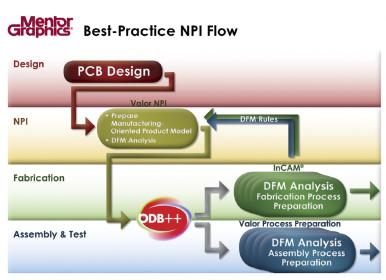

Getting a printed circuit board from design and into production presents one of the biggest challenges in successfully launching a product. The designer’s job is to anticipate issues that can adversely affect PCB fabrication and assembly. Design rules and component libraries go part of the way, but there is a thicket of things that determine how many iterations will be needed with the manufacturers and how quickly volume production can start at high yield.

I attended a presentation recently that was given by Julian Coates from Mentor’s Valor Division on their NPI (New Product Introduction) offering. Valor products are well known and widely used by PCB fab and assembly houses. But very often designers rely on their vendors to run it to provide feedback. This was confirmed by a friend of mine whose company does contract board design, “I just let them run it and tell me if there are any issues.” But he conceded that Valor provided much needed information to ensure manufacturability. An example of one such issue is where a net touches itself and creates clearance issues for reflow soldering. It’s not a short, but can cause bad solder connections. Valor can spot these kinds of issues easily.

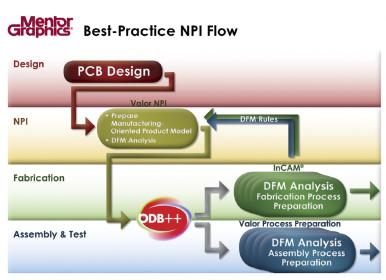

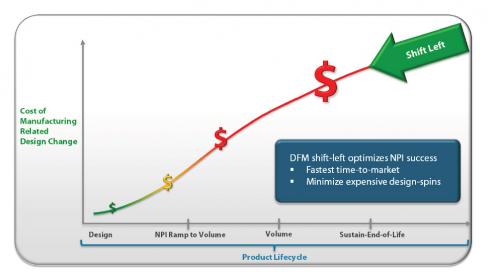

Valor NPI is intended for designers and NPI engineers to run during the design phase. By pulling necessary changes forward in the design process, it reduces costs. Mentor’s Julian Coates cites a study that shows the use of Valor NPI can reduce the average number of design to fab house iterations from 2.8 to 1.5. Given that each turn will have associated costs, this represents a big savings in money and time.

Mentor’s challenge is to get designers and NPI engineers to run the tool themselves. This means leaving Allegro, for instance, and getting into Valor. Mentor explained that they have interactive integration to make this convenient.

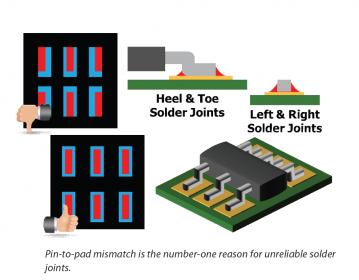

Often there are multiple sources for parts and multiple fab and assembly providers. Valor NPI can help with each of these. The PCB editor parts library is actually just shapes for the copper and board, not actual part geometry. If you dig into the inventory parts that might be used for a given SMT device, you will see subtle variations of the terminal geometry. Not all 0402 10K resistors are exactly the same. Locking in to just one supplier could affect the supply chain. Valor NPI addresses this by complimenting the PCB editor library with their physical parts library with thousands of actual device dimensions. This means that for all alternative devices, it is possible to see exactly how the pins will contact the PCB, showing if the pad geometry will work well for all possible inventory parts. The same goes for pad position as well as size. Badly positioned pins on pads will cause bad solder joints and is a leading cause of PCB failure.

Lastly one of the examples I appreciated the most was the case where the solder stencil opening for a pin touched a nearby net. Valor flags this kind of issue, avoiding solder bridges leading to design failure.

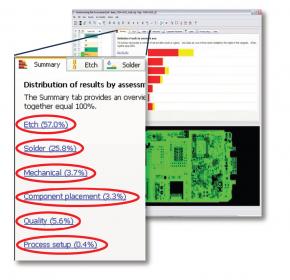

DFM rules vary between fab and assembly suppliers. Valor NPI can maintain different DFM rules for each vendor. One of the attendees at the event mentioned that they always use multiple vendors for manufacturing. Being able to run all the vendors’ DFM rules seems like a good capability to ensure manufacturability during design. Valor NPI also adds a qualitative aspect to DFM. It does not just provide pass/fail for DFM checks. It encourages practices to boost yield by advising when certain dimensions are reaching critical values. You might have a reason for 6 mil spacing in specific locations, but you probably want to avoid it where you can even if it is OK within the design rules. Valor NPI will give you a histogram showing red and yellow rule warnings, as well as black hard violations.

Valor NPI also lets designers do their own panelization. It handles all the tricky issues with outline milling with mouse bites, and v-grooves. In addition to fiducals, if rails are deemed necessary they can be added. The Valor parts library is helpful here because it has the physical dimensions for connectors and potentially overhanging components that would cause issues during assembly.

PCB manufacturability is a huge issue. Mentor has impressive expertise in PCB supply chain tools. Valor NPI applies this expertise to provide a compelling solution for the design side of the business. The only question is if they can convince designers and NPI engineers to adopt their proposed process. It seems that the business case for doing so is strong.

They will let you try it free for 5 days. More information about Mentor’s Valor NPI can be found here.

Share this post via:

Comments

There are no comments yet.

You must register or log in to view/post comments.