If you look real close at the #49 DAC floor plan you will see the tiny Intel booth dwarfed by those of TSMC, GlobalFoundries, Samsung, and ARM. The number one semiconductor company in the world does not have the budget for the cornerstone conference of the semiconductor ecosystem? Oh my…… Intel has a big foundry hat and no cattle this year.

Now in its 49th year (this will be my 29[SUP]th[/SUP]), the Design Automation Conference features a wide array of technical presentations, tutorials, and workshops, as well as more than 200 of the leading semiconductor ecosystem partners in a colorful, well-attended trade show that attracts thousands of semiconductor professionals from around the world.

This year, industry luminaries from ARM, Inc., IBM Corp., Intel Corp. and the National Tsing Hua University will give the three keynote addresses. DAC 2012 will be held at my absolute favorite venue, other than Las Vegas, the Moscone Center in San Francisco, California, from June 3-7, 2012.

“In assembling the 49th DAC series of distinguished keynotes speakers, I am excited to announce that DAC is covering all bases, providing refreshing viewpoints for systems designers, IC designers and EDA software professionals,” said Patrick Groeneveld, General Chair of the 49th DAC.

“Tuesday kicks off with ARM’s Mike Muller, who will share his vision for a future of embedded computing systems. Given that ARM’s processors power most smartphones, this will show the way for computing in the future.”

“On Wednesday, Joshua Friedrich and Brad Heaney will outline the design practices for high-performance microprocessors. This unique dual-keynote provides a look in the kitchen of leading microprocessor companies designing the world’s most advanced chips,” Patrick enthusiastically continued.

“Finally, the Thursday keynote by Kaufman Award winner Dave Liu addresses the algorithmic revolution behind EDA. Prof. Liu’s contributions and insights have enabled the remarkable design automation revolution that actually powers today’s trillion-transistor devices.”

Keynote Schedule:

All keynotes will be held in rooms 102/103.

Tuesday, June 5, 2012 from 8:30am to 9:30am

Scaling for 2020 solutions

Mike Muller, CTO, ARM Inc., Cambridge, U.K.

Comparing the original ARM design of 1985 to those of today’s latest microprocessors, Mike will look at how far design has come and what EDA has contributed to enabling these advances in systems, hardware, operating systems, and applications as well as how business models have evolved over 25 years. He will then speculate on the needs for scaling designs into solutions for 2020 from tiny embedded sensors through to cloud-based servers that together enable the “Internet of things.” Mike will look at the major challenges that need to be addressed to design and manufacture these systems and propose some solutions.

Wednesday, June 6, 2012 from 10:45am to 11:45am

Designing High Performance Systems-on-Chip

Joshua Friedrich, Senior Technical Staff Member and Senior Manager of POWERTM Technology Development in IBM’s Server and Technology Group. Brad Heaney, Intel Architecture Group Project Manager, Intel Corp., Folsom, CA.

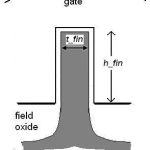

Experience state-of-the art design through the eyes of these two experts. Joshua Friedrich will talk about POWER processor design and methodology directions and Brad Heaney will discuss designing the latest Intel architecture multi-CPU and GPU. In this unique dual-keynote, the speakers will cover key challenges, engineering decisions and design methodologies to achieve top performance and turn-around time. The presentations describe where EDA meets practice under the most advanced nodes.

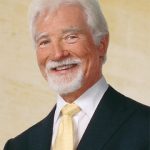

Thursday, June 7, 2012 from 11:00am to 12:00pm

My First Design Automation Conference – 1982

C. L. (Dave) Liu of Tsing Hua University and also the recipient of the 2012 Phil Kaufman award.

Dave tells us: “It was June 1982 that I had my first technical paper in the EDA area presented at the 19th Design Automation Conference. It was exactly 20 years after I completed my doctoral study and exactly 30 years ago from today. I would like to share with the audience how my prior educational experience prepared me to enter the EDA field and how my EDA experience prepared me for the other aspects of my professional life.”

I hope to see you all there!