engineering and Quality Manager, Clas-SiC was online the very next day after yieldHUB was installed. Rae Hyndman, Clas-SiC Managing Director says the speed at which yieldHUB’s wafer yield analysis software integrated with Clas-SiC’s test system’s results was remarkable.

What used to take a couple of hours of an engineer’s time now takes just a couple of minutes when using yieldHUB. The yieldHUB platform has certainly fast tracked things for Clas-SiC. While it usually takes four to eight weeks to make a customer’s product, yieldHUB has helped get the information to the end-customers faster on several occasions.

Summary

yieldHUB makes the task of yield management, data analysis and reporting easier, effective and efficient. Anyone tasked with the responsibility of ensuring product performance and yields of semiconductor products could benefit from using the yieldHUB platform.

To gain more insight into yieldHub’s products and services, visit yieldHub website.

Also Read:

The Six Signs That You Need a Yield Management System

yieldHUB – Helping Semiconductor Companies be More Competitive

yieldHUB – A Yield Management Checklist for Startups and a New Look

Share this post via:

Comments

There are no comments yet.

You must register or log in to view/post comments.