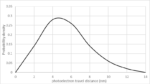

Conventionally, the resolution limit of a lithography system with wavelength l and numerical aperture NA is given by half-pitch = 0.25 wavelength/NA. With the use of EUV lithography, however, electron blur needs to be added [1]. The impact of this blur is to reduce the contrast [2]. Blur reduces the modulation amplitude by a factor… Read More

Can LELE Multipatterning Help Against EUV Stochastics?

Previously, I had indicated how detrimental stochastic effects at pitches below 50 nm should lead to reconsidering the practical resolution limit for EUV lithography [1]. This is no exaggeration, as stochastic effects have been observed for 24 nm half-pitch several years ago [2,3]. This then leads to the question of whether … Read More

Stochastic Pupil Fill in EUV Lithography

Pupil fill tradeoff again

EUV lithography continues to be plagued by its stochastic nature.

This stochastic nature is most clearly portrayed by the random fluctuation of the absorbed photon number at a given location. For example, consider an absorbed dose of 10 mJ/cm2 amounts to 6.8 photons of energy 92 eV absorbed in a square … Read More

ASML surprise not a surprise (to us)- Bifurcation- Stocks reset- China headfake

- Investors finally realize the upcycle isn’t as strong as stocks indicated

- Industry Bifurcation between AI & rest of industry continues

- China spending risk/overhang finally kicks in

- AI is super strong, majority of chips remain weak- Invest accordingly

ASML simply states chip industry reality that investors have

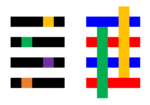

… Read MoreApplication-Specific Lithography: Patterning 5nm 5.5-Track Metal by DUV

At IEDM 2019, TSMC revealed two versions of 5nm standard cell layouts: a 5.5-track DUV-patterned version and a 6-track EUV-patterned version [1]. Although the metal pitches were not explicitly stated, later analyses of a 5nm product, namely, Apple’s A15 Bionic chip, revealed a cell height of 210 nm [2]. For the 6-track … Read More

Why NA is Not Relevant to Resolution in EUV Lithography

The latest significant development in EUV lithography technology is the arrival of High-NA systems. Theoretically, by increasing the numerical aperture, or NA, from 0.33 to 0.55, the absolute minimum half-pitch is reduced by 40%, from 10 nm to 6 nm. However, for EUV systems, we need to recognize that the EUV light (consisting … Read More

Intel High NA Adoption

On Friday April 12th Intel held a press briefing on their adoption of High NA EUV with Intel fellow and director of lithography Mark Phillips.

In 1976 Intel built Fab 4 in Oregon, the first Intel fab outside of California. With the introduction of 300mm Oregon became the only development site for Intel with large manufacturing, development,… Read More

Huawei’s and SMIC’s Requirement for 5nm Production: Improving Multipatterning Productivity

There has been much interest in Huawei’s and SMIC’s plans for 5nm production in the near future. Since there is no use of EUV in China, immersion DUV lithography (with a 76 nm pitch resolution) is expected to be used along with pitch quartering to achieve pitches in the 20-30 nm range expected for the 5nm and 3nm nodes [1].… Read More

ASML- Soft revenues & Orders – But…China 49% – Memory Improving

ASML- better EPS but weaker revenues- 2024 recovery on track

China jumps 10% to 49%- Memory looking better @59% of orders

Order lumpiness increases with ASP- EUV will be up-DUV down

“Passing Bottom” of what has been a long down cycle

Weak revenues & orders but OK EPS

Reported revenue was Euro5.3B and EPS of Euro3.11… Read More

TSMC and Synopsys Bring Breakthrough NVIDIA Computational Lithography Platform to Production

NVIDIA cuLitho Accelerates Semiconductor Manufacturing’s Most Compute-Intensive Workload by 40-60x, Opens Industry to New Generative AI Algorithms.

An incredible example of semiconductor industry partnerships was revealed during the Synopsys User Group (SNUG) last month. It started with a press release but there is much… Read More

TSMC Process Simplification for Advanced Nodes