Mentor Graphics made a big announcement regarding SOC extraction at their User2User conference in San Jose during April. Before I get to the meat of the announcement, I’d like to reflect back on the early days of Calibre-DRC at Mentor. I was in Sales at Mentor around 1999, and Calibre-DRC was the new kid on the block. We had to go convince Dracula (yes, remember?) users that they could get the same accuracy with no rule deck rewrite in a fraction of the time. Well seeing was believing: usually once someone to tried Calibre-DRC, they went with it.

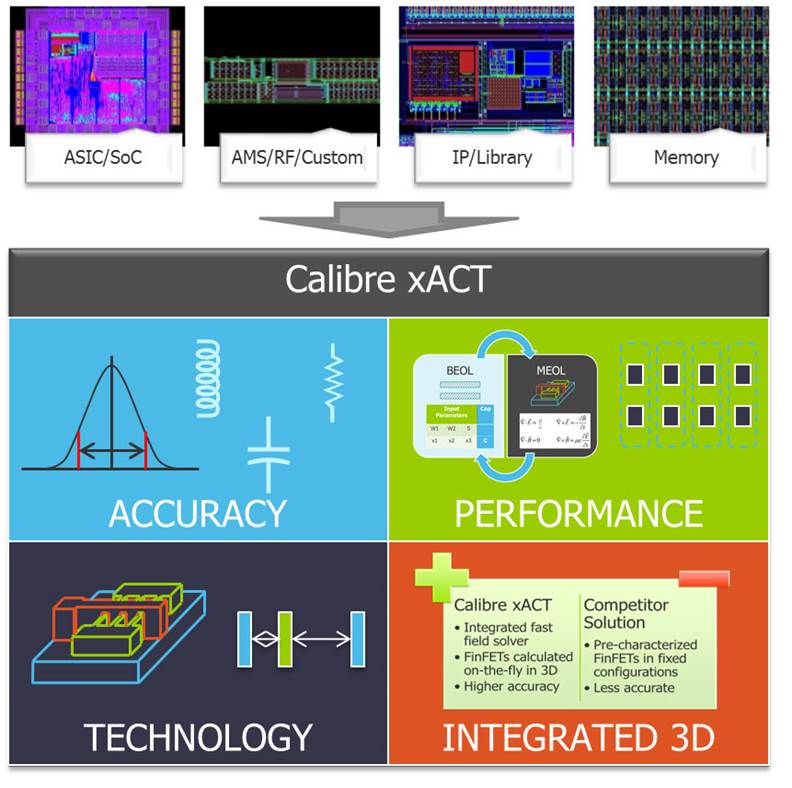

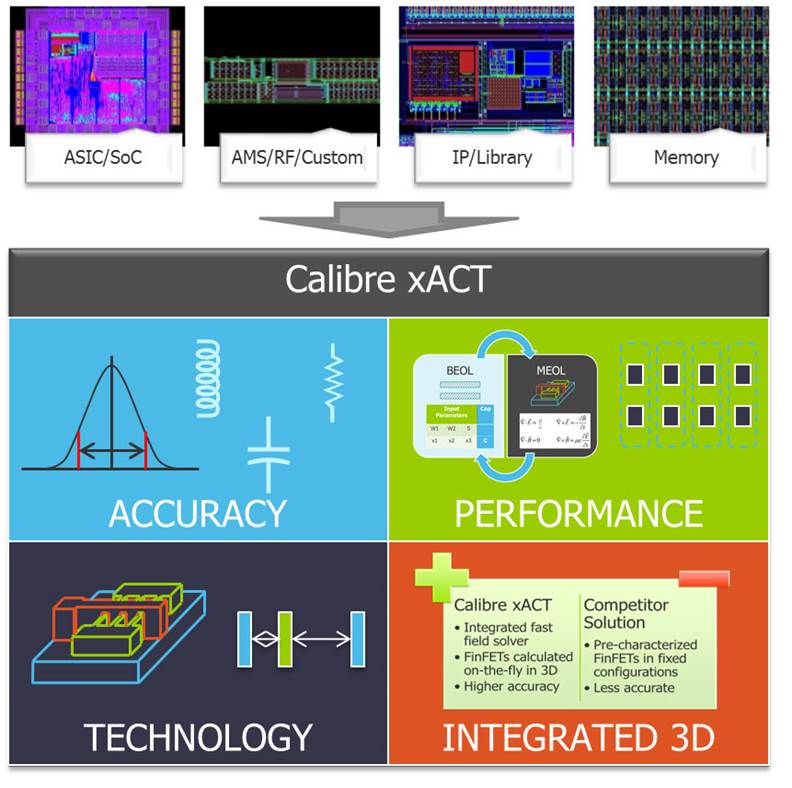

As we all know, today Calibre-DRC is the “go to” tool for DRC, and Calibre xACT is sort of the new kid on the block. In the same spirit as Calibre-DRC in those days, xACT is now making use of sophisticated optimizations to provide breathtaking gains in performance. This is, after all, how Calibre-DRC made its name – by embracing a new paradigm. There are a couple of exciting new ideas being deployed in xACT.

Previously, existing extraction too used tiles to achieve parallelism. The number of tiles determined the degree of parallelism that could be utilized. But, analysis at the edges of the tiles always caused accuracy issues. xACT uses net based parallelism; so the analysis problem can be spread over a large number of processors/CPU’s with no artifacts from tile boundaries degrading the results. But a much bigger win comes from running multiple corners in a single run. Yes, you read that correctly. Mentor R&D figured out how to run additional corners with only a ~15% increase in run time and memory. This harkens back to the seemingly unbelievable performance results that hierarchical DRC in Calibre promised. Designers will now be able to easily add the new double patterning variation corners to the already numerous process corners that they would like to run.

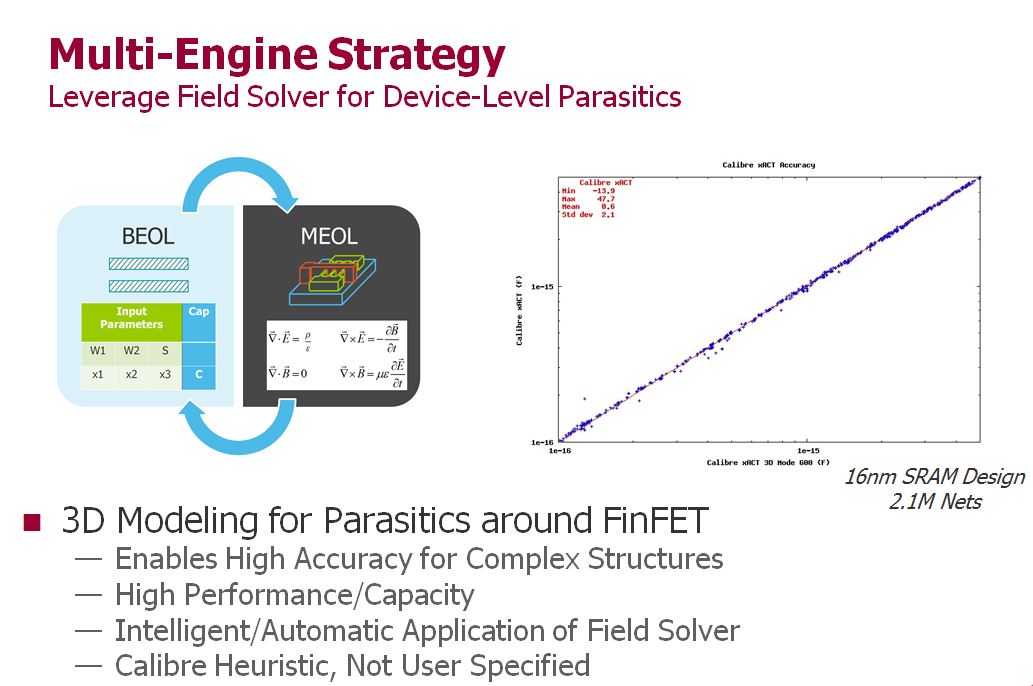

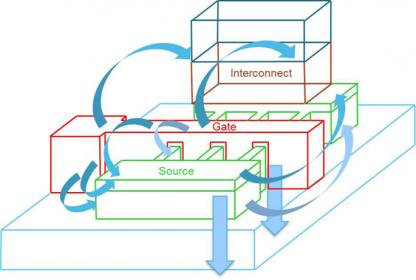

xACT is also addressing proximity effects by seamlessly incorporating a 3D field solver for parasitic extraction around devices, such as FinFET’s. What’s really nice is that there is no need to switch rule decks or run devices in situ in a separate tool. xACT automatically uses the solver when it needs to, and avoids double counting in the process.

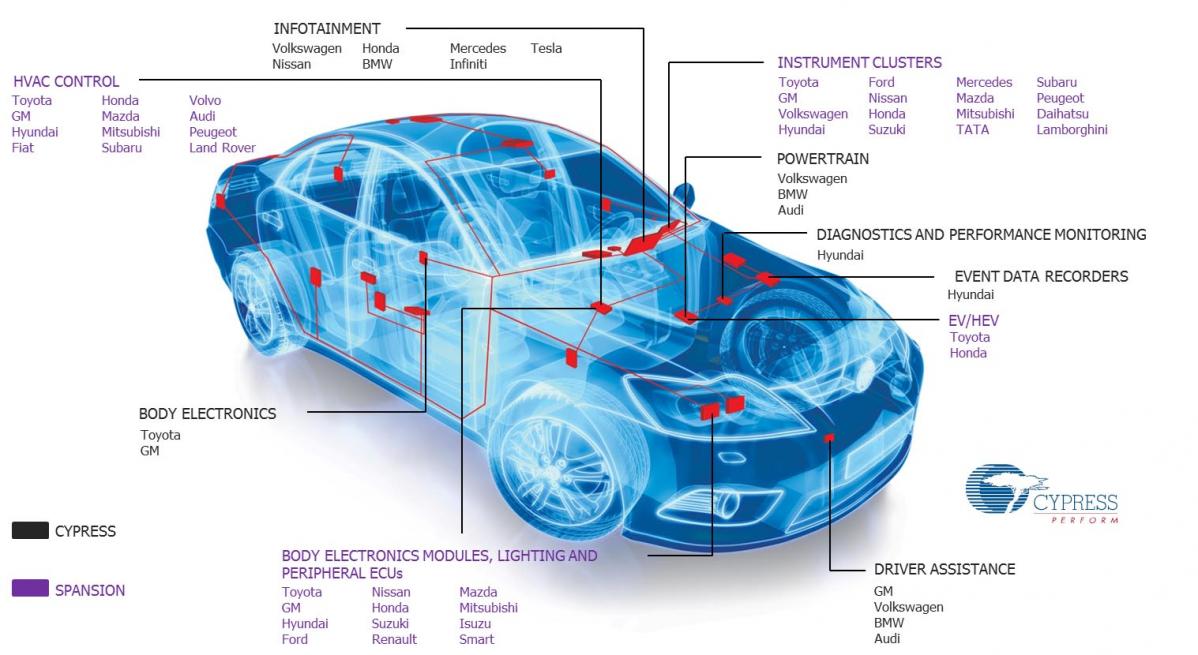

There is a lot more to the details of what is offered in xACT, but just like before seeing is believing. It turns out that my friend Bo Gao, who is a Director of Engineering at Cypress, was giving a talk on his experience with Calibre-xACT at the U2U meeting. Their design profile leans toward older nodes, their challenges with difficult end-product environments means they need to thoroughly run many corners to ensure reliability. As a result of their merger with Spansion, they have a large market share in the automotive space, where reliability is extremely important. Cypress is also a leader in SRAM and NOR Flash.

Cypress TrueTouch and CapSense controllers demand attofarad sensitivity. They also focus on ultra low power products for mobile designs. Lastly, noise management is big issue for them. The flow they use requires parasitic output that is used in a variety of tools, some of which need different formats. Fortunately xACT is very flexible when it comes to regenerating different output file formats from its persistent parasitics database.

So what did Bo observe when using xACT during his beta test experience? He ran several test cases: one at 130nm, another at 65nm and one at 28nm. Design speeds ranges up to about 1.5GHz. Bo reported excellent correlation with their golden field solver. When he ran xACt against the “other’ tool, the correlation charts for R and C had a slope of one and were tightly clustered. In his LEF/DEF flow he saw memory size go from 735B to 72MB, and run tine to from 2:20 to 0:30. In his GDS flow he saw memory go from 25.7GB to 4.5GB and runtime go from 14:45 to 3:05. So it would seem based on this that xACT lives up to Mentor’s claims. Cypress was able to integrate xACT into their flow and was happy enough about the tool to be willing to talk about their experience.

As I previously mentioned, Mentor also is announcing capacity improvements and other significant features. If you want to get the full picture I suggest downloading and reading their complete white paper on Calibre xACt for nm design through 16nm and beyond.

Mentor has been developing and assembling through acquisition strong technology over the last few years and is differentiating itself from its competitors. I look forward to what is coming next from them.

Share this post via:

Comments

There are no comments yet.

You must register or log in to view/post comments.