As industries become more reliant on advanced technologies, the importance of ensuring the reliability and longevity of critical systems grows. Failures in components, whether in autonomous vehicles, high performance computing (HPC), healthcare devices, or industrial automation, can have far-reaching consequences. Predicting and preventing failures is essential, and technologies like Digital Twins and Silicon Lifecycle Management (SLM) are key to achieving this. These tools provide the ability to monitor, analyze, and predict failures, thereby improving the dependability, and performance of systems.

“The reliability, availability, and serviceability (RAS) of complex systems such as data center infrastructure has never been more complex or critical,” said Jyotika Athavale, director of Engineering Architecture at Synopsys. “By integrating silicon health with digital twin simulations, we unlock powerful new capabilities for predictive modeling. This enables technology leaders to optimize system design and performance in new, impactful ways.”

Athavale addressed this topic during a talk she delivered at the Supercomputing Conference 2024 recently. She leads quality, reliability and safety research, pathfinding, standards and architectures for SLM solutions across RAS sensitive application domains.

Why Digital Twins Are Good for Prognostics

A Digital Twin is a virtual replica of a physical asset, created by combining real-time sensor data with simulation models. Digital twins enable continuous monitoring of system health and provide valuable insights for prognostics, which is the process of predicting future failures. By simulating different scenarios, digital twins can predict Remaining Useful Life (RUL), helping operators plan maintenance or replacements before a failure occurs. RUL refers to the time a device or component is expected to function within its specifications before failure. This proactive approach reduces downtime and optimizes system resources.

Types of Failures in Modern Systems

Failures in modern systems are categorized into permanent, transient and intermittent faults. Permanent faults, such as Time-Dependent Dielectric Breakdown (TDDB), Negative Bias Temperature Instability (NBTI), and Hot Carrier Injection (HCI), occur over time and lead to errors resulting in failure. In contrast, transient faults are temporary disruptions caused by external factors like radiation, which do not result in lasting damage.

In sub-20nm process technologies, degrading defects continue to evolve into the useful life phase of the bathtub curve, leading to issues like Silent Data Corruption (SDC), which can go unnoticed until critical failure occurs.

Why Failures Are Increasing

Despite technological advancements, failures are rising due to several factors. As devices shrink in size and increase in complexity, they become more vulnerable to failure. Smaller transistors, particularly below 20nm, are more susceptible to intrinsic wearout. Moreover, the demand for higher performance leads to greater stress on semiconductors. With interconnected systems in critical applications, even a single failure can have serious consequences, making predictive maintenance even more essential.

“To keep pace with these challenges, it’s essential to shift from reactive to predictive maintenance strategies,” said Athavale. “By integrating real-time monitoring and predictive insights at the silicon level, we can better manage the complexities of modern systems, helping avoid potential failures and make maintenance more manageable..”

How to Monitor Silicon Health

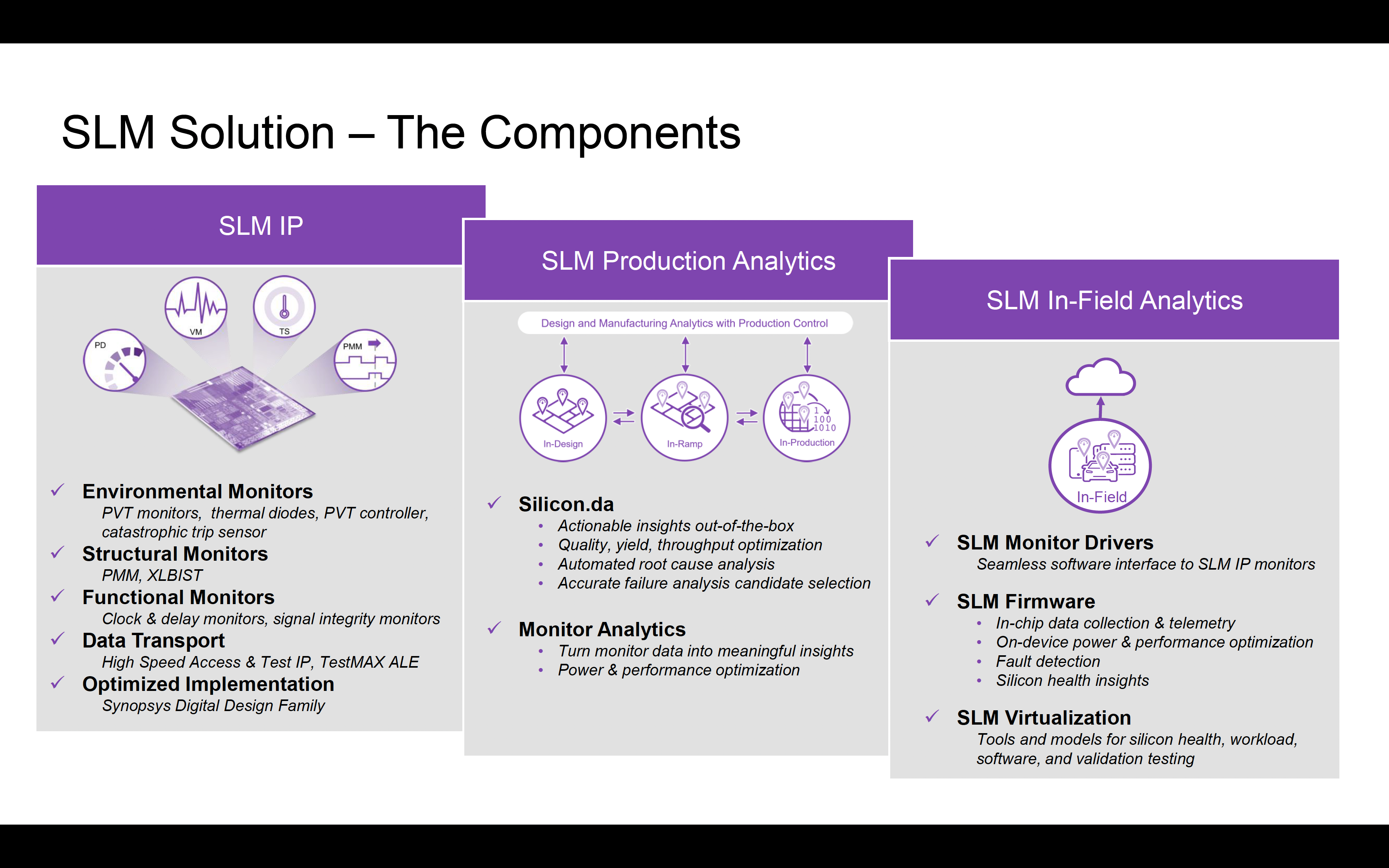

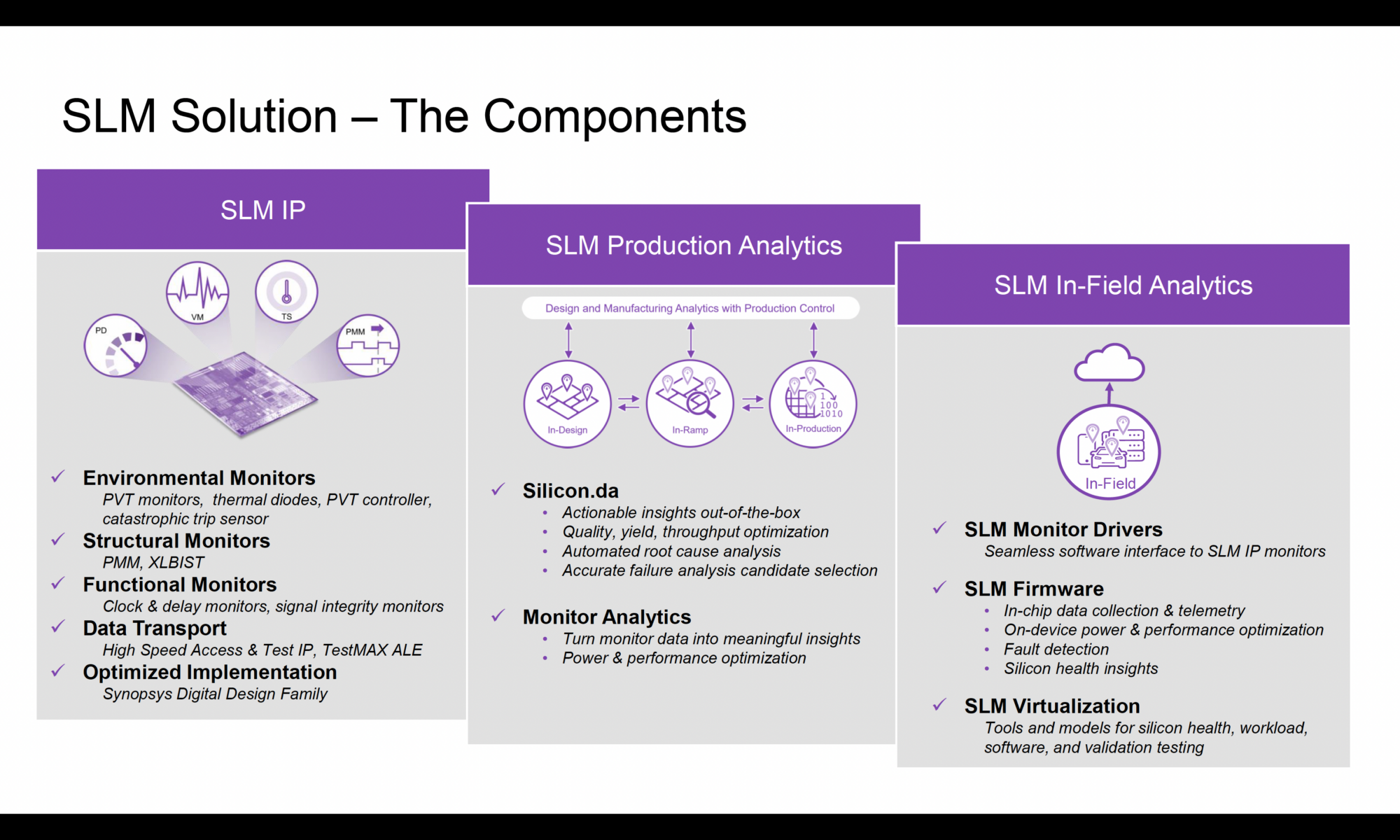

Monitoring the health of semiconductor devices is crucial for identifying early signs of degradation. With embedded monitors integrated during the design phase, data on key performance metrics—such as voltage, temperature, and timing—can be continuously collected and analyzed. Silicon Lifecycle Management (SLM) systems include PVT monitors to track process, voltage, and temperature variations, path margin monitors to ensure signal paths remain within safe operating margins, and clock delay monitors to detect timing deviations. SLM also includes in-field analytics, which enables real-time monitoring and proactive decision-making throughout the device lifecycle.

Analyzing and Predicting Failures

Once the data is collected, it is analyzed to detect potential failures. Prognostic systems use advanced algorithms to analyze degradation patterns, such as those caused by TDDB, NBTI, and HCI, to predict when a component might fail. Predicting RUL is vital for managing system reliability, as early identification of failure allows for corrective actions like maintenance or replacement before the failure occurs.

RUL Prediction Using Synopsys SLM Data Solution

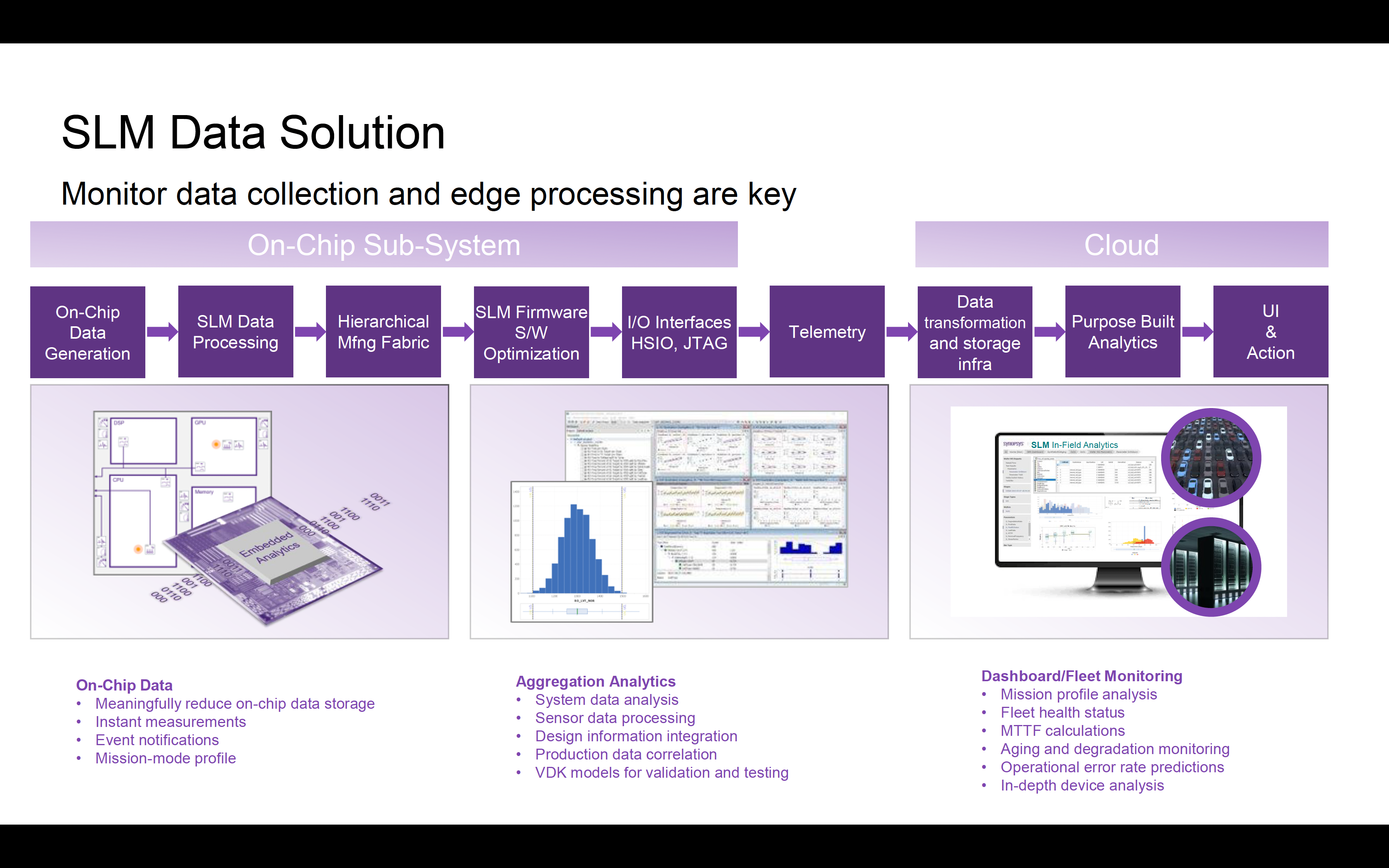

Synopsys’ SLM solution enables accurate RUL predictions through advanced monitoring and analytics, ensuring predictive maintenance and enhanced device reliability.

Key components of the Synopsys SLM solution include SLM PVT Monitors, which track process, voltage, and temperature variations to assess wear; SLM Path Margin Monitors, which detect timing degradation in critical paths; SLM Clock Delay Monitors, which identify clock-related performance anomalies; and SLM In-Field Analytics, which analyzes real-time data to predict failure trends.

The benefits of RUL prediction with Synopsys SLM include predictive maintenance, optimized reliability vs. performance, lifecycle and end-of-life planning, outlier detection, and catastrophic failure prevention. Corrective actions based on RUL analysis can include early decisions on recalls, implementing lifetime-extending mitigation strategies, and transitioning devices to a safe state to prevent further damage. Synopsys SLM provides actionable insights to minimize downtime, extend device lifespan, and ensure reliable performance throughout the lifecycle of semiconductor devices.

Summary

The combination of digital twins and Silicon Lifecycle Management (SLM) provides a powerful approach to managing the health and reliability of semiconductor devices. By enabling continuous monitoring, accurate failure prediction, and timely corrective actions, these technologies offer organizations tools to improve dependability, optimize performance, and reduce downtime. As electronic systems grow more complex and mission-critical, digital twins and SLM are becoming essential for predictive maintenance, ensuring long-term system reliability, and preventing costly failures.

Also Read:

A Master Class with Ansys and Synopsys, The Latest Advances in Multi-Die Design

The Immensity of Software Development and the Challenges of Debugging Series (Part 4 of 4)

Synopsys-Ansys 2.5D/3D Multi-Die Design Update: Learning from the Early Adopters

Share this post via:

Comments

There are no comments yet.

You must register or log in to view/post comments.