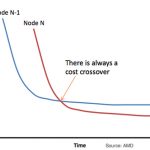

This has been a heated topic since Intel announced that it would open its manufacturing facilities to the fabless ecosystem more than a year ago. I for one think it is a colossal mistake and I’m not surprised that many others share this view. IDM’s offering of excess manufacturing capacity to semiconductor design companies started the fabless revolution so this is Deja vu all over again. Those same IDMs are now fabless, fab lite, or out of business. Right?

Intel’s first foundry customers made complete sense. Achronix and Tabula are emerging FPGA companies meaning Intel can closely control the flow of process information. Achronix was an equity investment using the ASIC model where Intel does all of the heavy lifting so the process recipe never leaves the building. Ditto for Netronome. Altera however is more the traditional foundry model and this is where Intel crossed the insanity line, absolutely.

In order for Altera to compete with the likes of Xilinx they will need full access to Intel’s process technology and the ability to co-develop a process tuned for FPGAs. Altera and TSMC did this for many years up until Xilinx joined TSMC at the 28nm node. As a result, there is going to be a big shake-up in the FPGA market share numbers at 28nm. Historically Altera and Xilinx have been close but my guess is at 28nm Xilinx will run away with 70% market share which is exactly why Altera moved to Intel (they really had no choice).

From what I am told, the first versions of the Intel 14nm design rule manual delivered to Altera were redacted like something from the FBI. That has changed over time and the fact of the matter is that Intel’s process recipes are now available in the mainstream fabless semiconductor ecosystem which might as well be public domain. There are no secrets in Silicon Valley, especially now with semiconductor social media websites like SemiWiki.com, believe it.

For example: I know what the yield problem really was at Intel 14nm. It was not double patterning as many had guessed and technically it was a defect density problem as Intel had suggested but there was much more to it than that. Simply stated, it was increased CMP slurry at wafer’s edge causing excessive curvature which significantly limited yield.

Okay, back to the foundry question. Intel will not make money from Altera for many years to come and will be lucky to break even considering what a demanding customer Altera is. Same goes for Tabula and Achronix so this whole “filling the fabs” thing is a crock. Intel is just biding time until they can land a big SoC foundry fish which I don’t see happening. I work with SoC companies and they are not going to Intel, believe it.

Qualcomm Chairman Dr. Paul Jacobs said as much at a recent analyst conference:

Qualcomm Inc. (QCOM) BMO Technology, Media & Entertainment Conference December 11, 2013

The transcript is a good read if you are into the SoC business but here is the Intel as a foundry parts:

The other part of the question was about Intel what do we see about Intel as a potential source for foundry and I mean we’re certainly open to it, it’s — there they have expressed interest in going that way obviously TSMC and the other fabless guys have a different model right now for how they build their fabs they’re very flexible. They can run multiple different products through them simultaneously and it’s all software controlled where the cartridge of wafer go and Intel is famous we have been known for having a copy exact model, so they need very large volumes of a particular chip to run through that.

But I mean people change and so forth, so I mean it’s certainly interesting I mean I am glad to hear that their interested in going that way and we’ll see how that plays out. But right now I mean the fundamental of that in the foundry is that typically these leading edge chips go into a set of iconic phones an iconic phone is like a — it’s almost like a movie launch. Things happen in the first small period of time, so you have to ramp incredibly fast, build a lot of capacity on the frontend which means that after that those first wave has passed through that now there is a lot of foundry capacity leftover.

And the fabless model have to be there in order for other people to absorb that coming later, the later waves to absorb that. So I think the fabless model is very well suited to the mobile space and to these kind of leading edge designs and so I think it’s sort of necessary as a way of participating in the market.

Spin it any way you want but based on my experience with QCOM and the other top fabless companies there is no way they will be able to work within the rigid process requirements and the strict business demands of Intel. The foundry business just does’nt work that way. Unless of course they are desperate like Altera.

My advice: If Intel wants to fill their fabs, instead of giving $1B of chips away for free (Baytrail) and whoring out their excess capacity, Intel should acquire fabless companies that are in emerging markets to better diversify and do what Intel does best, make chips!

The Intel foundry guys sat at the table next to me at the GSA Awards last week which recognized the leading fabless companies around the world. Hopefully they made a shopping list of companies to acquire that can fill their fabs and return Intel to financial growth on par with the rest of the semiconductor industry (30% versus Intel’s 0%).