As electric vehicles (EVs) gain widespread adoption, safety, reliability, and efficiency are becoming increasingly important. A crucial component in ensuring these aspects is the power module (PM), which manages the energy flow between the EV battery and the motor. The design of these power modules must not only meet the high-performance demands of modern EVs but also address key challenges such as thermal management, electromagnetic interference, and long-term reliability. To tackle these challenges effectively, an integrated design approach is necessary.

Cadence recently published a whitepaper that addresses this topic and presents an integrated design methodology.

Power Module Design Challenges

As mechanical power demands and fast-charging capabilities increase, power modules must handle higher energy loads, increasing the risk of failures. Poor thermal management, electromigration, warpage, and electromagnetic interference (EMI) are just a few of the challenges that can compromise power module reliability. Additionally, as electric vehicles operate at varying voltages and temperatures, designing compact and efficient power modules that can withstand these conditions is essential to ensure the vehicle’s longevity and safety.

Traditional design processes often fall short because they rely on real-world testing at later stages of development. When issues are discovered at this stage, the cost of fixing them through redesigns can be significant. The new methodology for power module design focuses on early-stage simulations and analyses to avoid these late-cycle issues.

Circuit Analysis and Schematic-Driven Package Design

A reliable power module design starts with circuit analysis, using tools like Cadence PSpice to simulate both digital and analog components. Digital simulations focus on factors like jitter, while analog simulations analyze gain, input impedance, and other performance metrics. By simulating current, voltage, power dissipation, and operating temperatures, designers can ensure reliable thermal performance and preemptively address potential failure points.

These simulations also inform other key analyses, such as warpage and life expectancy estimations through failure modes effects and diagnostic analysis (FMEDA). Ensuring that the schematic-driven package design is correct from the start, through layout versus schematic (LVS) checks, helps streamline the placement of components and connections within the power module. This early-stage precision eliminates potential errors and ensures the reliability of the final design.

Parasitic Extraction and Temperature-Aware Simulation

One of the hidden challenges in power module design is stray inductances, which can cause unwanted electromagnetic radiation and disrupt nearby electronic systems. To address this, the design methodology includes parasitic extraction of bondwires using 3D-quasistatic electromagnetic (EM) simulations. These simulations help identify and mitigate potential risks from electromagnetic interference (EMI), which could otherwise affect the vehicle’s electronic control unit (ECU) and compromise occupant safety.

Parasitic elements are highly temperature-dependent, and their effects on performance can vary significantly with operating temperature and frequency. The methodology incorporates temperature-aware parasitic extraction to account for these variations and ensure accurate calculations for power and temperature. This approach enables the design team to refine the schematic by adjusting discrete components and compensating for parasitic effects, ensuring functional reliability and reducing time-to-market delays.

Thermal Simulation and Electromigration

Effective thermal management is critical for the long-term reliability of power modules in EVs, as these modules can reach temperatures of 130°C or more. Traditional thermal analysis tools often overestimate power levels, leading to over-designed, costlier packages. By tightly coupling electrical and thermal environments in the design phase, the proposed methodology enables a more accurate thermal simulation based on actual operating conditions. This ensures that power modules are designed to handle peak power without being unnecessarily over-engineered, reducing both cost and weight.

High current densities in power modules can lead to electromigration, where metal atoms in interconnects are displaced due to high currents. This can cause functional failures over time. By analyzing current densities in the design phase, the methodology helps designers mitigate these risks and prolong the lifespan of the power module, ensuring long-term vehicle safety.

Mechanical Strain and Warpage Analysis

Mechanical stress can also lead to power module failure, especially when there are large differences in the coefficient of thermal expansion (CTE) between different materials used in the module. This can cause warpage or bending, which leads to component failure. Warpage analysis identifies potential deformation risks and allows designers to implement corrective measures, such as strategic placement of redundant components. This significantly improves the reliability and safety of power modules.

Proposed Integrated Design Methodology

Cadence’s proposed design flow for power modules in EVs focuses on co-optimizing both the die and the package to ensure efficient thermal performance at the design frequency and operating temperature. This integrated approach allows for greater safety and reliability in high-power systems, including EVs, by addressing potential risks early in the design process. By incorporating a “shift left” methodology, which emphasizes identifying and solving problems in the early stages of design, this process minimizes the risk of costly respins and unforeseen failures later in the product cycle.

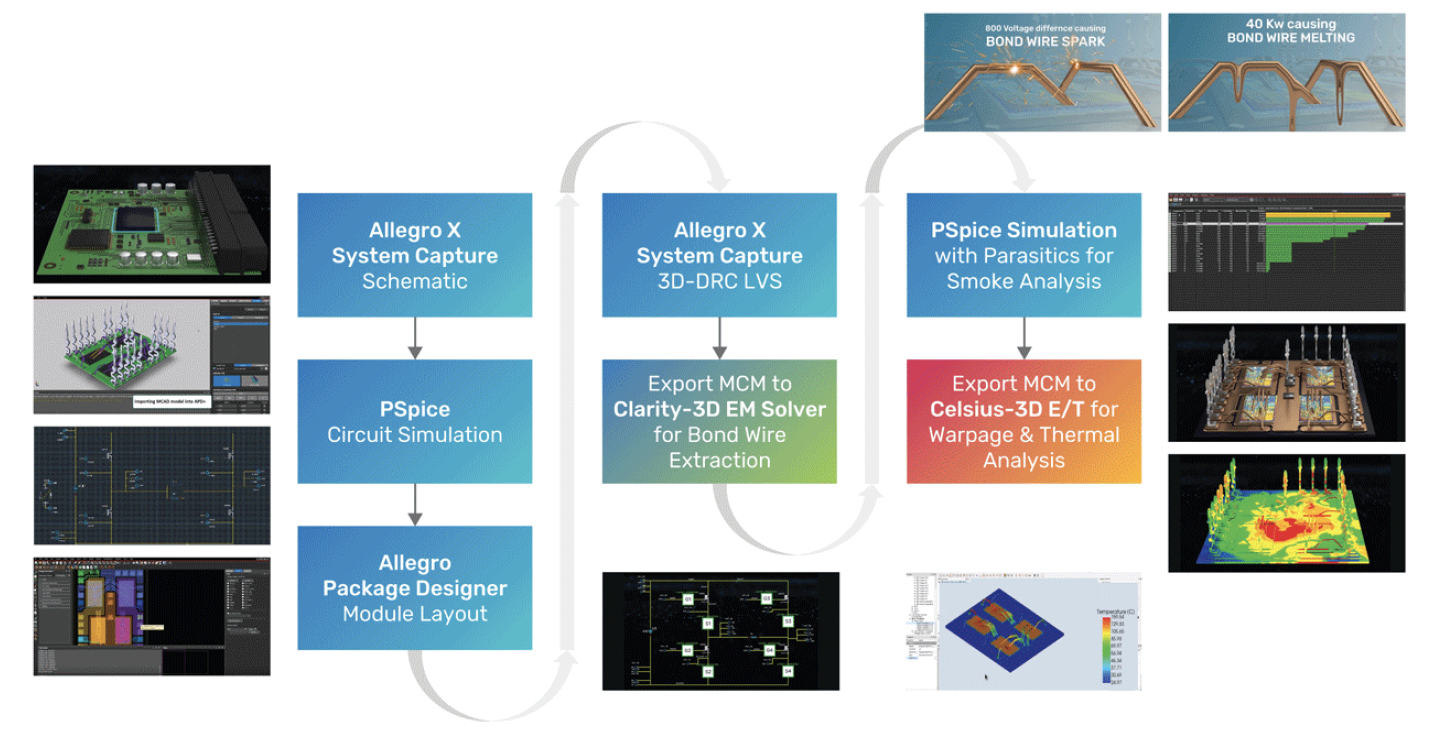

The comprehensive design flow (refer to Figure below), which integrates advanced simulation, parasitic-aware analysis, and thermal management tools, offers a one-stop Cadence solution for power module development. This streamlined process not only accelerates time-to-market but also ensures that EV power modules meet stringent safety and performance requirements.

For more details including the complete analysis of a Press-Fit Full Bridge MOSFET Power Module, access the entire whitepaper here.

Summary

An integrated approach to power module design for electric vehicles not only enhances efficiency but also ensures the safety and reliability of these critical components. By addressing key concerns such as electromigration, parasitic effects, thermal management, and mechanical strain early in the design process, manufacturers can prevent late-stage failures and costly respins. The proposed “shift left” design methodology minimizes risks and reduces development costs, ensuring that power modules deliver reliable performance throughout their operating life. By implementing this methodology, manufacturers can develop power modules that contribute to safer, more efficient, and more reliable electric vehicles for the future.

Also Read:

SI and PI Update from Cadence on Sigrity X

Advanced Audio Tightens Integration to Implementation

Hearing Aids are Embracing Tech, and Cool

Share this post via:

Comments

There are no comments yet.

You must register or log in to view/post comments.