In previous articles, I had looked at EUV stochastic behavior [1-2], primarily in terms of the low photon density resulting in shot noise, described by the Poisson distribution [3]. The role of blur to help combat the randomness of EUV photon absorption and secondary electron generation and migration was also recently considered [4-5]. However, up to now, blur resulting from electron and chemical species migrations had been given the classical continuum treatment, when in actuality, at the nanometer scale, we are again dealing with random numbers of discrete quanta, i.e., electrons or chemically reactive species. These discrete quanta still follow Poisson distributions [6]. So, it is necessary to have a stochastic reconsideration after blur has already been taken into account.

This reconsideration seems necessary after the latest results at 28 nm pitch were were reported at SPIE earlier this year [7]. In order to achieve better imaging, metal oxide resists were used. These have the benefit of higher EUV photon absorption, which should provide relief for stochastic behavior. Despite this advantage, stochastic aspects of the imaging remained severe. Higher doses in the range of 50 mJ/cm2 (~110 WPH on the NXE:3400C [8]) were required, but larger CDs or dummy subresolution assist features (SRAFs) were needed for larger pitches. With optimized illumination, printing a relatively isolated pair of 14 nm trenches separated by 14 nm (local 28 nm pitch) was impossible without stochastic defects and roughness. Therefore, the reconsideration of post-blur stochastic effects here will focus on 28 nm pitch.

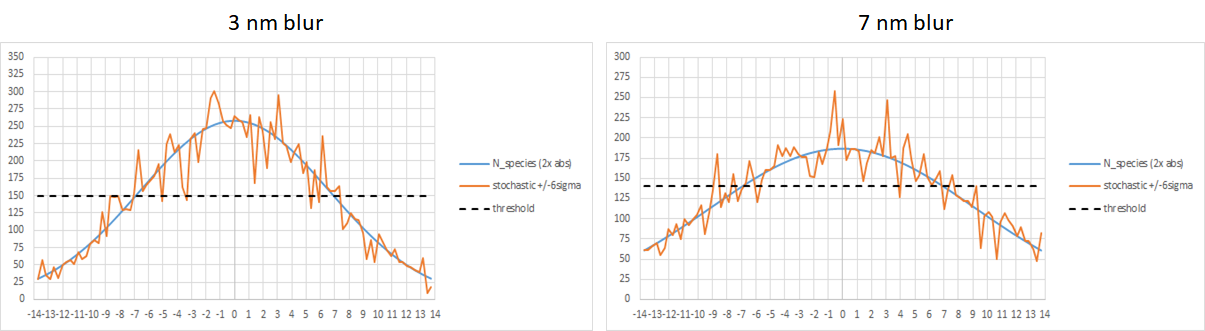

Blur is practically limited to less than 5 nm (sigma) for 40 nm pitches or less [5]. Increasing blur would result in the distribution of quanta becoming flatter, and a generally worse image. There is a larger risk of stochastic fluctuations further from the edge (Figure 1).

Figure 1. Reactive species number distribution plotted vs. position. The species number is considered within a 0.84 nm x 5 nm strip, assuming 50 mJ/cm2 incident dose, 50% absorption, and 2 species released per absorbed photon. Left: 3 nm blur. Right: 7 nm blur.

A new consideration is the quantum yield (or quantum efficiency), i.e., how many quanta are released per absorbed photon. Quantum efficiency for EUV chemically amplified resists is around 2 [9,10]. To reduce blur to 2 nm or less, it is expected to limit this release, in order to avoid excess random secondary electron and reactive species migration [9]. In Figure 2, a 2X reduction in quantum yield for 2nm blur (compared to 3 nm blur) shows the risk of stochastic defects does not improve and could get worse. It should be no big surprise, as quantum yield reduction has the same final effect as reducing photon density. In all these cases, we see fluctuations that cross the threshold, which means both line bridging and line breaking defects are possible. Six sigma corresponds to ~1 ppb failure.

Figure 2. Reactive species number distribution plotted vs. position. The species number is considered within a 0.84 nm x 5 nm strip, assuming 50 mJ/cm2 incident dose, 50% absorption. Left: 2 nm blur, 1 species released per absorbed photon. Right: 3 nm blur, 2 species released per absorbed photon.

Moreover, line edge roughness can be studied by reducing the line section length being sampled. Going from 5 nm to 1 nm section length, even 3 sigma fluctuations cross the threshold (Figure 3), indicating that roughness on the 1 nm scale is still present.

Figure 3. Reactive species number distribution plotted vs. position. The species number is considered within a 0.84 nm x 1 nm strip, assuming 50 mJ/cm2 incident dose, 50% absorption. 3 nm blur is assumed.

The only manageable solution to these issues remains to increase the dose (Figure 4). Given that there is already a throughput hit at 50 mJ/cm2, EUV source power will continue to be a priority target. However, higher doses could lead to larger blur due to the long tail detected in electron attenuation length measurements [11,12].

Figure 4. Reactive species number distribution plotted vs. position. The species number is considered within a 0.84 nm x 5 nm strip, assuming 50% absorption, and 2 species released per absorbed photon. Left: 50 mJ/cm2 incident dose. Right: 100 mJ/cm2 incident dose. 3 nm blur is assumed.

References

[1] https://www.linkedin.com/pulse/euvs-stochastic-valley-death-frederick-chen/

[2] https://www.linkedin.com/pulse/photon-shot-noise-impact-line-end-placement-frederick-chen/

[3] https://en.wikipedia.org/wiki/Shot_noise

[4] https://www.linkedin.com/pulse/contrast-reduction-vs-photon-noise-euv-lithography-frederick-chen/

[5] https://www.linkedin.com/pulse/blur-wavelength-determines-resolution-advanced-nodes-frederick-chen/

[6] G. M. Gallatin, “Resist Blur and Line Edge Roughness,” Proc. SPIE 5754, 38 (2005).

[7] D. Xu et al., “EUV Single Patterning Exploration for Pitch 28 nm,” Proc. SPIE 11614, 116140Q (2021).

[8] https://www.linkedin.com/pulse/challenge-working-euv-doses-frederick-chen/

[9] http://euvlsymposium.lbl.gov/pdf/2007/RE-08-Gallatin.pdf

[10] https://www.jstage.jst.go.jp/article/photopolymer/32/1/32_161/_pdf

[11] https://escholarship.org/content/qt4t5908f6/qt4t5908f6.pdf?t=qd3uq5

[12] https://www.euvlitho.com/2019/P66.pdf

Share this post via:

CEO Interview with Aftkhar Aslam of yieldWerx