Predictions in technology adoption often hinge on a delicate balance between technical feasibility and market dynamics. While business considerations play a pivotal role, the technical category reasons for the success or failure of a prediction are more tangible and often easier to identify—if scrutinized with care. However, over-exuberance and a tendency to overlook these technical realities frequently lead to inaccurate forecasts.

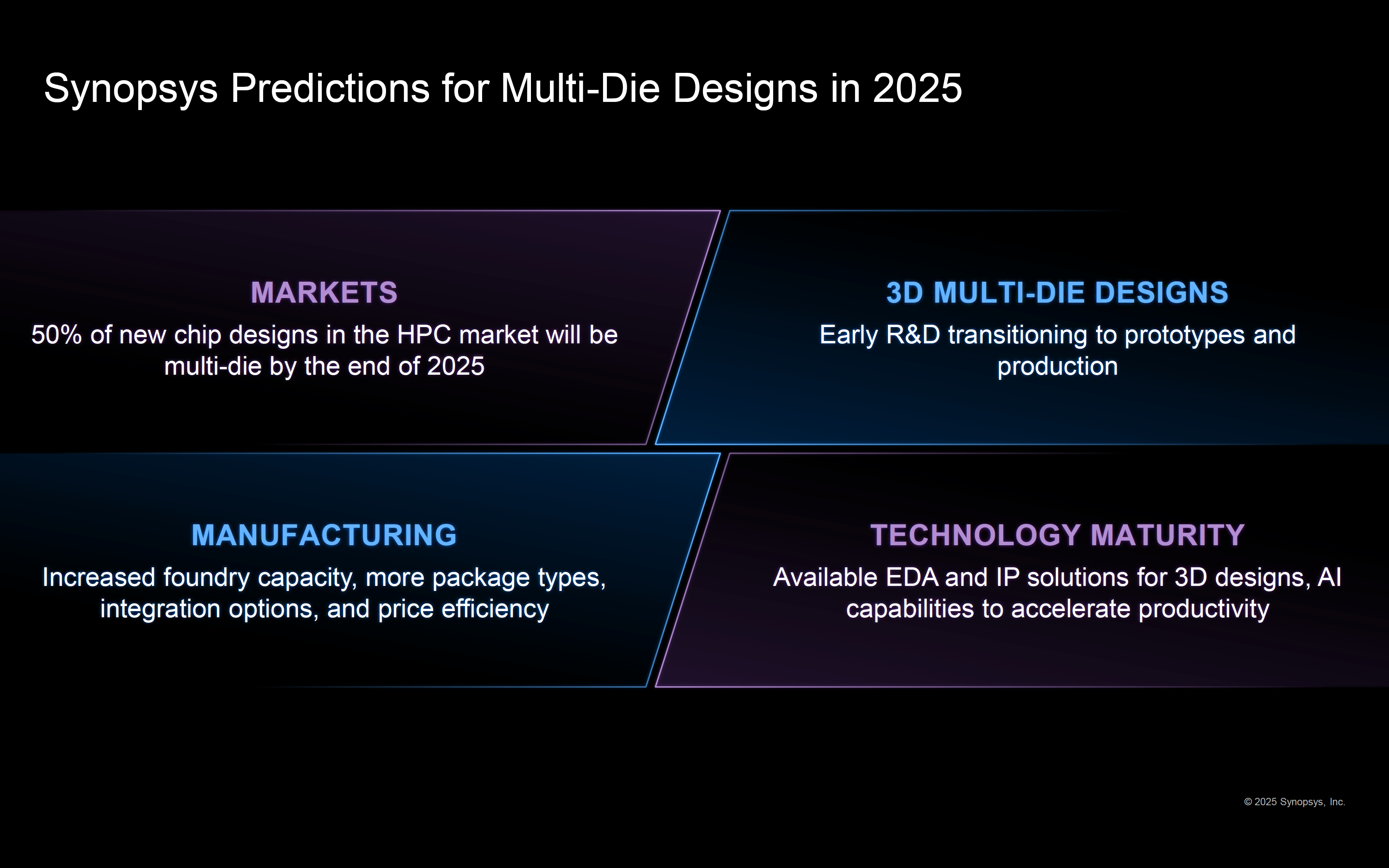

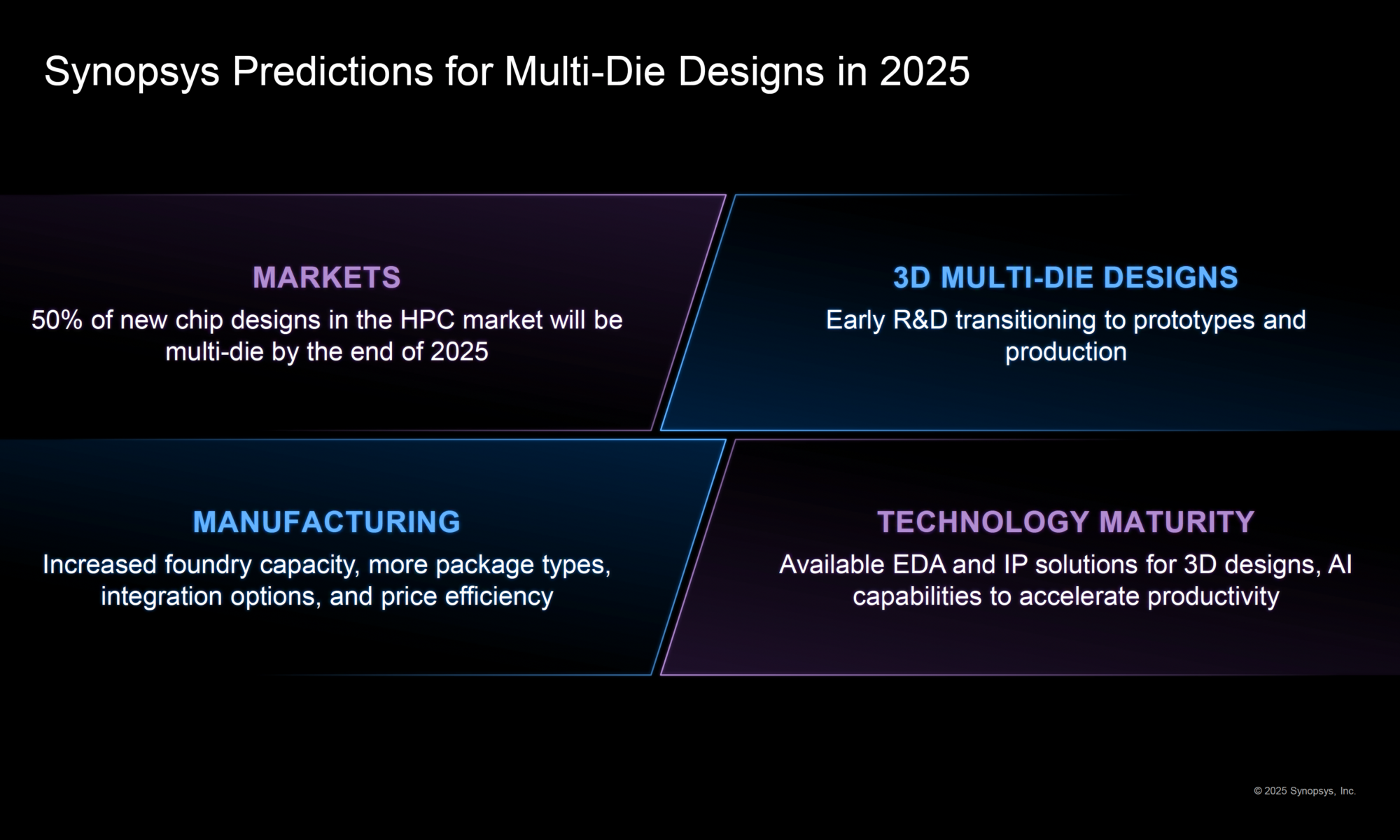

Abhijeet Chakraborty, Vice President of Engineering at Synopsys gave a keynote talk at the Chiplet Summit 2025. His presentation titled “Accelerating AI Chip Development with 3D Multi-Die Designs” closed with a Synopsys prediction of 50% of new chip designs in the HPC market being multi-die by the end of 2025.

A situational analysis may help us get comfortable with that prediction and why the present moment is uniquely suited for widespread adoption of multi-die design implementations. I chatted with Shekhar Kapoor, Executive Director, Product Management at Synopsys to gain additional insights for this purpose.

The Hurdles of Multi-Die Solutions in the Past

Multi-die solutions have long promised improved performance, efficiency, and scalability over monolithic chip designs, but their adoption was historically constrained by technical and economic challenges. Immature interconnect technologies lacked the high bandwidth and low latency needed for seamless communication, while thermal management struggled with heat dissipation from closely packed high-performance components. Power delivery was another hurdle, as stable, efficient supply systems for diverse die requirements were underdeveloped. Additionally, rising interconnect densities led to signal integrity and electromagnetic interference (EMI) issues.

Standardized chiplet interfaces were absent, limiting design flexibility and cross-vendor compatibility. Economically, advanced packaging methods like interposers and 3D stacking were costly and lacked scalable supply chains. Moreover, testing and validation complexities added to development costs and time-to-market delays.

How the Hurdles Have Evolved

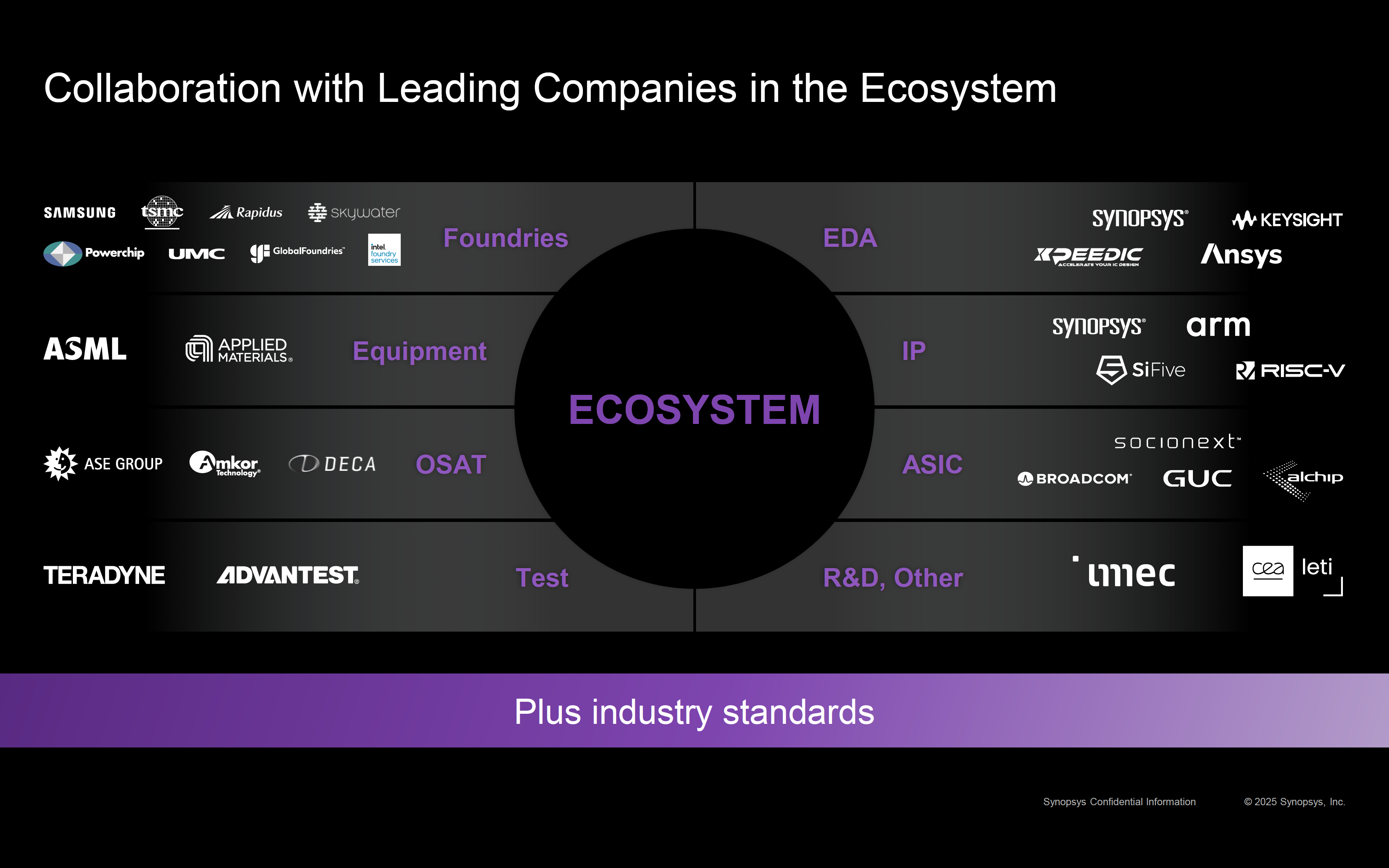

Advancements in technology and industry collaboration have resolved many barriers to multi-die solutions. High-speed interconnects like through-silicon vias (TSVs) and silicon interposers now enable efficient, low-latency communication, while open standards like UCIe enhance interoperability across vendors.

Thermal management has improved with advanced cooling techniques and optimized packaging designs, ensuring reliable operation even in 3D-stacked configurations. Power delivery challenges have been addressed with sophisticated management systems, enabling stable and efficient power for diverse dies.

The Benefits of Multi-Die Solutions

The benefits of multi-die solutions are transformative, addressing many of the limitations of traditional monolithic designs. By integrating multiple dies within a single package, these architectures achieve higher performance through improved interconnectivity and reduced latency. Design flexibility is another key advantage, allowing heterogeneous components such as processors, accelerators, and memory to be combined and optimized for specific workloads.

From an economic perspective, multi-die architectures provide a cost-effective path forward as semiconductor nodes approach their physical and economic limits. Smaller dies manufactured on mature nodes can be combined using advanced packaging, reducing costs while maintaining high performance. This modular approach also improves yield and scalability, facilitating faster development cycles and enabling the rapid adoption of emerging technologies.

Why the Timing Is Right for Multi-Die Solutions

The adoption of multi-die solutions is primed for takeoff, driven by technological advancements, market demand, and economic pressures. Applications like AI, high-performance computing, and data analytics require scalable, energy-efficient architectures, which multi-die designs provide. Mature interconnect, thermal management, and power delivery technologies now enable high-volume production, while standardized interfaces like UCIe foster collaboration and reduce costs.

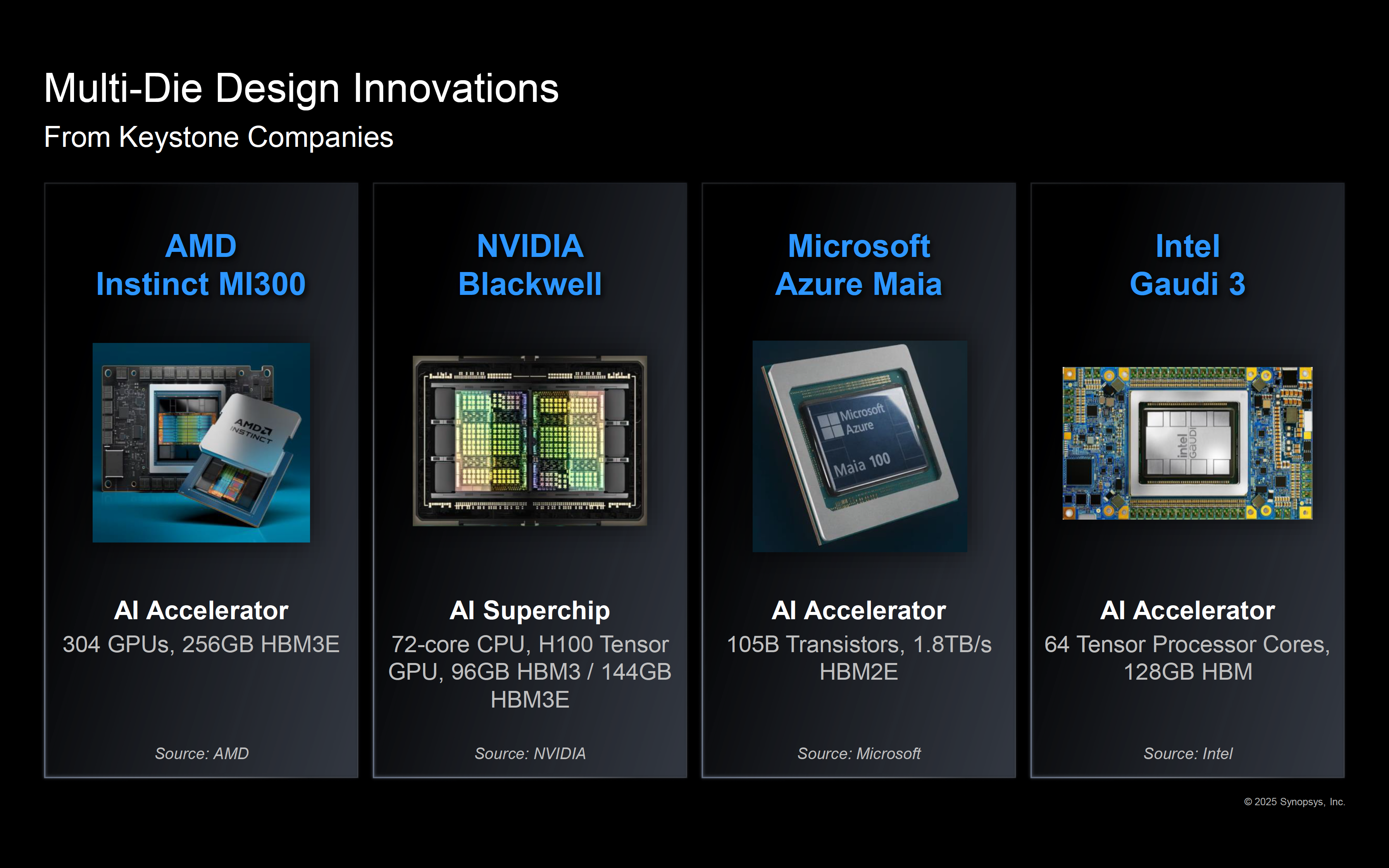

Rising process node costs further underscore the economic value of multi-die solutions, as demonstrated by industry leaders AMD, Intel, Microsoft and NVIDIA in their flagship products. These architectures align with market demands and sustainability goals, offering a cost-effective path to high performance.

Additionally, ecosystem growth fueled by robust supply chains, tools and IP has simplified design and integration, enabled reduced costs and accelerated time-to-market for multi-die systems. Synopsys’ 3DIC Compiler, 3DSO.ai, and Die-to-Die IP are examples of such tools and IP, to name a few.

Summary

The evolution of multi-die solutions represents a turning point in semiconductor design. With significant advancements in interconnect technology, thermal management, power delivery, and ecosystem development, these architectures are now more feasible, efficient, and cost-effective than ever before. As the demand for high-performance, energy-efficient computing grows, multi-die solutions offer a scalable path forward for the semiconductor industry. Positioned at the intersection of technological innovation, market demand, and economic necessity, multi-die solutions are set to play a pivotal role in shaping the future of computing.

The bold prediction by Synopsys of 50% of new HPC chip designs being multi-die implementations in 2025 looks realistic if not bold enough.

To learn more, visit Synopsys Multi-Die Solution Page.

Also Read:

A Deep Dive into SoC Performance Analysis: What, Why, and How

Synopsys Brings Multi-Die Integration Closer with its 3DIO IP Solution and 3DIC Tools

Enhancing System Reliability with Digital Twins and Silicon Lifecycle Management (SLM)

Share this post via:

Comments

2 Replies to “Will 50% of New High Performance Computing (HPC) Chip Designs be Multi-Die in 2025?”

You must register or log in to view/post comments.