The resolution of EUV lithography is commonly expected to benefit from the shorter wavelengths (13.2-13.8 nm) but in actuality the printing process needs to include Pde the consideration of the lower energy electrons released by the absorption of EUV photons. The EUV photon energy itself has a nominal energy range of 90-94 eV,… Read More

Is ASML Immune from China Impact?

-ASML has great QTR & Outlook & Huge Euro8.9B orders

-Relatively immune from China due to mainly non leading edge

-Monster Euro38B backlog – 60EUV & 375DUV systems in 2023

-5% China risk to 2023- still mainly supply constrained

ASML proves litho’s place at Apex of semiconductor food chain

ASML announced… Read More

Where Are EUV Doses Headed?

In spite of increasing usage of EUV lithography, stochastic defects have not gone away. What’s becoming clearer is that EUV doses must be managed to minimize the impact from such defects. The 2022 edition of the International Roadmap for Devices and Systems has updated its Lithography portion [1]. An upward trend with decreasing… Read More

Application-Specific Lithography: 5nm Node Gate Patterning

It has recently been revealed that the N5 node from TSMC has a minimum gate pitch of 51 nm [1,2] with a channel length as small as 6 nm [2]. Such a tight channel length entails tight CD control in the patterning process, well under 0.5 nm. What are the possible lithography scenarios?

Blur Limitations for EUV Exposure

A state-of-the-art

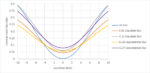

Spot Pairs for Measurement of Secondary Electron Blur in EUV and E-beam Resists

There is growing awareness that EUV lithography is actually an imaging technique that heavily depends on the distribution of secondary electrons in the resist layer [1-5]. The stochastic aspects should be traced not only to the discrete number of photons absorbed but also the electrons that are subsequently released. The electron… Read More

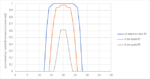

EUV’s Pupil Fill and Resist Limitations at 3nm

The 3nm node is projected to feature around a 22 nm metal pitch [1,2]. This poses some new challenges for the use of EUV lithography. Some challenges are different for the 0.33NA vs. 0.55NA systems.

0.33 NA

For 0.33 NA systems, 22 nm pitch can only be supported by illumination filling 4% of the pupil, well below the 20% lower limit for

ASML- US Seeks to Halt DUV China Sales

-If you can’t beat them, embargo them

-It has been reported US wants ASML to halt China DUV tools

-US obviously wants to kill, not just wound China chip biz

-Is this embargo the alternative to failed CHIPS act?

-Hard to say “do as I say, not as I do”- but US does anyway

First EUV ban now DUV ban? Are process & yield… Read More

ASML EUV Update at SPIE

At the 2022 SPIE Advanced Lithography Conference, ASML presented an update on EUV. I recently had a chance to go over the presentations with Mike Lercel of ASML. The following is a summary of our discussions.

0.33 NA

The 0.33 NA EUV systems are the production workhorse systems for leading edge lithography today. 0.33 NA systems are… Read More

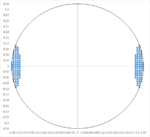

Obscuration-Induced Pitch Incompatibilities in High-NA EUV Lithography

The next generation of EUV lithography systems are based on a numerical aperture (NA) of 0.55, a 67% increase from the current value of 0.33. It targets being able to print 16 nm pitch [1]. The High-NA systems are already expected to face complications from four issues: (1) reduced depth-of-focus requires thinner resists, which… Read More

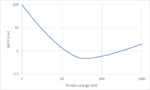

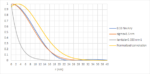

The Electron Spread Function in EUV Lithography

To the general public, EUV lithography’s resolution can be traced back to its short wavelengths (13.2-13.8 nm), but the true printed resolution has always been affected by the stochastic behavior of the electrons released by EUV absorption [1-5].

A 0.33 NA EUV system is expected to have a diffraction-limited point spread… Read More

The Risk of Not Optimizing Clock Power