In the past ESD sign-off has been accomplished by a combination of techniques. Often ESD experts are asked to look at a design and assess its ESD robustness based on experience gained from prior chips. Alternatively, designers are told to work with a set of rules given to them, again based on previous experience about what usually… Read More

Tag: hbm

Enabling Next Generation Silicon In Package Products

In early April, Gabriele Saucier kicked off Design & Reuse’s IPSoC Silicon Valley 2021 Conference. IPSoC conference as the name suggests is dedicated to semiconductor intellectual property (IP) and IP-based electronic systems. There were a number of excellent presentations at the conference. The presentations had been… Read More

Verification IP Coverage

I am pleased to introduce Truechip to the SemiWiki community. Truechip is a leader in the IP Verification – Design and Verification solutions market, one of the fastest growing market segments we track. Truechip has been serving customers for more than 10 years specialization in VIP integration, customization and SOC Verification.… Read More

Webinar Replay – Designing and Verifying HBM ESD Protection Networks

Every chip needs ESD protection, especially RF, analog and nm designs. Because each type of design has specific needs relating to IOs, pad rings, operating voltage, process, etc. it is important that the ESD protection network is carefully tailored to the design. Also because of interactions between the design and its ESD protection… Read More

Thermo-compression bonding for Large Stacked HBM Die

Summary

Thermo-compression bonding is used in heterogeneous 3D packaging technology – this attach method was applied to the assembly of large (12-stack and 16-stack) high bandwidth memory (HBM) die, with significant bandwidth and power improvements over traditional microbump attach.

Introduction

The rapid growth of heterogeneous… Read More

Free Webinar on Verifying On-Chip ESD Protection

Walking across a carpet can generate up to 35,000 volts of static charge, which is tens of thousands of times higher than the operating voltages of most integrated circuits. When charge build up from static electricity is exposed to the pins of an IC, the electrostatic discharge (ESD) protection network on the chip is intended to… Read More

Adding CDM Protection to a Real World LNA Test Case

In RF designs Low Noise Amplifiers (LNA) play a critical role in system operation. They simultaneously need to be extremely sensitive and noise free, yet also must be able to withstand strong signal input without distortion. LNA designers often struggle to meet device performance specifications. Their task is further complicated… Read More

Upcoming HBM and CDM ESD Verification Seminar in Taiwan

The electrostatic discharge that occurs in lightening, as seen in the picture below, can cause serious damage to the objects on the ground. Over centuries mankind has devised ways, such as lighting rods and arresters, to deflect the energy so it is dissipated harmlessly. The same drama plays out on modern semiconductors due to … Read More

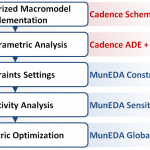

A Practical Approach to Modeling ESD Protection Devices for Circuit Simulation

Lurking inside of every Mosfet is a parasitic bipolar junction transistor (BJT). Of course, in normal circuit operation the BJT does not play a role in the device operation. Accordingly, SPICE models for Mosfets do not behave well when the BJT is triggered. However, these models work just fine for most purposes. The one important… Read More

TSMC Q3 2018 Earnings Call Discussion!

The TSMC OIP Forum was very upbeat this year and now we know why. It wasn’t long ago that some media outlets and a competitor said 7nm would not be a popular node because it is too expensive blah blah blah. People inside the fabless semiconductor ecosystem however know otherwise. As I have said before, 7nm will be another strong node … Read More