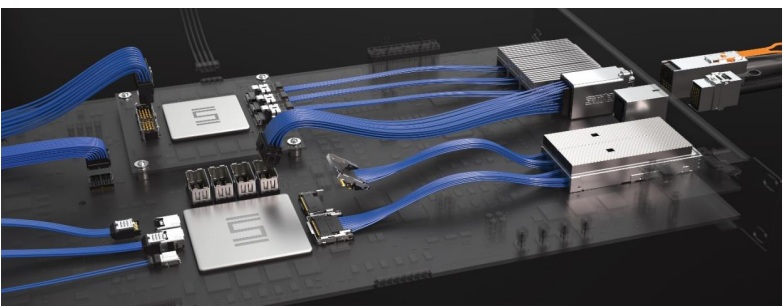

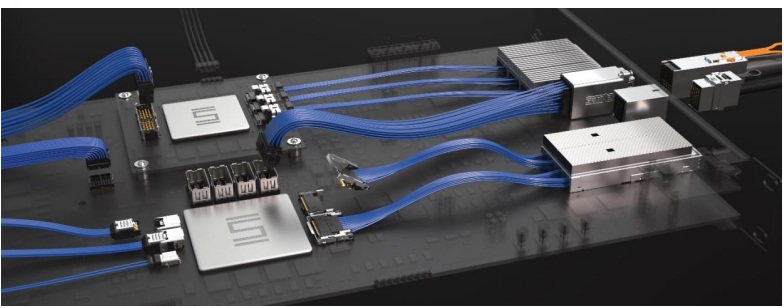

According to a recent Samtec whitepaper, in high-data-rate (HDR) architectures, where signals traverse tens to hundreds of gigabits per second, “cable management” isn’t a housekeeping chore, it’s a first-order design variable. The mechanical path a cable takes directly influences channel loss, crosstalk, reliability, rework costs, and even thermal performance. The most successful programs treat cable routing, bend strategy, strain relief, and labeling as part of early architecture, co-optimizing them alongside signal integrity (SI), thermals, and assembly. That mindset unlocks cleaner channels, faster bring-up, and fewer surprises in environmental or HALT testing.

Bend control is foundational. Every cable has a static minimum bend radius below which impedance discontinuities, jacket damage, or conductor fatigue become likely. Minimums vary with construction and gauge; designers should consult product-specific data rather than assume generic rules. As one illustrative datum, 34-AWG twinax/coax commonly specifies a 3.1 mm (0.125″) minimum bend radius—tight by eye, but still large enough to demand discipline in dense layouts. Two practical rules follow: avoid bunching (it effectively increases the required minimum), and allow cables to splay as they leave the connector so the first bend is gentle and not levering the termination. When routing along the connector’s length, the best practice is “bend, then twist”: first introduce the desired bend, then apply a controlled 90° twist over ~1.5″ to re-orient the exit without over-stressing the bundle.

Sleeving is valuable when used judiciously. Its role is protective—guarding jackets from nicks, abrasion, and errant edges—while offering light organizational benefits in cable-rich builds. Oversized, stretchable sleeves are preferred because they let strands splay naturally at bends and turns; tight sleeves (or large labels placed on them) add stiffness right where compliance is needed. Keep sleeves away from tight-radius regions, and use edge tape only where necessary. Strain is the other half of the story: always design for slack. Select lengths to accommodate both the final mated condition and the act of insertion/removal, short cables (<10 in / 25 cm) are especially sensitive. Where slack cannot be guaranteed, consult qualification data on allowable normal and side loads and, if needed, transfer load paths from the connector into the chassis or PCB via brackets or tie-downs. If compressive forces are unavoidable, preserve degrees of freedom so cables can splay and dissipate stress rather than prying at the interface.

Labeling and identification deserve more attention than they usually get. In production, field service, and RMA workflows, smart labels pay for themselves, yet they can become unintended stiffeners if applied indiscriminately. Keep labels minimal, place them on individual strands rather than wrapped around a bundle, and keep them clear of bend zones. Color coding can accelerate assembly while reducing handling time (and the handling damage that comes with it). Surround these mechanical practices with a robust set of enablement tools: full-channel SI models and evaluation kits for pre-layout what-ifs; thermal analysis to compute pressure drops and airflow interaction in cabled systems; and physical mock-ups to validate touch-labor ergonomics before freezing the design. Mature vendors also offer application-engineering support, custom sleeves and labels, and solution finders that map needs to qualified assemblies, particularly relevant for mid-board, front-panel, backplane, and Flyover® use cases.

In sum, HDR cable management is about treating the cable path as part of the channel, not an afterthought to be “neatened up” at the end. Respect bend radius by design; route to avoid bunching and leverage bend-then-twist to re-orient without stress; use sleeves for protection, not constriction; preserve slack and manage loads into structures that can bear them; label intelligently without adding stiffness; and anchor the whole effort with SI, thermal, and assembly analyses up front. Do these things, and you’ll ship systems that are faster to validate, more robust in the field, and easier to service—outcomes that matter just as much as the headline data rate.

Read the full Samtec white paper here

Also Read:

How Channel Operating Margin (COM) Came to be and Why It Endures

Visualizing System Design with Samtec’s Picture Search

Webinar – Achieving Seamless 1.6 Tbps Interoperability with Samtec and Synopsys

Comments

There are no comments yet.

You must register or log in to view/post comments.