While stochastic defects link yield with the practical resolution of EUV lithography resulting from its quantum nature [1], very low yields of EUV processes are more readily linked to the use of EUV masks without pellicles. Pellicles are thin film membrane covers on masks (regardless of wavelength: EUV and DUV and i-line) used to protect from particles landing on the patterns on the mask. Particles could land on the pellicle, but they would not print because they would be so out of focus. Without pellicles, yield can drop significantly just from having a few particles land on the mask [2].

Surprisingly, it has been reported recently that EUV users generally do not use pellicles [3,4]. The key reason is that pellicles can be damaged or even ruptured due to EUV light exposure [5]. TSMC also reported in 2023 that its EUV pellicle infrastructure was just completed, but still not yet in production [6]. They also noted that “with the increase in scanner power to 400W, a pellicle lifetime challenge has been observed” [6]. Moreover, it has been reported this year that TSMC was reluctant to use EUV pellicles since they need to be replaced every 3–4 days, at a high cost of over $10000 each [4].

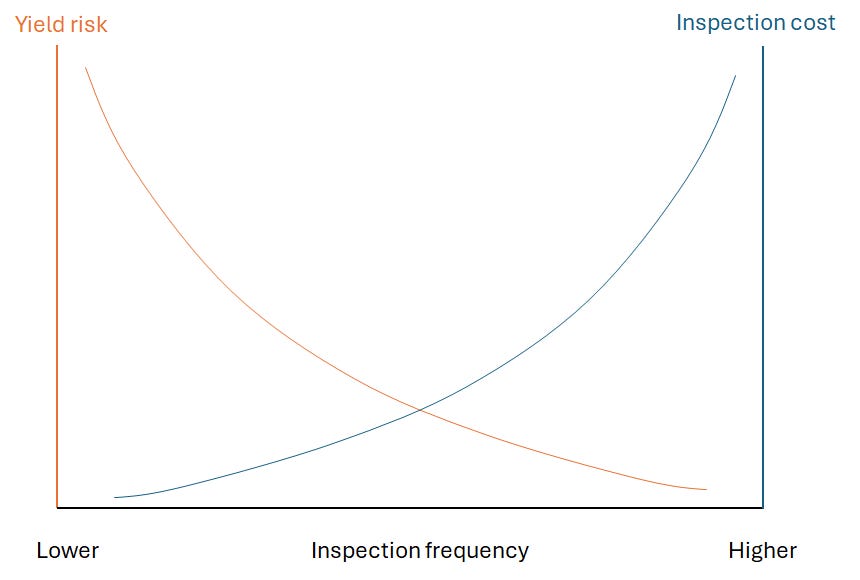

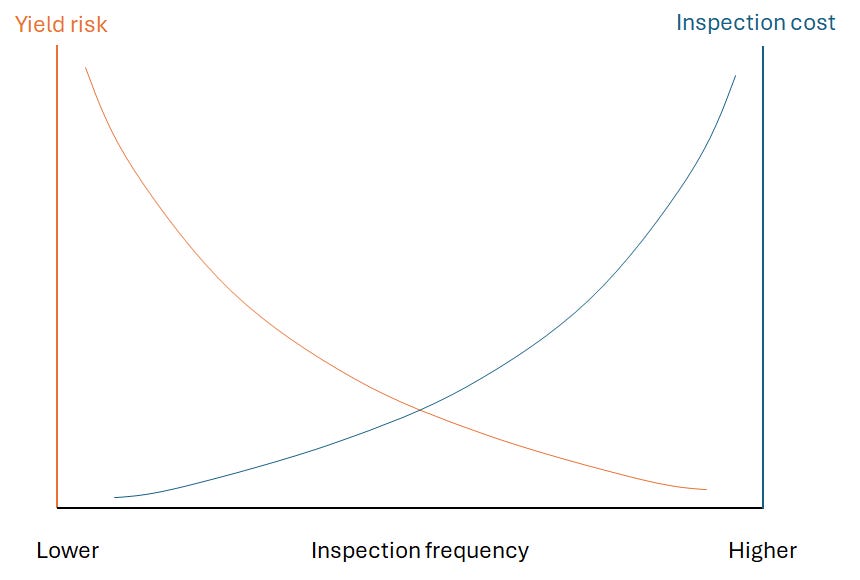

Without the use of pellicles, it has been necessary to periodically check if particles had attached to the mask in the pattern area [7]. Note that increased inspection frequency means fewer output wafers per month. This leads to a tradeoff between inspection cost and yield risk (Figure 1).

The struggle for yield without pellicles is in line with continuing reports of yields less than 70% [8,9]. Nevertheless, even this year, Samsung reported ongoing concerns with EUV pellicle lifetimes, even with more promising candidate materials [10]. EUV users concerned about yield will need to continue to focus on particle contamination control.

References

[1] F. Chen, IMEC’s Advanced Node Yield Model Now Addresses EUV Stochastics; Facing the Quantum Nature of EUV Lithography.

[2] F. Chen, Explaining Pellicle-Free EUV Yield Loss.

[3] TheElec, FST in talks with Samsung to supply EUV pellicle, Sept. 3, 2025.

[4] Global Technology Research, Carbon Nanotube (CNT)- The Next Big Thing for EUV Pellicle?, Jan. 14, 2025.

[5] US Patent 10976674, assigned to TSMC.

[6] Y-Y. Lin et al., Proc. SPIE 12750, 127500N (2023).

[7] M. van de Kerkhof et al., Proc. SPIE 10957, 109570U (2019).

[8] TechPowerUp, Samsung’s Second-Gen 3 nm GAA Process Shows 20% Yields, Missing Production Goals, Nov. 11, 2024.

[9] TrendForce, [News] Intel 18A Yield Reportedly Just 10% at Risk Production, Casting Doubt on Panther Lake Plans, Aug. 6, 2025.

[10] M. J. Kim et al., Proc. SPIE 13424, 1342405 (2025).

Also Read:

TSMC Repurposing Old Fabs to Bring EUV Pellicle Production In-House

EUV Resist Degradation with Outgassing at Higher Doses

IMEC’s Advanced Node Yield Model Now Addresses EUV Stochastics

Edge Roughness Differences Among EUV Resists

Share this post via:

A Century of Miracles: From the FET’s Inception to the Horizons Ahead