As the Internet of Things (IoT) opportunities continues to expand, companies are working hard to bring System-on-Chip (SoC) solutions to market in the hopes of garnering market share and revenue. However, it’s not as easy as it may first seem. Companies are running into a series of issues that stand between them and capturing the market.

I had the chance to sit in on a panel session at the 54[SUP]th[/SUP] Design Automation Conference (DAC) that tried to address how companies can overcome these challenges. The panel was chaired by Ed Sperling of Semiconductor Engineering and was held at the Mentor booth on the DAC exhibit floor. On the panel were Mike Eftimakis from ARM, Jeff Miller from the Mentor Tanner group and John Tinson of Sondrel. Ed started off the discussion asking the panelists what they felt the main challenges were for IoT SoC designers.

I had the chance to sit in on a panel session at the 54[SUP]th[/SUP] Design Automation Conference (DAC) that tried to address how companies can overcome these challenges. The panel was chaired by Ed Sperling of Semiconductor Engineering and was held at the Mentor booth on the DAC exhibit floor. On the panel were Mike Eftimakis from ARM, Jeff Miller from the Mentor Tanner group and John Tinson of Sondrel. Ed started off the discussion asking the panelists what they felt the main challenges were for IoT SoC designers.

Mike Eftimakis responded that ARM sees three main challenges for SoCs targeted at IoT applications.

[LIST=1]

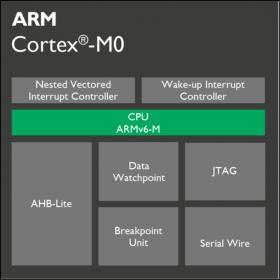

Mike sees ARM helping designers meet these challenges by offering simple processors for edge devices that can be manufactured in high volumes and low costs. Having one of these processors in the edge device gives the SoC designer the ability to enable customization for derivative markets while at the same time doing sensor fusion and some analysis to cut down on the required amount of data to be sent to the Cloud.

Mike sees ARM helping designers meet these challenges by offering simple processors for edge devices that can be manufactured in high volumes and low costs. Having one of these processors in the edge device gives the SoC designer the ability to enable customization for derivative markets while at the same time doing sensor fusion and some analysis to cut down on the required amount of data to be sent to the Cloud.

To be able to build these SoCs quickly and to be able to pivot with the changing IoT market, ARM also believes that having pre-verified design elements and subsystems will also enable designers to rapidly build prototypes that can be tested in the market. Also, by modularizing the SoC architecture, it would allow designers to quickly customize the same base SoC with different interfaces for different end applications.

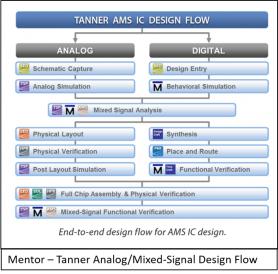

Jeff Miller of Mentor agreed with Mike’s assessment and suggested that another enabling technology is electronic design automation (EDA) software that can be used for analog and mixed signal designs. Jeff pointed out that almost all edge devices will be dealing with the real world which is in fact, analog. Edge devices will need to be able to integrate and possibly control analog signals while also analyzing and converting their data into digital representations that can easily be sent to the Cloud. Many of these devices will also be communicating to gateways using wireless technologies which means that the design and associated EDA tools will also need to comprehend RF technologies as well.

Jeff Miller of Mentor agreed with Mike’s assessment and suggested that another enabling technology is electronic design automation (EDA) software that can be used for analog and mixed signal designs. Jeff pointed out that almost all edge devices will be dealing with the real world which is in fact, analog. Edge devices will need to be able to integrate and possibly control analog signals while also analyzing and converting their data into digital representations that can easily be sent to the Cloud. Many of these devices will also be communicating to gateways using wireless technologies which means that the design and associated EDA tools will also need to comprehend RF technologies as well.

John Tinson of Sondrel pointed out that designing these types of SoC is a daunting task as it cuts across multiple engineering domains. While this might be manageable for some of the larger enterprise-level SoC providers, it is not so easy for cash strapped start-up companies. Time to market will be key for these companies and Sondrel’s mission is to help these types of companies by providing design services to reduce their time to market. Sondrel brings with it a significant amount of experience in putting together SoCs which can help to reduce and mitigate risks for start-up companies and their investors.

Ed Sperling pointed out that while pre-assembled and verified design blocks are useful, he wondered whether the IoT market is mature enough for designers to be able to know which blocks should be offered. He also questioned whether it was really feasible to reuse designs across such widely differing end use markets. Mike from ARM responded that they felt that there were definitely sub-segments to the IoT application space for which design reuse would certainly be possible and he made the point that indeed these would be the market segments that people should target to ensure they get a return on their investment. Jeff from Mentor agreed and pointed out that the key would be to start with a set of building blocks that were fundamental to all designs and then add more over time as more functions become integrated at the edge devices. A couple good example of these types of blocks would be security hardware for the edge devices and communications interfaces.

Mike from ARM also pointed out that because IoT is still not well defined, it makes a lot of sense to build flexibility into your SoC designs so that you can pivot with the market when needed. An example of this would be the requirement to be able to do over-the-air updates to the firmware of the edge devices.

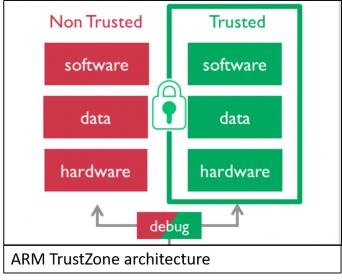

Ed Sperling brought the group around to another hot topic for all things IoT based and that was the question of security. Ed pointed out that the threat surface is continually changing and asked the question of how should companies deal with this challenge. Mike from ARM suggested that designers think about segregating their design domains to have a clean, water tight separation between the critical functions of the device (boot up, firmware memory, communications and control) and the applications side of the device. The Cortex-M processors from ARM with built-in TrustZone hardware helps designers do this when using ARM-based processors in their designs.

Ed Sperling brought the group around to another hot topic for all things IoT based and that was the question of security. Ed pointed out that the threat surface is continually changing and asked the question of how should companies deal with this challenge. Mike from ARM suggested that designers think about segregating their design domains to have a clean, water tight separation between the critical functions of the device (boot up, firmware memory, communications and control) and the applications side of the device. The Cortex-M processors from ARM with built-in TrustZone hardware helps designers do this when using ARM-based processors in their designs.

Jeff from Mentor agreed. He suggested what he called defense in depth, including making sure the design company is in control of the SoC as it moves through different stages of the ecosystem. Once the design has left your company to be fabricated, packaged and tested it can be vulnerable to hacking. Every stop along the way is a possible attack point and designers need to have test suites to ensure that the final packaged devices are not doing something that they were not intended to do. These kinds of checks must be engineered into the system before the SoC design is started.

All in all, this was an excellent panel session. A job well done goes out to Ed, Mike, Jeff and John who covered a lot of information in a short amount of time (a lot of which I wasn’t even able to capture in this short article). Double kudos go to Mentor for sponsoring the event.

See Also:

ARM TrustZone

Mentor/Tanner AMS Solution

Sondrel Design Services

Comments

There are no comments yet.

You must register or log in to view/post comments.