Blogging is not an easy thing to do. It takes time, patience, commitment, and creativity. SemiWiki brought blogging to the semiconductor industry and many companies have followed. Very few have been successful with personal or corporate blogs but as a premier semiconductor blogger I have developed a proven recipe over the last ten years and can spot a winner when I see one.

As a corporate blog success story I will point to the Achronix blog site. Over the last three years Achronix has posted 28 blogs. My preference would be one per month without fail but 28 in 37 months is a serious commitment. There is a nice mix of authors from different aspects of the company (engineering, marketing, applications, C level, etc…):

– Kent Orthner, Systems Architect

– Alok Sanghavi, Sr. Marketing Manager

– Steve Mensor, Vice President, Marketing

– Katie Purcell, Senior Staff Applications Engineer

– Volkan Oktem, Sr. Director of Application

– Manoj Roge, VP of Strategic Planning & Business Development

– Raymond Nijssen, Vice President and Chief Technologist

– Bob SIller, Director, Product Marketing

– Huang Lun, Sr. Field Applications Engineer

While Author is important, blog title and the first paragraph is everything for both direct and search traffic. You need to speak to a specific problem to get high quality traffic. For semiconductor sites, quality versus quantity is important and be very careful about clickbait because it is a double edged sword. Again, the Achronix blogs are a great example for titles and summaries:

Embedded FPGAs for Next-Generation Automotive ASICs

Bob SIller, Sr. Marketing Manager

For anyone who has looked at new cars lately, it’s hard not to notice how quickly automotive electronics are advancing. Looking at automotive safety technology from just three years ago vs. today, you see a significant increase in the number of cameras to support applications such as surround-view display, driver distraction monitors, stereo vision cameras, forward-facing and multiple rearview cameras. Speedcore

Increase Performance Using an FPGA with 2D NoC

Huang Lun, Sr. Field Applications Engineer

Achronix Speedster7t FPGAs feature a revolutionary new two-dimensional network on chip (NoC), which provides >20 Tbps ultra-high bandwidth connectivity to external high-speed interfaces and for routing data within the programmable logic fabric. The NoC is structured as a series of rows and columns spread across the Speedster7t FPGA fabric. Each row or column has two 256-bit data paths using industry standard AXI data format, which support 512 Gbps data rates.

What is an FPGA and Why the Answer is Changing?

Bob Siller, Director, Product Marketing

What is an FPGA? With the advent of new FPGA architectures, the answer has changed more in the last two years than ever before. Traditionally, an FPGA or field programmable gate array, is a reconfigurable semiconductor device comprising programmable logic gates and interconnect or routing, connected to multipurpose I/O pins. An FPGA can be reprogrammed to perform any function, and its functionality can be changed over time. (For a great summary and history of the FPGA industry and technology.

Insights from the Next FPGA Platform Event

Manoj Roge, VP of Strategic Planning & Business Development

It was exciting to participate in Next FPGA Platform on January 22nd at the Glasshouse in San Jose. I found it was particularly exciting to have Achronix share in a panel discussion with Xilinx and Intel. The Next Platform co-editors Nicole Hemsoth and Timothy Prickett Morgan did a great job in interviewing experts from FPGA ecosystem with insightful questions. The best part of Next Platform events is their format, where they keep marketing pitches to minimum with no presentations, just discussions.

FPGAs in the 2020s – The New Old Thing

Bob Siller, Director, Product Marketing

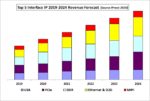

FPGAs are the new old thing in semiconductors today. Even though FPGAs are 35 years old, the next decade represents a growth opportunity that hasn’t been seen since the early 1990s. Why is this happening now?

Mine Cryptocurrencies Sooner Part 1-3

Raymond Nijssen, Vice President, Marketing

Cryptocurrency mining is the process of computing a new cryptocurrency unit based on all the previously found ones. The concept of cryptocurrency is nearly universally recognized by the publicity of the original cryptocurrency, Bitcoin. Cryptocurrencies were supposed to be a broadly democratic currency vehicle not controlled by any one entity, such as banks, governments, or small groups of companies. Much of a cryptocurrency’s acceptance and trustworthiness is based on that proposition. However, with Bitcoin, that is not how it unfolded.

Getting the first wave of blog views is actually the easy part. Keeping readership is critical and that is all about the quality of content. If I had to credit one thing for the success of SemiWiki over the last 10 years it would be excellent content. All content on a company website is important but done correctly blogs can bring a consistent stream of high quality traffic and improve your website SEO and rankings, absolutely.

You should also check out the Achronix videos and webinars, very well done!

About Achronix Semiconductor Corporation

Achronix Semiconductor Corporation is a privately held, fabless semiconductor corporation based in Santa Clara, California and offers high-performance FPGA and embedded FPGA (eFPGA) solutions. Achronix’s history is one of pushing the boundaries in the high-performance FPGA market. Achronix offerings include programmable FPGA fabrics, discrete high-performance and high-density FPGAs with hardwired system-level blocks, datacenter and HPC hardware accelerator boards, and best-in-class EDA software supporting all Achronix products. The company has sales offices and representatives in the United States, Europe, and China, and has a research and design office in Bangalore, India..

Follow Achronix

Website: www.achronix.com

The Achronix Blog: /blogs/

Twitter: @AchronixInc

LinkedIn: https://www.linkedin.com/company/57668/

Facebook: https://www.facebook.com/achronix/