The automotive industry is undergoing a major transformation. The convergence of electrification, connectivity, driver-assistance technologies, and software-defined vehicles has led to the rise of use of advanced System-on-Chips (SoCs) that drive unprecedented levels of functionality and performance. However, this transformation also raises concerns about the safety and reliability of these complex systems. This shift presents unique challenges and opportunities in ensuring the performance, reliability, and safety of automotive systems. As automotive technology advances, the traditional approaches to functional safety face significant disruptions. The traditional reactive approach to functional safety, which involves addressing issues after they occur, is insufficient for the complex and interconnected automotive systems of today. Proactive approaches are needed for predicting failures, anticipating risks, and actively mitigating them before they cause significant disruptions. Maintaining the utmost resilience and operational efficiency of automotive systems, calls for continuous monitoring and predictive insights.

proteanTecs has published a whitepaper that explores the shifting landscape of automotive functional safety and the required methodologies to ensure the safe and reliable operation of these intricate automotive systems. The whitepaper delves into the implications of data-driven advancements in artificial intelligence, machine learning, and data analytics for automotive functional safety and useful life extension. It explores proactive approaches that transcend traditional reactive measures, enabling stakeholders to anticipate failures and proactively mitigate risks.

This whitepaper is an excellent read for everyone involved in the development and deployment of automotive functional safety systems. Following are some excerpts from that whitepaper.

Hardware Failure Anticipation through Prognostic Techniques

One of the key challenges in ensuring functional safety is anticipating hardware failures. With the application of prognostic techniques, which involve analyzing data to predict the future reliability of components or systems, automotive stakeholders can anticipate potential hardware failures. This allows them to take preventive measures before they occur, thus enhancing the safety and longevity of automotive systems.

Understanding the Impact of Defects on System Lifetime

Defects innate to manufacturing or caused by operating environment and usage patterns can significantly affect the lifetime of automotive systems. Analyzing defect-induced failures and understanding their occurrence can help in estimating the Failure Rate (FR) of electronic devices. Equipped with this insight, automotive manufacturers can focus on improving the reliability of electronic components, thereby ensuring the longevity of the systems and enhancing functional safety.

Time-To-Failure (TTF) Predictions and Reliability Improvement

Estimating the TTF is another critical aspect in understanding the reliability of automotive components and systems. TTF predictions involve monitoring device performance to estimate when a device will fail. By combining observed (empirical field data) and predicted failures, reliability parameters can be estimated more quickly. TTF predictions can be leveraged to gain insights into potential failure scenarios and take preemptive actions. These preemptive actions enhance the overall functional safety of automotive systems.

Leveraging Deep Data On-Chip Monitors and Degradation Modeling

Monitoring the margin degradation of Integrated Circuits (ICs) is essential to estimating FR and TTF of automotive systems. The implementation of deep data on-chip monitors and degradation modeling based on Physics-of-Failure principles are essential for continuous monitoring of ICs. This methodology provides real-time data for proactive decision-making and preemptive actions, thereby enhancing functional safety. The method involves using IC-embedded circuits called “Agents” strategically placed within the device to monitor degradation over time without interrupting normal operations. The Agents provide high-resolution data on chip parameters and degradation, allowing for the prediction of TTF for individual devices based on manufacturing parameters and mission history.

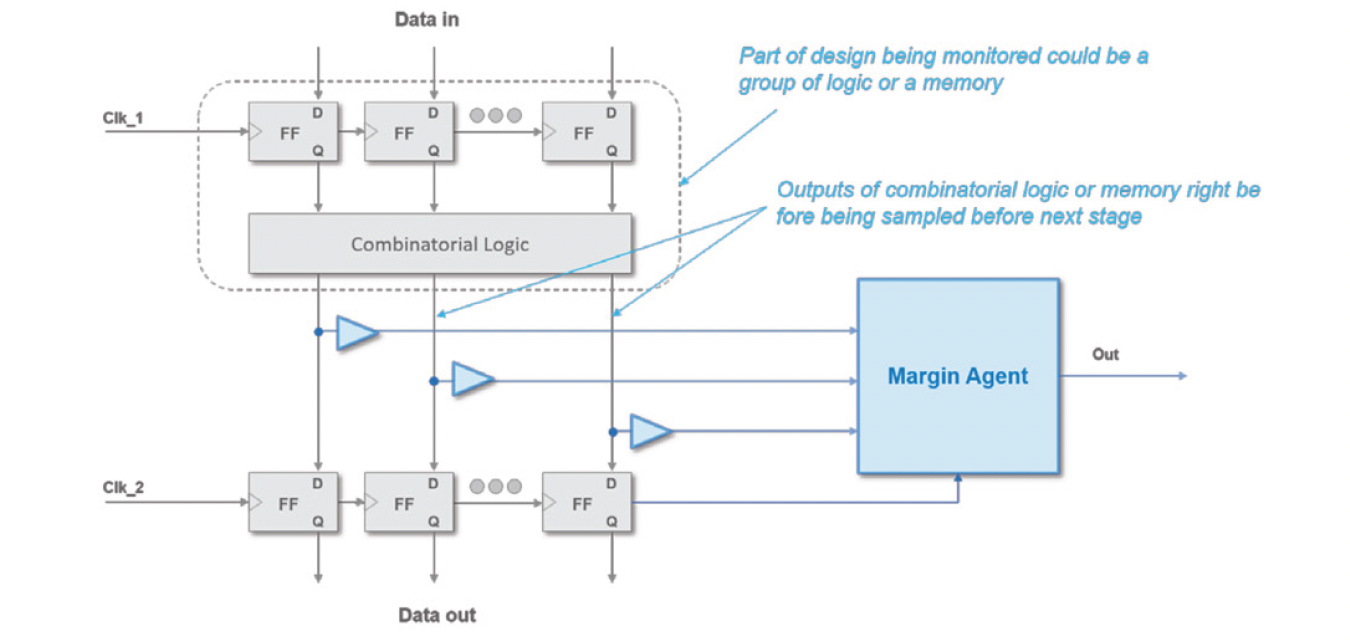

The Figure below shows how the Agents are connected to the monitored logic to measure timing margin of the logical paths.

During normal IC operations, the worst-case margin of the monitored logical paths is stored in the Agent and the data can be read at any time.

Estimating Remaining Useful Life (RUL) and Preventing Future Failures

By reading Agent data during reliability stress tests, the primary degradation mechanism can be determined, and TTF prediction algorithms can be used to estimate the remaining lifetime of devices. The ability to estimate RUL of automotive components is crucial for prescriptive measures and risk mitigation. Machine learning algorithms and predictive analytics can be applied to estimate RUL and prevent future failures. By identifying potential points of failure in advance, automotive manufacturers can implement preventive measures to ensure safety and operational efficiency.

Extending Useful Life

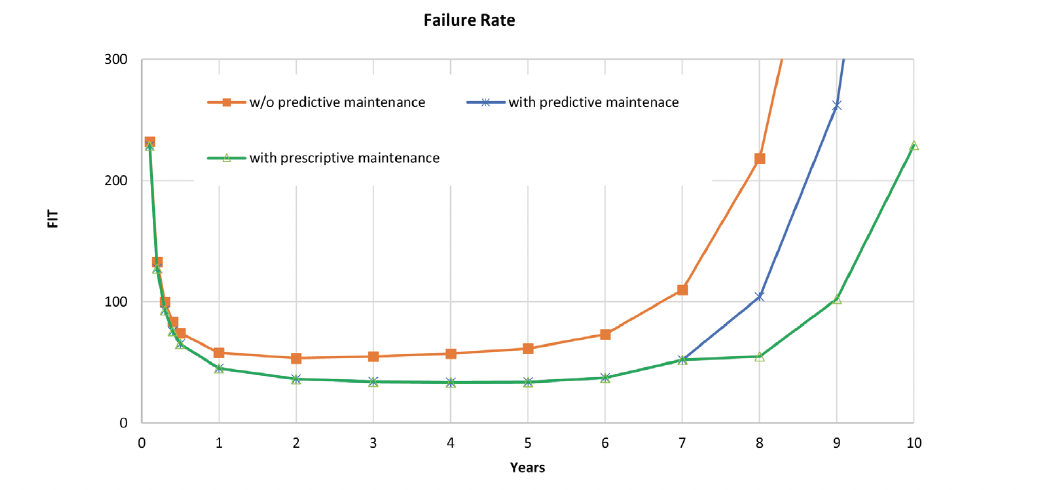

Prescriptive maintenance, which is another concept, recommends actions to change the future outcome by adapting the operational conditions of the device. While some intrinsic failures are difficult to predict, device aging can be modeled, and operational workload can be reduced to minimize stress. This may involve restricting software processes, adjusting voltage and frequency, or employing “limp-home mode” strategies. By reducing the operational stress, the occurrence of wear-out faults can be delayed, leading to an extended useful lifetime for the device.

The Figure below shows how a noticeable extension of useful life time can be achieved through a combination of predictive and prescriptive maintenance as the FR remains lower than 100 FIT for a longer period.

Summary

The ever-changing landscape of advanced SoCs in the automotive industry demands a fresh perspective on functional safety. Embracing proactive approaches, harnessing data-driven insights, and leveraging advanced techniques such as prognostics, degradation modeling, and predictive analytics are essential to support the transforming auto industry. By embracing continuous monitoring and predictive insights, automotive manufacturers and OEMs can achieve unprecedented levels of resilience, robustness, and operational efficiency from ICs to ECUs.

You can download the entire whitepaper from here. To learn more about proteanTecs technology and solutions, visit www.proteanTecs.com.

By ensuring the utmost performance, reliability, and safety of automotive systems, stakeholders can unlock the full potential of electrification, connectivity, and driver-assistance technologies while addressing the functional safety challenges of the modern automotive landscape.

Also Read:

Maintaining Vehicles of the Future Using Deep Data Analytics

Webinar: The Data Revolution of Semiconductor Production

Share this post via:

Comments

There are no comments yet.

You must register or log in to view/post comments.