When it comes to wearable technology and the rapidly emerging world of IoT, sensors and MEMS are on the frontlines. They collect and transfer raw data such as pressure, temperature and motion and process it with algorithms critical to making sure the right information gets to humans and/or machines so the right reaction is enabled.… Read More

Tag: coventor

How Microtechnology Will Change Just About Everything

When I hear the term micro-technology my first thought is of accelerometers and gyroscopes. However as I’ll explain shortly, micro technology is being applied to a lot more than smartphones and quadcopters. The fruits of development in this area will affect industry, medical, energy, transportation and many other sectors. … Read More

PDK Generation Needs Paradigm Shift

For any semiconductor technology node to be adopted in actual semiconductor designs, the very first step is to have a Process Design Kit (PDK) developed for that particular technology node and qualified through several design tools used in the design flow. The development of PDK has not been easy; it’s a tedious, time consuming,… Read More

Coventor, Lego and IoT in Denmark

Coventor were in Copenhagen Denmark a few weeks ago at the Smart Systems Integration Conference to talk about MEMS and IoT entitled (take a deep breath) Towards a Lego Block Principle for Heterogonous Systems Design Including MEMS and Electronics—Choose and Put Together Fit. Since this seems to have become IoT week for me, without… Read More

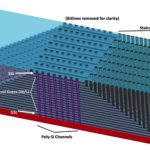

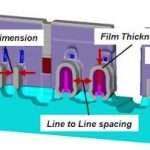

Vertical NAND Flash

You may know that up until now NAND flash has been a planar technology. But just as with SoC processes where we have had to go vertical to FinFETs, NAND flash has reached the limitations of scaling in the 20nm nodes and is also going vertical. It is not just a lithography issue but there are also reliability and voltage scaling issues.… Read More

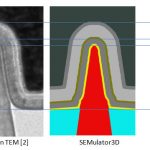

Mapping Focus and Dose onto BEOL Fabrication Effects

With today’s ArF based lithography using 193nm wavelength light, we are hard up against the limitations imposed by the Raleigh equation. Numerous clever things have been devised to maximize yield and reduce feature size. These include 2 beam lithography, multiple patterning, immersion litho processes to improve NA, thinner… Read More

IoT Sensor Node Designs Call for Highly Integrated Flows

Applications for IoT sensors are becoming more sophisticated, especially for industrial usage. Building optimal sensors for different applications requires multi-domain design, optimization and verification flows. The sensor devices are usually MEMS, and as such have electrical properties that need to be tailored to … Read More

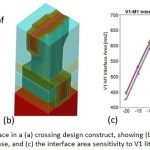

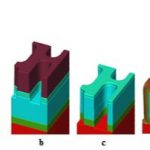

Chips Are Going 3D, DRC Needs to Go 3D Too

The last paradigm shift in DRC was around 0.35um when designs got too large to handle as flat data, and hierarchical approaches were required. Back then the design rules themselves were not that complex, the explosion of data volume came from the complexity of the design itself. But each process node added more design rules intricacies… Read More

Coventor Panel at IEDM Digs into Variation Issues

Recently I attended a panel discussion on variability in semiconductor fabrication hosted by Coventor in conjunction with the IEEE IEDM conference in San Francisco. The IEEE bills the conference as “the world’s pre-eminent forum for reporting technological breakthroughs in the areas of semiconductor and electronic device… Read More

Variation: How Can We Survive?

At IEDM last week Coventor hosted a panel session as they do each year. The theme this year was surviving variation. The panel was hosted by someone whose name is familiar round here, Dan Nenni. The panel that Coventor had put together had people from all sorts of different slots in the design/supply chain for semiconductor. Unfortunately… Read More