From Zion Research I learned that the flexible electronics market was about $13.2B in 2021 and growing at a CAGR of 21%, so that was impressive. There are several factors that make rigid-flex circuit so attractive, like: space efficiency, reduced weight, enhanced reliability, improved signal integrity, streamlined assembly,… Read More

Tag: dfm

ECO Demo Update from Easy-Logic

I first met Jimmy Chen from Easy-Logic at #60DAC and wrote about their Engineering Change Order (ECO) tool in August 2023. Recently we had a Zoom call so that I could see a live demo of their EDA tool in action. Allen Guo, the AE Manager for Easy-Logic gave me an overview presentation of the company and some history to provide a bit of context.… Read More

Empyrean Technology‘s Complete Design Solution for PMIC

Power management integrated circuits (PMICs) are integrated circuits for power management. Driven by the strong demand in consumer electronics, IoT, and the automobile industry, the design for PMIC is getting more challenging in terms of integration, reliability and efficiency. The design methodology needs to be updated… Read More

Symmetry Requirements Becoming More Important and Challenging

Humans certainly have always had an aesthetic preference for symmetry. We also see symmetry showing up frequently in nature. The importance of symmetry in electronic designs has been apparent for decades. There are a host of analog structures that require balanced layout. For instance, these include differential pairs and … Read More

EDA in the Cloud – Now More Than Ever

A decade ago, many of us heard commentaries on how entrepreneurs were turned down by venture capitalists for not including a cloud strategy in their business plan, no matter what the core business was. Humorous punchlines such as, “It’s cloudy without any clouds” and “Add some cloud to your strategy and your future will be bright… Read More

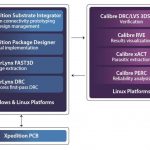

Calibre DFM Adds Bidirectional DEF Integration

GDS and LEF/DEF each came about to support data exchange in different types of design flows, custom layout and place & route respectively. GDS (or stream format) was first created in the late 1970s to support the first generation of custom IC layout tools, such as Calma’s GDSII system. Of course, the GDS format has been updated… Read More

Saving Time in Physical Verification by Reusing Metadata

Physical verification is an important and necessary step in the process to tapeout an IC design, and the foundries define sign-off qualification steps for:

- Physical validation

- Circuit validation

- Reliability verification

This sounds quite reasonable until you actually go through the steps only to discover that some of the … Read More

Tools for Advanced Packaging Design Follow Moore’s Law, Too!

There is an emerging set of advanced packaging technologies that enables unique product designs, with the capability to integrate multiple die, from potentially heterogeneous technologies. These “system-in-package” (SiP) offerings provide architects with the opportunity to optimize product performance, power, cost,… Read More

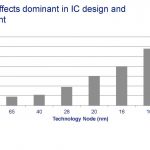

Noise, The Need for Speed, and Machine Learning

Technology trends make the concerns with electronic noise a primary constraint that impacts many mainstream products, driving the need for “Design-for-Noise” practices. That is, scaling, and the associated reduction in the device operating voltage and current, in effect magnifies the relative importance of non-scalable… Read More

SPIE 2017 ASML and Cadence EUV impact on place and route

As feature sizes have shrunk, the semiconductor industry has moved from simple, single-exposure lithography solutions to increasingly complex resolution-enhancement techniques and multi-patterning. Where the design on a mask once matched the image that would be produced on the wafer, today the mask and resulting image … Read More