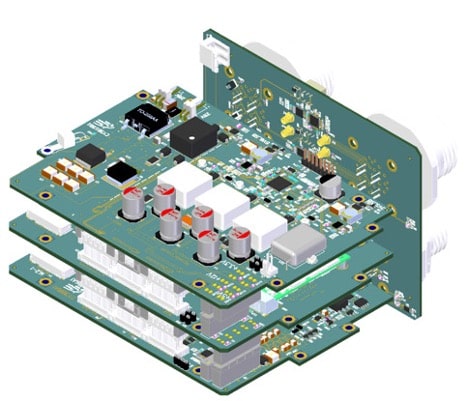

I knew that HDMI was a popular standard used to connect consumer products like a monitor to a laptop, but most professional video and broadcast systems use the SDI (Serial Digital Interface) connector standard. Pleora Technologies, founded in 2000, currently serves the machine vision and manufacturing markets, including those for military and security high-reliability applications built upon AI and machine vision automation products. One of these is the RuggedCONNECT Smart Video Switcher, used for video capture, processing, streaming, and display. This switcher supports RS-170/NTSC/PAL or 2 HD-SDI video inputs, plus two independent HD-SDI single link displays. Customers require products from Pleora that meet their unique size, energy, and bandwidth requirements.

This blog follows how Pleora got their smart switch to market using EDA tools from Siemens EDA. For video connectivity products the requirement is to network multi-vendor cameras, displays, processors and sensors using standards. Gigabit Ethernet was used in their video switcher, along with GPU and software to enhance video with AI and computer vision processing, enabling situational awareness and ADAS features.

In the case of the RuggedCONNECT Smart Video Switcher, military requirements meant that its boards had to be 1275 certified, as 28V vehicle batteries have to function with voltage spikes up to 250V in magnitude, while remaining quiet to meet rugged emission standards.

EDA Tools

Robert Turzo, Principal Hardware designer at Pleora used the Xpedition Enterprise and HyperLynx tools for the smart switch product design. Critical PCB signals were listed in the constraint manager, plus the DRC feature was used in Xpedition Layout to mitigate issues. They had 13 boards for their system design, and for design reuse they would clone part of an original design to seed the other designs. The seven different via types were stored in a central library with Xpedition, for easy sharing.

Automation performed the matching of the DDR3 and DDR4 interface, instead of manual efforts to meet specifications more quickly. The sketch router feature allowed human-guided auto-routing for multiple nets at a time, saving time and enabled meeting their schedule.

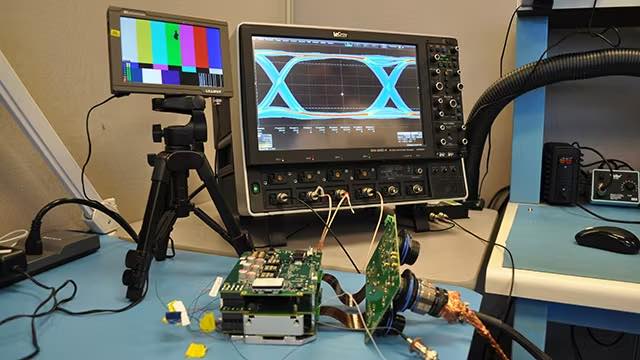

The smart switcher boards had four stack-ups for their rigid PC, and the fifth stack-up for a rigid-flex PCB. Each impedance-controlled trace was verified on the boards by running the HyperLynx tool. SI/PI (Signal Integrity, Power Integrity) analysis also was performed with HyperLynx in both front-end and back-end of the design process. Only one revision board was required prior to production. Simulation results performed during design did match the measurements after fabrication, so all that design analysis paid off. Thermal analysis with the Siemens Simcenter Flotherm tool was made easier by using PCB thermal data from HyperLynx.

Summary

Pleora was successful in their PCB design flow by using Xpedition and HyperLynx software tools on a project with buried vias, stacked micro vias and rigid-flex boards. SI/PI goals were met through analysis in HyperLynx. At the 29th annual Siemens Xcelerator Technology Innovation Awards, Pleora won 1st pace in the multi-board systems category. Read the complete case study online.

Related Blogs

- DDR5 Design Approach with Clocked Receivers

- A Complete Guidebook for PCB Design Automation

- Cracking post-route Compliance Checking for High-Speed Serial Links with HyperLynx

- EDA in the Cloud with Siemens EDA at #59DAC

- The Design Lifecycle of an Electronics Interface

- From Silicon To Systems

Comments

There are no comments yet.

You must register or log in to view/post comments.