The existence of TSMC’s Open Innovation Platform (OIP) program further sped up disaggregation of the semiconductor supply chain. Partly, this was enabled by the existence of a healthy EDA industry and an increasingly healthy IP industry. As chip designs had grown more complex and entered the system-on-chip (SoC) era, the amount of IP on each chip was beyond the capability or the desire of each design group to create. But, especially in a new process, EDA and IP qualification was a problem.

See also Part 1.

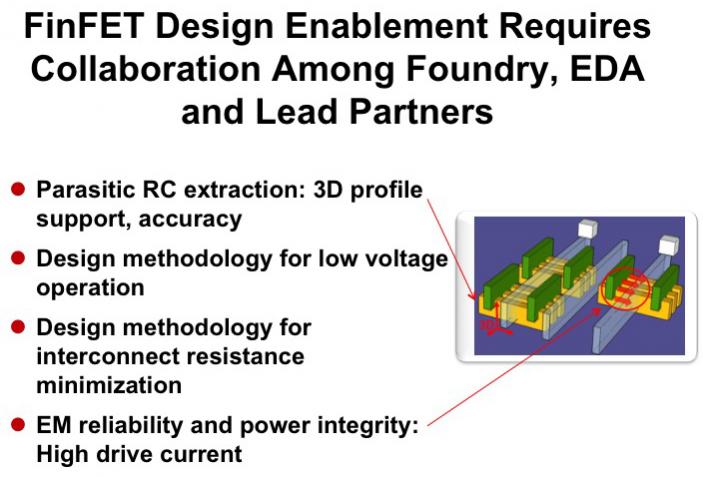

On the EDA side, each new process came with some new discontinuous requirements that required more than just expanding the capacity and speed of the tools to keep up with increasing design size. Strained silicon, high-K metal gate, double patterning and FinFETs each require new support in the tools and designs to drive the development and test of the innovative technology.

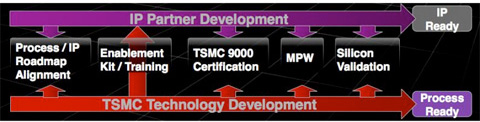

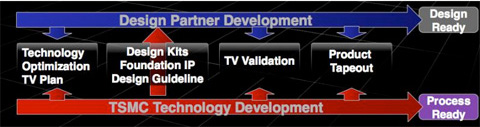

On the IP side, design groups increasingly wanted to focus all their efforts on parts of their chip that differentiated them from their competition, and not on re-designing standard interfaces. But that meant that IP companies needed to create the standard interfaces and have them validated in silicon much earlier than before.

The result of OIP has been to create an ecosystem of EDA and IP companies, along with TSMC’s manufacturing, to speed up innovation everywhere. Because EDA and IP groups need to start work before everything about the process is ready and stable, the OIP ecosystem requires a high level of cooperation and trust.

When TSMC was founded in 1987, it really created two industries. The first, obviously, is the foundry industry that TSMC pioneered before others entered. The second was the fabless semiconductor companies that do not need to invest in fabs. This has been so successful that two of the top 10 semiconductor companies, Qualcomm and Broadcom, are fabless. And all the top FPGA companies are fabless.

The foundry/fabless model largely replaced IDMs and ASIC. An ecosystem of co-operating specialist companies innovates fast. The old model of having process, design tools and IP all integrated under one roof has largely disappeared, along with the “not invented here” syndrome that slowed progress since ideas from outside the IDMs had a tough time penetrating. Even some of the earliest IDMs from the “real men have fabs” era have gone “fab lite” and use foundries for some of their capacity, typically at the most advanced nodes.

Legendary TSMC Chairman Morris Chang’s “Grand Alliance” is a business model innovation of which OIP is an important part, gathering all the significant players together to support customers. Not just EDA and IP but also equipment and materials suppliers, especially high-end lithography.

Digging down another level into OIP, there are several important components that allow TSMC to coordinate the design ecosystem for their customers.

EDA: the commercial design tool business flourished when designs got too large for hand-crafted approaches and most semiconductor companies realized they did not have the expertise or resources in-house to develop all their own tools. This was driven more strongly in the front-end with the invention of ASIC, especially gate-arrays; and then in the back end with the invention of foundries.

EDA: the commercial design tool business flourished when designs got too large for hand-crafted approaches and most semiconductor companies realized they did not have the expertise or resources in-house to develop all their own tools. This was driven more strongly in the front-end with the invention of ASIC, especially gate-arrays; and then in the back end with the invention of foundries.

IP: this used to be a niche business with a mixed reputation, but now is very important with companies like ARM, Imagination, CEVA, Cadence andSynopsys, all carrying portfolios of important IP such as microprocessors, DDRx, Ethernet, flash memory and so on. In fact, large SoCs now contain over 50% and sometimes as much as 80% IP. TSMC has well over 5,500 qualified IP blocks for customers.

IP: this used to be a niche business with a mixed reputation, but now is very important with companies like ARM, Imagination, CEVA, Cadence andSynopsys, all carrying portfolios of important IP such as microprocessors, DDRx, Ethernet, flash memory and so on. In fact, large SoCs now contain over 50% and sometimes as much as 80% IP. TSMC has well over 5,500 qualified IP blocks for customers.

Services: design services and other value-chain services calibrated with TSMC process technology helps customers maximize efficiency and profit, getting designs into high volume production rapidly

Services: design services and other value-chain services calibrated with TSMC process technology helps customers maximize efficiency and profit, getting designs into high volume production rapidly

- Investment: TSMC and its customers invest over $12B/year. TSMC and its OIP partners alone invest over $1.5B. On advanced lithography, TSMC has further invested $1.3B in ASML.

Processes are continuing to get more advanced and complex, and the size of a fab that is economical also continues to increase. This means that collaboration needs to increase as the only way to both keep costs in check and ensure that all the pieces required for a successful design are ready just when they are needed.

TSMC has been building ecosystems of increasing richness for over 25 years and feedback from partners is that they see benefits sooner and more consistently than when dealing with other foundries. Success comes from integrating usage, business models, technology and the OIP ecosystem so that everyone succeeds. There are a lot of moving parts that all have to be ready. It is not possible to design a modern SoC without design tools, more and more SoCs involve more and more 3[SUP]rd[/SUP] party IP, and, at the heart of it all, the process and the manufacturing ramp with its associated yield learning all needs to be in place at TSMC.

The proof is in the numbers. Fabless growth in 2013 is forecasted to be 9%, over twice the increase for the overall industry at 4%. Fabless has doubled in size as a percentage of the semiconductor market from 8% to 16%, during a period when the growth in the overall semiconductor market has been unimpressive. TSMC’s own contribution to semiconductor revenue grew from 10% to 17% over the same period.

The OIP ecosystem has been a key pillar in enabling this sea change in the semiconductor industry.

TSMC’s OIP Symposium is October 1st. Details and to register here.

Comments

0 Replies to “A Brief History of TSMC’s OIP part 2”

You must register or log in to view/post comments.