You are currently viewing SemiWiki as a guest which gives you limited access to the site. To view blog comments and experience other SemiWiki features you must be a registered member. Registration is fast, simple, and absolutely free so please,

join our community today!

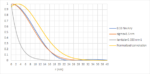

It has recently been revealed that the N5 node from TSMC has a minimum gate pitch of 51 nm [1,2] with a channel length as small as 6 nm [2]. Such a tight channel length entails tight CD control in the patterning process, well under 0.5 nm. What are the possible lithography scenarios?

Blur Limitations for EUV Exposure

A state-of-the-art

…

Read More

There is growing awareness that EUV lithography is actually an imaging technique that heavily depends on the distribution of secondary electrons in the resist layer [1-5]. The stochastic aspects should be traced not only to the discrete number of photons absorbed but also the electrons that are subsequently released. The electron… Read More

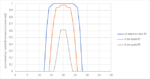

The 3nm node is projected to feature around a 22 nm metal pitch [1,2]. This poses some new challenges for the use of EUV lithography. Some challenges are different for the 0.33NA vs. 0.55NA systems.

0.33 NA

For 0.33 NA systems, 22 nm pitch can only be supported by illumination filling 4% of the pupil, well below the 20% lower limit for

…

Read More

The next generation of EUV lithography systems are based on a numerical aperture (NA) of 0.55, a 67% increase from the current value of 0.33. It targets being able to print 16 nm pitch [1]. The High-NA systems are already expected to face complications from four issues: (1) reduced depth-of-focus requires thinner resists, which… Read More

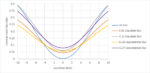

To the general public, EUV lithography’s resolution can be traced back to its short wavelengths (13.2-13.8 nm), but the true printed resolution has always been affected by the stochastic behavior of the electrons released by EUV absorption [1-5].

A 0.33 NA EUV system is expected to have a diffraction-limited point spread… Read More

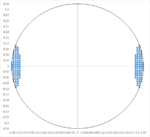

At this year’s SPIE Advanced Lithography conference, changes to EUV masks were particularly highlighted, as a better understanding of their behavior is becoming clear. It’s now confirmed that a seemingly symmetric EUV mask absorber pattern does not produce a symmetric image at the wafer, as a conventional DUV … Read More

As a consequence of having a ~13.5 nm wavelength, EUV photons transfer ~90% of their energy to ionized photoelectrons. Thus, EUV lithography is fundamentally mostly EUV photoelectron lithography. The actual resolution becomes dependent on photoelectron trajectories.

Photoelectron trajectories in EUV lithography were… Read More

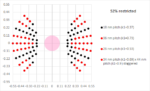

The list of possible stochastic patterning issues for EUV lithography keeps growing longer: CD variation, edge roughness, placement error, defects [1]. The origins of stochastic behavior are now well-known. For a given EUV photon flux into the resist, a limited fraction are absorbed. Since the absorption is less than 5% affected… Read More

Stochastic defects continue to draw attention in the area of EUV lithography. It is now widely recognized that stochastic issues not only come from photon shot noise due to low (absorbed) EUV photon density, but also the resist material and process factors [1-4].

It stands to reason that resist absorption of EUV light, which is … Read More

The 5nm foundry node saw the arrival of 6-track standard cells with four narrow routing tracks between wide power/ground rails (Figure 1a), with minimum pitches of around 30 nm [1]. The routing tracks require cuts [2] with widths comparable to the minimum half-pitch, to enable the via connections to the next metal layer with the… Read More

CEO Interview with Aftkhar Aslam of yieldWerx