In an era defined by complex chip architectures, ever-shrinking technology nodes and very demanding applications, Silicon Lifecycle Management (SLM) has become a foundational strategy for optimizing performance, reliability, and efficiency across the lifespan of a semiconductor device. Central to effective SLM are Process, Voltage, and Temperature (PVT) monitors—silicon-proven, highly accurate sensors embedded into chips to provide real-time, in-silicon visibility. As devices grow in complexity and adopt technologies like 2.5D/3D IC packaging, GAA (Gate-All-Around), and BSP (Backside Power), traditional design-time assumptions and margining techniques are no longer sufficient. PVT monitoring is now indispensable for ensuring that chips operate efficiently, safely, and predictably under real-world conditions.

At the recent IPSoC Conference in Silicon Valley, Rohan Bhatnagar gave a talk on the growing importance of PVT Monitoring for effective SLM. Rohan is the product manager for Synopsys’s SLM PVT Monitor IPs. A synthesis of the salient points from his talk follows.

The Four Pillars of SLM

SLM is built on four core pillars: Monitor, Transport, Analyze, and Act. The process begins with embedding monitors during the chip design phase. These monitors collect critical data about process variation, voltage fluctuations, and thermal behavior. Next, this data is transported to a centralized SLM database, where it is analyzed either on-chip, on-edge or in-cloud. In the design phase, engineers can act on these real silicon insights from test silicon to fine tune their designs. During in-field operation, automated response routines are enabled in real-time to fine-tune performance, reduce power, and extend reliability/device longevity. This continuous loop of visibility and action forms the backbone of modern chip lifecycle optimization.

Why Real-Time Monitoring Is Essential

The motivation for adopting PVT monitors stems from the growing need to maximize performance and energy efficiency while extending reliability. Today’s semiconductor devices face significant challenges: large die areas introduce more spatial process variation, high-performance workloads lead to thermal hotspots and voltage droops, and modern packaging technologies introduce thermal and electrical complexity. Additionally, unpredictable application workloads make static margining approaches inadequate. PVT monitors allow for real-time tracking and response to these variables, enabling more intelligent decisions throughout the chip’s life, from silicon bring-up to field deployment.

Synopsys’ Comprehensive PVT IP Subsystem

The company’s PVT IP subsystem includes a full suite of monitors, a dedicated central controller and supporting infrastructure. Key components include the Process Detector (PD), Voltage Monitor (VM), and Glitch Detectors (GD, Digital GD). For thermal monitoring, the subsystem features a range of sensors such as the Temperature Sensor (TS), Distributed Temperature Sensor (DTS and Digital DTS), Catastrophic Temperature Sensor (CTS), and Thermal Diode (TD). With the exception of the Thermal Diode and the CTS that are asynchronous, the other sensors are managed by a central PVT Controller with software driver and interfaced via dedicated software serial buses.

The PVT IPs are validated on a broad spectrum of foundries and process nodes, ensuring future-ready compatibility. Recent support includes TSMC nodes such as N6, N5A, N4P, N3E/P, N3A, and N2P. In-development support includes Intel Foundry Services (IFS) 18A and Samsung SF4X. As the IP portfolio continues to grow, new offerings such as Digital DTS1 and Digital Glitch Detectors provide enhanced digital compatibility and lower integration overhead.

Synopsys’ PVT IP solutions are also tailored for automotive-grade applications, where reliability and safety are paramount. The hard IP is tested to AEC-Q100 Grade 2, while soft IP components are ISO 26262 ASIL B ready for functional safety compliance.

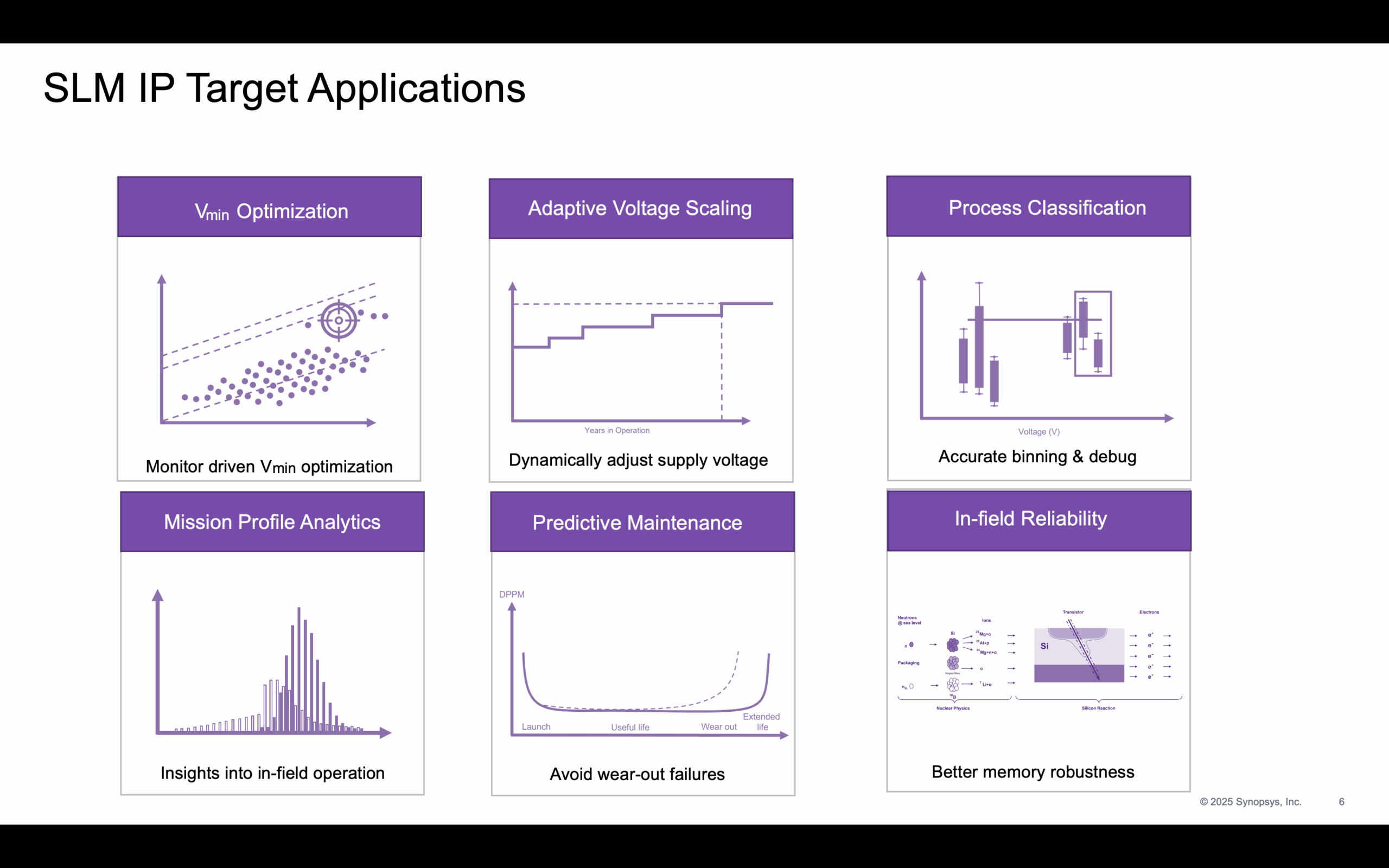

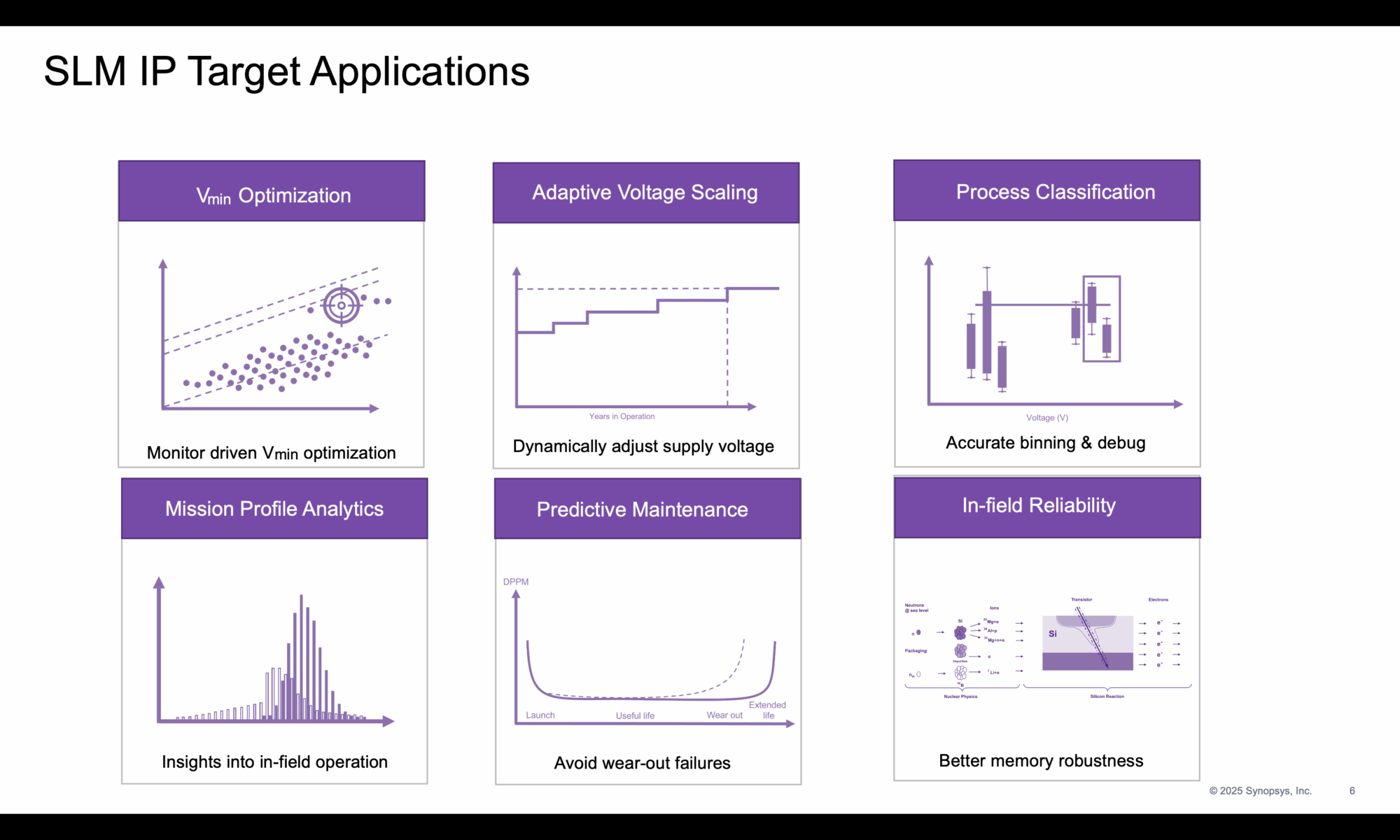

Use Cases for PVT IP Solutions

AI Processors

In AI SoCs, thermal and power challenges are significant due to high compute density and bursty workloads. PVT monitors enable low-latency thermal management, dynamic IR drop control, and supply margin optimization for critical logic. This results in improved core utilization, higher performance-per-watt, and reduced operational expenses.

Data Centers and HPC

In cloud and high-performance computing environments, reliability and power efficiency are vital. Embedded monitors support real-time power optimization, multi-core thermal analysis, and predictive reliability, helping data centers scale confidently while reducing CO₂ emissions and lowering total cost of ownership (TCO).

5G and Consumer Devices

For 5G smartphones and consumer electronics, PVT monitors address thermal challenges and enhance battery efficiency. They enable core voltage scaling, real-time thermal management, and performance tuning to improve user experiences in scenarios like video streaming, gaming, and multitasking. These optimizations also contribute to longer battery life and more responsive devices.

Summary

As semiconductor designs become more customized and operate in increasingly unpredictable environments, real-time in-silicon visibility is essential. The integration of SLM and PVT IP transforms chip design and lifecycle management into a dynamic, intelligent, and adaptive process. From development through deployment, SLM empowers engineers to make data-driven decisions that enhance performance, reduce power, and increase reliability.

Whether optimizing AI processors, powering hyperscale data centers, or enhancing mobile user experiences, SLM with PVT IP is enabling the next era of smart, efficient, and resilient semiconductor design. PVT monitors offer a scalable path forward for future-ready silicon.

Learn more about Synopsys SLM PVT Monitor IP Solutions here.

Also Read:

SNUG 2025: A Watershed Moment for EDA – Part 1

Synopsys Webinar: The Importance of Security in Multi-Die Designs – Navigating the Complex Landscape

Share this post via:

Comments

There are no comments yet.

You must register or log in to view/post comments.