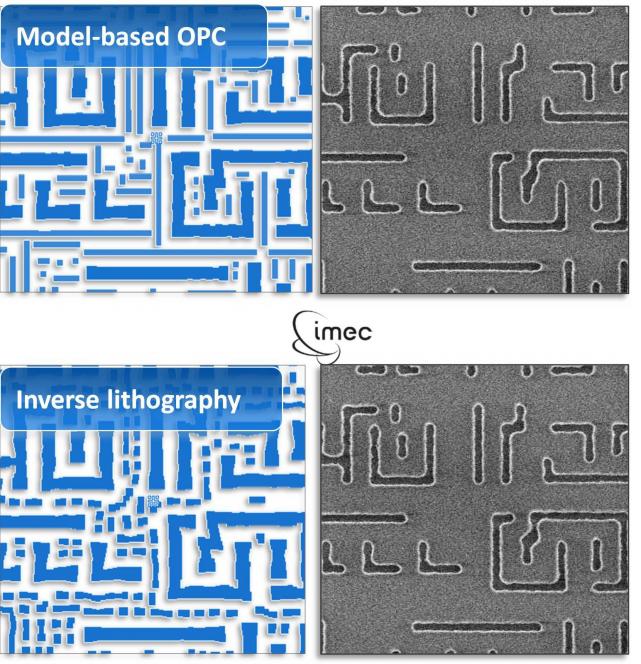

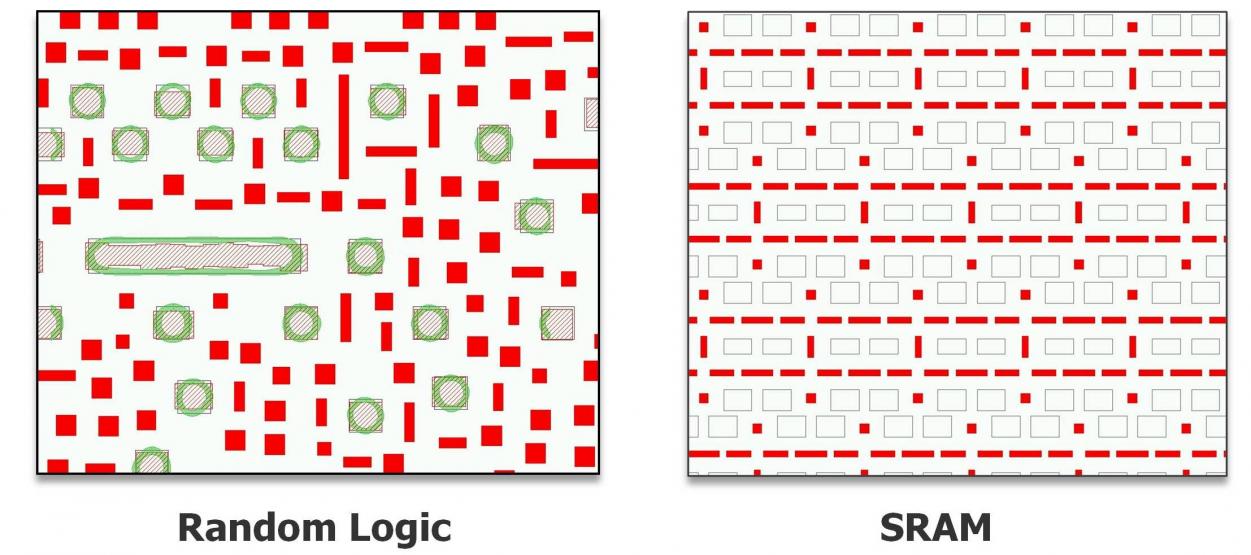

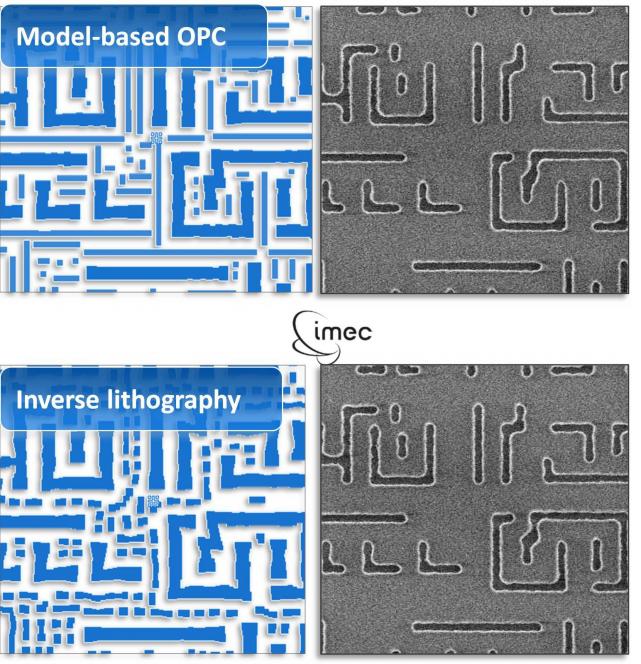

It appears that immersion lithography is now the plan of record for manufacturing ICs at 14nm. How is it possible to use 193nm wavelength light at 14nm? How can we provide the process window to pattern the such tight pitches? The secret lies in computational lithography.  For 20nm, the two key innovations in computational lithography involve enabling double patterning with concurrent OPC, and in improving difficult-to-print layouts with localized in-situ optimization and by using an inverse lithography technique.For 14nm, says Mentor Graphics’ OPC product marketing manager Gandharv Bhatara, computational lithography offers more tools for process window enhancement with better approaches to sub-resolution assist features (SRAFs). SRAFs have been used since the 130nm node for resolution enhancement, but for 14nm, SRAF placement has evolved considerably. In a recent article, Bhatara says that SRAF placement has moved from rules-based to model-based, and describes two new model-based approaches developed in the Mentor OPC tools. One approach uses inverse lithography (ILT) to create the golden reference for a rules-based SRAF placement. This gives superior process window for critical blocks like SRAM, where the rules are relatively easy to develop. The second approach is a true model-based approach, where a model is used to determine which areas on mask would benefit most from SRAFS and also to perform the initial SRAF placement. The model-based approach is particularly useful for random logic designs, where developing rules continues to be challenging.

For 20nm, the two key innovations in computational lithography involve enabling double patterning with concurrent OPC, and in improving difficult-to-print layouts with localized in-situ optimization and by using an inverse lithography technique.For 14nm, says Mentor Graphics’ OPC product marketing manager Gandharv Bhatara, computational lithography offers more tools for process window enhancement with better approaches to sub-resolution assist features (SRAFs). SRAFs have been used since the 130nm node for resolution enhancement, but for 14nm, SRAF placement has evolved considerably. In a recent article, Bhatara says that SRAF placement has moved from rules-based to model-based, and describes two new model-based approaches developed in the Mentor OPC tools. One approach uses inverse lithography (ILT) to create the golden reference for a rules-based SRAF placement. This gives superior process window for critical blocks like SRAM, where the rules are relatively easy to develop. The second approach is a true model-based approach, where a model is used to determine which areas on mask would benefit most from SRAFS and also to perform the initial SRAF placement. The model-based approach is particularly useful for random logic designs, where developing rules continues to be challenging.  Both methods are good, but for different design styles. Bhatara says that for 14nm, combining them into a hybrid approach provides a single, unified SRAF recipe for SRAM (rules-based) and random logic designs (model-based). So if you need the keys to 14nm computational lithography, look for advanced SRAF solutions that provide flexibility, control runtime, and leverage both rules-based and model-based approaches.You can find this and other content on foundry-based IC design and manufacturing at www.mentor.com/solutions/foundry.

Both methods are good, but for different design styles. Bhatara says that for 14nm, combining them into a hybrid approach provides a single, unified SRAF recipe for SRAM (rules-based) and random logic designs (model-based). So if you need the keys to 14nm computational lithography, look for advanced SRAF solutions that provide flexibility, control runtime, and leverage both rules-based and model-based approaches.You can find this and other content on foundry-based IC design and manufacturing at www.mentor.com/solutions/foundry.

Sponsor

Instance

Array

(

[node_name] => Siemens EDA

[node_id] => Array

(

[0] => 2

)

)

Nodes

XF\Mvc\Entity\ArrayCollection Object

(

[entities:protected] => Array

(

[367] => XF\Entity\Node Object

(

[_uniqueEntityId:XF\Mvc\Entity\Entity:private] => 48

[rootClass:protected] => XF\Entity\Node

[_useReplaceInto:protected] =>

[_newValues:protected] => Array

(

)

[_values:protected] => Array

(

[node_id] => 367

[title] => Siemens EDA

[description] =>

[node_name] =>

[node_type_id] => Forum

[parent_node_id] => 355

[display_order] => 380

[display_in_list] => 1

[lft] => 97

[rgt] => 98

[depth] => 2

[style_id] => 0

[effective_style_id] => 4

[breadcrumb_data] => {"385":{"node_id":385,"title":"Companies","depth":0,"lft":13,"node_name":null,"node_type_id":"LinkForum","display_in_list":true},"355":{"node_id":355,"title":"Company Forums","depth":1,"lft":14,"node_name":null,"node_type_id":"Category","display_in_list":true}}

[navigation_id] =>

[effective_navigation_id] =>

)

[_relations:protected] => Array

(

)

[_previousValues:protected] => Array

(

)

[_options:protected] => Array

(

)

[_deleted:protected] =>

[_readOnly:protected] =>

[_writePending:protected] =>

[_writeRunning:protected] =>

[_errors:protected] => Array

(

)

[_whenSaveable:protected] => Array

(

)

[_cascadeSave:protected] => Array

(

)

[_behaviors:protected] =>

)

)

[populated:protected] => 1

)

Threads

XF\Mvc\Entity\ArrayCollection Object

(

[entities:protected] => Array

(

[23114] => ThemeHouse\XPress\XF\Entity\Thread Object

(

[_uniqueEntityId:XF\Mvc\Entity\Entity:private] => 49

[rootClass:protected] => XF\Entity\Thread

[_useReplaceInto:protected] =>

[_newValues:protected] => Array

(

)

[_values:protected] => Array

(

[thread_id] => 23114

[node_id] => 367

[title] => BAC to build next-generation Mono road legal supercar with Siemens Xcelerator

[reply_count] => 0

[view_count] => 78

[user_id] => 25277

[username] => AmandaK

[post_date] => 1751328409

[sticky] => 0

[discussion_state] => visible

[discussion_open] => 1

[discussion_type] => discussion

[first_post_id] => 88097

[first_post_reaction_score] => 0

[first_post_reactions] => []

[last_post_date] => 1751328409

[last_post_id] => 88097

[last_post_user_id] => 25277

[last_post_username] => AmandaK

[prefix_id] => 0

[tags] => []

[custom_fields] => []

[vote_score] => 0

[vote_count] => 0

[type_data] => []

)

[_relations:protected] => Array

(

[Forum] => XF\Entity\Forum Object

(

[_uniqueEntityId:XF\Mvc\Entity\Entity:private] => 70

[rootClass:protected] => XF\Entity\Forum

[_useReplaceInto:protected] =>

[_newValues:protected] => Array

(

)

[_values:protected] => Array

(

[node_id] => 367

[discussion_count] => 322

[message_count] => 324

[last_post_id] => 88097

[last_post_date] => 1751328409

[last_post_user_id] => 25277

[last_post_username] => AmandaK

[last_thread_id] => 23114

[last_thread_title] => BAC to build next-generation Mono road legal supercar with Siemens Xcelerator

[last_thread_prefix_id] => 0

[moderate_threads] => 1

[moderate_replies] => 1

[allow_posting] => 1

[count_messages] => 1

[find_new] => 1

[allow_index] => allow

[index_criteria] =>

[field_cache] => []

[prefix_cache] => []

[prompt_cache] => []

[default_prefix_id] => 0

[default_sort_order] => last_post_date

[default_sort_direction] => desc

[list_date_limit_days] => 0

[require_prefix] => 0

[allowed_watch_notifications] => all

[min_tags] => 0

[forum_type_id] => discussion

[type_config] => {"allowed_thread_types":["poll"],"allow_answer_voting":false,"allow_answer_downvote":false}

)

[_relations:protected] => Array

(

[Node] => XF\Entity\Node Object

(

[_uniqueEntityId:XF\Mvc\Entity\Entity:private] => 48

[rootClass:protected] => XF\Entity\Node

[_useReplaceInto:protected] =>

[_newValues:protected] => Array

(

)

[_values:protected] => Array

(

[node_id] => 367

[title] => Siemens EDA

[description] =>

[node_name] =>

[node_type_id] => Forum

[parent_node_id] => 355

[display_order] => 380

[display_in_list] => 1

[lft] => 97

[rgt] => 98

[depth] => 2

[style_id] => 0

[effective_style_id] => 4

[breadcrumb_data] => {"385":{"node_id":385,"title":"Companies","depth":0,"lft":13,"node_name":null,"node_type_id":"LinkForum","display_in_list":true},"355":{"node_id":355,"title":"Company Forums","depth":1,"lft":14,"node_name":null,"node_type_id":"Category","display_in_list":true}}

[navigation_id] =>

[effective_navigation_id] =>

)

[_relations:protected] => Array

(

)

[_previousValues:protected] => Array

(

)

[_options:protected] => Array

(

)

[_deleted:protected] =>

[_readOnly:protected] =>

[_writePending:protected] =>

[_writeRunning:protected] =>

[_errors:protected] => Array

(

)

[_whenSaveable:protected] => Array

(

)

[_cascadeSave:protected] => Array

(

)

[_behaviors:protected] =>

)

)

[_previousValues:protected] => Array

(

)

[_options:protected] => Array

(

)

[_deleted:protected] =>

[_readOnly:protected] =>

[_writePending:protected] =>

[_writeRunning:protected] =>

[_errors:protected] => Array

(

)

[_whenSaveable:protected] => Array

(

)

[_cascadeSave:protected] => Array

(

)

[_behaviors:protected] =>

)

)

[_previousValues:protected] => Array

(

)

[_options:protected] => Array

(

)

[_deleted:protected] =>

[_readOnly:protected] =>

[_writePending:protected] =>

[_writeRunning:protected] =>

[_errors:protected] => Array

(

)

[_whenSaveable:protected] => Array

(

)

[_cascadeSave:protected] => Array

(

)

[_behaviors:protected] =>

)

[23078] => ThemeHouse\XPress\XF\Entity\Thread Object

(

[_uniqueEntityId:XF\Mvc\Entity\Entity:private] => 50

[rootClass:protected] => XF\Entity\Thread

[_useReplaceInto:protected] =>

[_newValues:protected] => Array

(

)

[_values:protected] => Array

(

[thread_id] => 23078

[node_id] => 367

[title] => Siemens streamlines design and analysis of complex, heterogeneously integrated 3D ICs

[reply_count] => 0

[view_count] => 366

[user_id] => 25277

[username] => AmandaK

[post_date] => 1750778973

[sticky] => 0

[discussion_state] => visible

[discussion_open] => 1

[discussion_type] => discussion

[first_post_id] => 87882

[first_post_reaction_score] => 0

[first_post_reactions] => []

[last_post_date] => 1750778973

[last_post_id] => 87882

[last_post_user_id] => 25277

[last_post_username] => AmandaK

[prefix_id] => 0

[tags] => []

[custom_fields] => []

[vote_score] => 0

[vote_count] => 0

[type_data] => []

)

[_relations:protected] => Array

(

[Forum] => XF\Entity\Forum Object

(

[_uniqueEntityId:XF\Mvc\Entity\Entity:private] => 70

[rootClass:protected] => XF\Entity\Forum

[_useReplaceInto:protected] =>

[_newValues:protected] => Array

(

)

[_values:protected] => Array

(

[node_id] => 367

[discussion_count] => 322

[message_count] => 324

[last_post_id] => 88097

[last_post_date] => 1751328409

[last_post_user_id] => 25277

[last_post_username] => AmandaK

[last_thread_id] => 23114

[last_thread_title] => BAC to build next-generation Mono road legal supercar with Siemens Xcelerator

[last_thread_prefix_id] => 0

[moderate_threads] => 1

[moderate_replies] => 1

[allow_posting] => 1

[count_messages] => 1

[find_new] => 1

[allow_index] => allow

[index_criteria] =>

[field_cache] => []

[prefix_cache] => []

[prompt_cache] => []

[default_prefix_id] => 0

[default_sort_order] => last_post_date

[default_sort_direction] => desc

[list_date_limit_days] => 0

[require_prefix] => 0

[allowed_watch_notifications] => all

[min_tags] => 0

[forum_type_id] => discussion

[type_config] => {"allowed_thread_types":["poll"],"allow_answer_voting":false,"allow_answer_downvote":false}

)

[_relations:protected] => Array

(

[Node] => XF\Entity\Node Object

(

[_uniqueEntityId:XF\Mvc\Entity\Entity:private] => 48

[rootClass:protected] => XF\Entity\Node

[_useReplaceInto:protected] =>

[_newValues:protected] => Array

(

)

[_values:protected] => Array

(

[node_id] => 367

[title] => Siemens EDA

[description] =>

[node_name] =>

[node_type_id] => Forum

[parent_node_id] => 355

[display_order] => 380

[display_in_list] => 1

[lft] => 97

[rgt] => 98

[depth] => 2

[style_id] => 0

[effective_style_id] => 4

[breadcrumb_data] => {"385":{"node_id":385,"title":"Companies","depth":0,"lft":13,"node_name":null,"node_type_id":"LinkForum","display_in_list":true},"355":{"node_id":355,"title":"Company Forums","depth":1,"lft":14,"node_name":null,"node_type_id":"Category","display_in_list":true}}

[navigation_id] =>

[effective_navigation_id] =>

)

[_relations:protected] => Array

(

)

[_previousValues:protected] => Array

(

)

[_options:protected] => Array

(

)

[_deleted:protected] =>

[_readOnly:protected] =>

[_writePending:protected] =>

[_writeRunning:protected] =>

[_errors:protected] => Array

(

)

[_whenSaveable:protected] => Array

(

)

[_cascadeSave:protected] => Array

(

)

[_behaviors:protected] =>

)

)

[_previousValues:protected] => Array

(

)

[_options:protected] => Array

(

)

[_deleted:protected] =>

[_readOnly:protected] =>

[_writePending:protected] =>

[_writeRunning:protected] =>

[_errors:protected] => Array

(

)

[_whenSaveable:protected] => Array

(

)

[_cascadeSave:protected] => Array

(

)

[_behaviors:protected] =>

)

)

[_previousValues:protected] => Array

(

)

[_options:protected] => Array

(

)

[_deleted:protected] =>

[_readOnly:protected] =>

[_writePending:protected] =>

[_writeRunning:protected] =>

[_errors:protected] => Array

(

)

[_whenSaveable:protected] => Array

(

)

[_cascadeSave:protected] => Array

(

)

[_behaviors:protected] =>

)

[23077] => ThemeHouse\XPress\XF\Entity\Thread Object

(

[_uniqueEntityId:XF\Mvc\Entity\Entity:private] => 51

[rootClass:protected] => XF\Entity\Thread

[_useReplaceInto:protected] =>

[_newValues:protected] => Array

(

)

[_values:protected] => Array

(

[thread_id] => 23077

[node_id] => 367

[title] => Siemens turbocharges semiconductor and PCB design portfolio with generative and agentic AI

[reply_count] => 0

[view_count] => 388

[user_id] => 25277

[username] => AmandaK

[post_date] => 1750778919

[sticky] => 0

[discussion_state] => visible

[discussion_open] => 1

[discussion_type] => discussion

[first_post_id] => 87881

[first_post_reaction_score] => 0

[first_post_reactions] => []

[last_post_date] => 1750778919

[last_post_id] => 87881

[last_post_user_id] => 25277

[last_post_username] => AmandaK

[prefix_id] => 0

[tags] => []

[custom_fields] => []

[vote_score] => 0

[vote_count] => 0

[type_data] => []

)

[_relations:protected] => Array

(

[Forum] => XF\Entity\Forum Object

(

[_uniqueEntityId:XF\Mvc\Entity\Entity:private] => 70

[rootClass:protected] => XF\Entity\Forum

[_useReplaceInto:protected] =>

[_newValues:protected] => Array

(

)

[_values:protected] => Array

(

[node_id] => 367

[discussion_count] => 322

[message_count] => 324

[last_post_id] => 88097

[last_post_date] => 1751328409

[last_post_user_id] => 25277

[last_post_username] => AmandaK

[last_thread_id] => 23114

[last_thread_title] => BAC to build next-generation Mono road legal supercar with Siemens Xcelerator

[last_thread_prefix_id] => 0

[moderate_threads] => 1

[moderate_replies] => 1

[allow_posting] => 1

[count_messages] => 1

[find_new] => 1

[allow_index] => allow

[index_criteria] =>

[field_cache] => []

[prefix_cache] => []

[prompt_cache] => []

[default_prefix_id] => 0

[default_sort_order] => last_post_date

[default_sort_direction] => desc

[list_date_limit_days] => 0

[require_prefix] => 0

[allowed_watch_notifications] => all

[min_tags] => 0

[forum_type_id] => discussion

[type_config] => {"allowed_thread_types":["poll"],"allow_answer_voting":false,"allow_answer_downvote":false}

)

[_relations:protected] => Array

(

[Node] => XF\Entity\Node Object

(

[_uniqueEntityId:XF\Mvc\Entity\Entity:private] => 48

[rootClass:protected] => XF\Entity\Node

[_useReplaceInto:protected] =>

[_newValues:protected] => Array

(

)

[_values:protected] => Array

(

[node_id] => 367

[title] => Siemens EDA

[description] =>

[node_name] =>

[node_type_id] => Forum

[parent_node_id] => 355

[display_order] => 380

[display_in_list] => 1

[lft] => 97

[rgt] => 98

[depth] => 2

[style_id] => 0

[effective_style_id] => 4

[breadcrumb_data] => {"385":{"node_id":385,"title":"Companies","depth":0,"lft":13,"node_name":null,"node_type_id":"LinkForum","display_in_list":true},"355":{"node_id":355,"title":"Company Forums","depth":1,"lft":14,"node_name":null,"node_type_id":"Category","display_in_list":true}}

[navigation_id] =>

[effective_navigation_id] =>

)

[_relations:protected] => Array

(

)

[_previousValues:protected] => Array

(

)

[_options:protected] => Array

(

)

[_deleted:protected] =>

[_readOnly:protected] =>

[_writePending:protected] =>

[_writeRunning:protected] =>

[_errors:protected] => Array

(

)

[_whenSaveable:protected] => Array

(

)

[_cascadeSave:protected] => Array

(

)

[_behaviors:protected] =>

)

)

[_previousValues:protected] => Array

(

)

[_options:protected] => Array

(

)

[_deleted:protected] =>

[_readOnly:protected] =>

[_writePending:protected] =>

[_writeRunning:protected] =>

[_errors:protected] => Array

(

)

[_whenSaveable:protected] => Array

(

)

[_cascadeSave:protected] => Array

(

)

[_behaviors:protected] =>

)

)

[_previousValues:protected] => Array

(

)

[_options:protected] => Array

(

)

[_deleted:protected] =>

[_readOnly:protected] =>

[_writePending:protected] =>

[_writeRunning:protected] =>

[_errors:protected] => Array

(

)

[_whenSaveable:protected] => Array

(

)

[_cascadeSave:protected] => Array

(

)

[_behaviors:protected] =>

)

[23076] => ThemeHouse\XPress\XF\Entity\Thread Object

(

[_uniqueEntityId:XF\Mvc\Entity\Entity:private] => 52

[rootClass:protected] => XF\Entity\Thread

[_useReplaceInto:protected] =>

[_newValues:protected] => Array

(

)

[_values:protected] => Array

(

[thread_id] => 23076

[node_id] => 367

[title] => Rapidus announces collaboration with Siemens for 2nm semiconductor design

[reply_count] => 0

[view_count] => 188

[user_id] => 25277

[username] => AmandaK

[post_date] => 1750778848

[sticky] => 0

[discussion_state] => visible

[discussion_open] => 1

[discussion_type] => discussion

[first_post_id] => 87880

[first_post_reaction_score] => 0

[first_post_reactions] => []

[last_post_date] => 1750778848

[last_post_id] => 87880

[last_post_user_id] => 25277

[last_post_username] => AmandaK

[prefix_id] => 0

[tags] => []

[custom_fields] => []

[vote_score] => 0

[vote_count] => 0

[type_data] => []

)

[_relations:protected] => Array

(

[Forum] => XF\Entity\Forum Object

(

[_uniqueEntityId:XF\Mvc\Entity\Entity:private] => 70

[rootClass:protected] => XF\Entity\Forum

[_useReplaceInto:protected] =>

[_newValues:protected] => Array

(

)

[_values:protected] => Array

(

[node_id] => 367

[discussion_count] => 322

[message_count] => 324

[last_post_id] => 88097

[last_post_date] => 1751328409

[last_post_user_id] => 25277

[last_post_username] => AmandaK

[last_thread_id] => 23114

[last_thread_title] => BAC to build next-generation Mono road legal supercar with Siemens Xcelerator

[last_thread_prefix_id] => 0

[moderate_threads] => 1

[moderate_replies] => 1

[allow_posting] => 1

[count_messages] => 1

[find_new] => 1

[allow_index] => allow

[index_criteria] =>

[field_cache] => []

[prefix_cache] => []

[prompt_cache] => []

[default_prefix_id] => 0

[default_sort_order] => last_post_date

[default_sort_direction] => desc

[list_date_limit_days] => 0

[require_prefix] => 0

[allowed_watch_notifications] => all

[min_tags] => 0

[forum_type_id] => discussion

[type_config] => {"allowed_thread_types":["poll"],"allow_answer_voting":false,"allow_answer_downvote":false}

)

[_relations:protected] => Array

(

[Node] => XF\Entity\Node Object

(

[_uniqueEntityId:XF\Mvc\Entity\Entity:private] => 48

[rootClass:protected] => XF\Entity\Node

[_useReplaceInto:protected] =>

[_newValues:protected] => Array

(

)

[_values:protected] => Array

(

[node_id] => 367

[title] => Siemens EDA

[description] =>

[node_name] =>

[node_type_id] => Forum

[parent_node_id] => 355

[display_order] => 380

[display_in_list] => 1

[lft] => 97

[rgt] => 98

[depth] => 2

[style_id] => 0

[effective_style_id] => 4

[breadcrumb_data] => {"385":{"node_id":385,"title":"Companies","depth":0,"lft":13,"node_name":null,"node_type_id":"LinkForum","display_in_list":true},"355":{"node_id":355,"title":"Company Forums","depth":1,"lft":14,"node_name":null,"node_type_id":"Category","display_in_list":true}}

[navigation_id] =>

[effective_navigation_id] =>

)

[_relations:protected] => Array

(

)

[_previousValues:protected] => Array

(

)

[_options:protected] => Array

(

)

[_deleted:protected] =>

[_readOnly:protected] =>

[_writePending:protected] =>

[_writeRunning:protected] =>

[_errors:protected] => Array

(

)

[_whenSaveable:protected] => Array

(

)

[_cascadeSave:protected] => Array

(

)

[_behaviors:protected] =>

)

)

[_previousValues:protected] => Array

(

)

[_options:protected] => Array

(

)

[_deleted:protected] =>

[_readOnly:protected] =>

[_writePending:protected] =>

[_writeRunning:protected] =>

[_errors:protected] => Array

(

)

[_whenSaveable:protected] => Array

(

)

[_cascadeSave:protected] => Array

(

)

[_behaviors:protected] =>

)

)

[_previousValues:protected] => Array

(

)

[_options:protected] => Array

(

)

[_deleted:protected] =>

[_readOnly:protected] =>

[_writePending:protected] =>

[_writeRunning:protected] =>

[_errors:protected] => Array

(

)

[_whenSaveable:protected] => Array

(

)

[_cascadeSave:protected] => Array

(

)

[_behaviors:protected] =>

)

[23042] => ThemeHouse\XPress\XF\Entity\Thread Object

(

[_uniqueEntityId:XF\Mvc\Entity\Entity:private] => 53

[rootClass:protected] => XF\Entity\Thread

[_useReplaceInto:protected] =>

[_newValues:protected] => Array

(

)

[_values:protected] => Array

(

[thread_id] => 23042

[node_id] => 367

[title] => Siemens showcases the power of digital transformation at Paris Air Show

[reply_count] => 0

[view_count] => 485

[user_id] => 25277

[username] => AmandaK

[post_date] => 1750111116

[sticky] => 0

[discussion_state] => visible

[discussion_open] => 1

[discussion_type] => discussion

[first_post_id] => 87586

[first_post_reaction_score] => 0

[first_post_reactions] => []

[last_post_date] => 1750111116

[last_post_id] => 87586

[last_post_user_id] => 25277

[last_post_username] => AmandaK

[prefix_id] => 0

[tags] => []

[custom_fields] => []

[vote_score] => 0

[vote_count] => 0

[type_data] => []

)

[_relations:protected] => Array

(

[Forum] => XF\Entity\Forum Object

(

[_uniqueEntityId:XF\Mvc\Entity\Entity:private] => 70

[rootClass:protected] => XF\Entity\Forum

[_useReplaceInto:protected] =>

[_newValues:protected] => Array

(

)

[_values:protected] => Array

(

[node_id] => 367

[discussion_count] => 322

[message_count] => 324

[last_post_id] => 88097

[last_post_date] => 1751328409

[last_post_user_id] => 25277

[last_post_username] => AmandaK

[last_thread_id] => 23114

[last_thread_title] => BAC to build next-generation Mono road legal supercar with Siemens Xcelerator

[last_thread_prefix_id] => 0

[moderate_threads] => 1

[moderate_replies] => 1

[allow_posting] => 1

[count_messages] => 1

[find_new] => 1

[allow_index] => allow

[index_criteria] =>

[field_cache] => []

[prefix_cache] => []

[prompt_cache] => []

[default_prefix_id] => 0

[default_sort_order] => last_post_date

[default_sort_direction] => desc

[list_date_limit_days] => 0

[require_prefix] => 0

[allowed_watch_notifications] => all

[min_tags] => 0

[forum_type_id] => discussion

[type_config] => {"allowed_thread_types":["poll"],"allow_answer_voting":false,"allow_answer_downvote":false}

)

[_relations:protected] => Array

(

[Node] => XF\Entity\Node Object

(

[_uniqueEntityId:XF\Mvc\Entity\Entity:private] => 48

[rootClass:protected] => XF\Entity\Node

[_useReplaceInto:protected] =>

[_newValues:protected] => Array

(

)

[_values:protected] => Array

(

[node_id] => 367

[title] => Siemens EDA

[description] =>

[node_name] =>

[node_type_id] => Forum

[parent_node_id] => 355

[display_order] => 380

[display_in_list] => 1

[lft] => 97

[rgt] => 98

[depth] => 2

[style_id] => 0

[effective_style_id] => 4

[breadcrumb_data] => {"385":{"node_id":385,"title":"Companies","depth":0,"lft":13,"node_name":null,"node_type_id":"LinkForum","display_in_list":true},"355":{"node_id":355,"title":"Company Forums","depth":1,"lft":14,"node_name":null,"node_type_id":"Category","display_in_list":true}}

[navigation_id] =>

[effective_navigation_id] =>

)

[_relations:protected] => Array

(

)

[_previousValues:protected] => Array

(

)

[_options:protected] => Array

(

)

[_deleted:protected] =>

[_readOnly:protected] =>

[_writePending:protected] =>

[_writeRunning:protected] =>

[_errors:protected] => Array

(

)

[_whenSaveable:protected] => Array

(

)

[_cascadeSave:protected] => Array

(

)

[_behaviors:protected] =>

)

)

[_previousValues:protected] => Array

(

)

[_options:protected] => Array

(

)

[_deleted:protected] =>

[_readOnly:protected] =>

[_writePending:protected] =>

[_writeRunning:protected] =>

[_errors:protected] => Array

(

)

[_whenSaveable:protected] => Array

(

)

[_cascadeSave:protected] => Array

(

)

[_behaviors:protected] =>

)

)

[_previousValues:protected] => Array

(

)

[_options:protected] => Array

(

)

[_deleted:protected] =>

[_readOnly:protected] =>

[_writePending:protected] =>

[_writeRunning:protected] =>

[_errors:protected] => Array

(

)

[_whenSaveable:protected] => Array

(

)

[_cascadeSave:protected] => Array

(

)

[_behaviors:protected] =>

)

[23041] => ThemeHouse\XPress\XF\Entity\Thread Object

(

[_uniqueEntityId:XF\Mvc\Entity\Entity:private] => 54

[rootClass:protected] => XF\Entity\Thread

[_useReplaceInto:protected] =>

[_newValues:protected] => Array

(

)

[_values:protected] => Array

(

[thread_id] => 23041

[node_id] => 367

[title] => Siemens collaborates with Samsung Foundry on advanced node product certifications and EDA innovation

[reply_count] => 0

[view_count] => 487

[user_id] => 25277

[username] => AmandaK

[post_date] => 1750111064

[sticky] => 0

[discussion_state] => visible

[discussion_open] => 1

[discussion_type] => discussion

[first_post_id] => 87585

[first_post_reaction_score] => 0

[first_post_reactions] => []

[last_post_date] => 1750111064

[last_post_id] => 87585

[last_post_user_id] => 25277

[last_post_username] => AmandaK

[prefix_id] => 0

[tags] => []

[custom_fields] => []

[vote_score] => 0

[vote_count] => 0

[type_data] => []

)

[_relations:protected] => Array

(

[Forum] => XF\Entity\Forum Object

(

[_uniqueEntityId:XF\Mvc\Entity\Entity:private] => 70

[rootClass:protected] => XF\Entity\Forum

[_useReplaceInto:protected] =>

[_newValues:protected] => Array

(

)

[_values:protected] => Array

(

[node_id] => 367

[discussion_count] => 322

[message_count] => 324

[last_post_id] => 88097

[last_post_date] => 1751328409

[last_post_user_id] => 25277

[last_post_username] => AmandaK

[last_thread_id] => 23114

[last_thread_title] => BAC to build next-generation Mono road legal supercar with Siemens Xcelerator

[last_thread_prefix_id] => 0

[moderate_threads] => 1

[moderate_replies] => 1

[allow_posting] => 1

[count_messages] => 1

[find_new] => 1

[allow_index] => allow

[index_criteria] =>

[field_cache] => []

[prefix_cache] => []

[prompt_cache] => []

[default_prefix_id] => 0

[default_sort_order] => last_post_date

[default_sort_direction] => desc

[list_date_limit_days] => 0

[require_prefix] => 0

[allowed_watch_notifications] => all

[min_tags] => 0

[forum_type_id] => discussion

[type_config] => {"allowed_thread_types":["poll"],"allow_answer_voting":false,"allow_answer_downvote":false}

)

[_relations:protected] => Array

(

[Node] => XF\Entity\Node Object

(

[_uniqueEntityId:XF\Mvc\Entity\Entity:private] => 48

[rootClass:protected] => XF\Entity\Node

[_useReplaceInto:protected] =>

[_newValues:protected] => Array

(

)

[_values:protected] => Array

(

[node_id] => 367

[title] => Siemens EDA

[description] =>

[node_name] =>

[node_type_id] => Forum

[parent_node_id] => 355

[display_order] => 380

[display_in_list] => 1

[lft] => 97

[rgt] => 98

[depth] => 2

[style_id] => 0

[effective_style_id] => 4

[breadcrumb_data] => {"385":{"node_id":385,"title":"Companies","depth":0,"lft":13,"node_name":null,"node_type_id":"LinkForum","display_in_list":true},"355":{"node_id":355,"title":"Company Forums","depth":1,"lft":14,"node_name":null,"node_type_id":"Category","display_in_list":true}}

[navigation_id] =>

[effective_navigation_id] =>

)

[_relations:protected] => Array

(

)

[_previousValues:protected] => Array

(

)

[_options:protected] => Array

(

)

[_deleted:protected] =>

[_readOnly:protected] =>

[_writePending:protected] =>

[_writeRunning:protected] =>

[_errors:protected] => Array

(

)

[_whenSaveable:protected] => Array

(

)

[_cascadeSave:protected] => Array

(

)

[_behaviors:protected] =>

)

)

[_previousValues:protected] => Array

(

)

[_options:protected] => Array

(

)

[_deleted:protected] =>

[_readOnly:protected] =>

[_writePending:protected] =>

[_writeRunning:protected] =>

[_errors:protected] => Array

(

)

[_whenSaveable:protected] => Array

(

)

[_cascadeSave:protected] => Array

(

)

[_behaviors:protected] =>

)

)

[_previousValues:protected] => Array

(

)

[_options:protected] => Array

(

)

[_deleted:protected] =>

[_readOnly:protected] =>

[_writePending:protected] =>

[_writeRunning:protected] =>

[_errors:protected] => Array

(

)

[_whenSaveable:protected] => Array

(

)

[_cascadeSave:protected] => Array

(

)

[_behaviors:protected] =>

)

[23022] => ThemeHouse\XPress\XF\Entity\Thread Object

(

[_uniqueEntityId:XF\Mvc\Entity\Entity:private] => 55

[rootClass:protected] => XF\Entity\Thread

[_useReplaceInto:protected] =>

[_newValues:protected] => Array

(

)

[_values:protected] => Array

(

[thread_id] => 23022

[node_id] => 367

[title] => Siemens - Calibre seminar at DAC

[reply_count] => 0

[view_count] => 359

[user_id] => 25277

[username] => AmandaK

[post_date] => 1749757921

[sticky] => 0

[discussion_state] => visible

[discussion_open] => 1

[discussion_type] => discussion

[first_post_id] => 87467

[first_post_reaction_score] => 0

[first_post_reactions] => []

[last_post_date] => 1749757921

[last_post_id] => 87467

[last_post_user_id] => 25277

[last_post_username] => AmandaK

[prefix_id] => 0

[tags] => []

[custom_fields] => []

[vote_score] => 0

[vote_count] => 0

[type_data] => []

)

[_relations:protected] => Array

(

[Forum] => XF\Entity\Forum Object

(

[_uniqueEntityId:XF\Mvc\Entity\Entity:private] => 70

[rootClass:protected] => XF\Entity\Forum

[_useReplaceInto:protected] =>

[_newValues:protected] => Array

(

)

[_values:protected] => Array

(

[node_id] => 367

[discussion_count] => 322

[message_count] => 324

[last_post_id] => 88097

[last_post_date] => 1751328409

[last_post_user_id] => 25277

[last_post_username] => AmandaK

[last_thread_id] => 23114

[last_thread_title] => BAC to build next-generation Mono road legal supercar with Siemens Xcelerator

[last_thread_prefix_id] => 0

[moderate_threads] => 1

[moderate_replies] => 1

[allow_posting] => 1

[count_messages] => 1

[find_new] => 1

[allow_index] => allow

[index_criteria] =>

[field_cache] => []

[prefix_cache] => []

[prompt_cache] => []

[default_prefix_id] => 0

[default_sort_order] => last_post_date

[default_sort_direction] => desc

[list_date_limit_days] => 0

[require_prefix] => 0

[allowed_watch_notifications] => all

[min_tags] => 0

[forum_type_id] => discussion

[type_config] => {"allowed_thread_types":["poll"],"allow_answer_voting":false,"allow_answer_downvote":false}

)

[_relations:protected] => Array

(

[Node] => XF\Entity\Node Object

(

[_uniqueEntityId:XF\Mvc\Entity\Entity:private] => 48

[rootClass:protected] => XF\Entity\Node

[_useReplaceInto:protected] =>

[_newValues:protected] => Array

(

)

[_values:protected] => Array

(

[node_id] => 367

[title] => Siemens EDA

[description] =>

[node_name] =>

[node_type_id] => Forum

[parent_node_id] => 355

[display_order] => 380

[display_in_list] => 1

[lft] => 97

[rgt] => 98

[depth] => 2

[style_id] => 0

[effective_style_id] => 4

[breadcrumb_data] => {"385":{"node_id":385,"title":"Companies","depth":0,"lft":13,"node_name":null,"node_type_id":"LinkForum","display_in_list":true},"355":{"node_id":355,"title":"Company Forums","depth":1,"lft":14,"node_name":null,"node_type_id":"Category","display_in_list":true}}

[navigation_id] =>

[effective_navigation_id] =>

)

[_relations:protected] => Array

(

)

[_previousValues:protected] => Array

(

)

[_options:protected] => Array

(

)

[_deleted:protected] =>

[_readOnly:protected] =>

[_writePending:protected] =>

[_writeRunning:protected] =>

[_errors:protected] => Array

(

)

[_whenSaveable:protected] => Array

(

)

[_cascadeSave:protected] => Array

(

)

[_behaviors:protected] =>

)

)

[_previousValues:protected] => Array

(

)

[_options:protected] => Array

(

)

[_deleted:protected] =>

[_readOnly:protected] =>

[_writePending:protected] =>

[_writeRunning:protected] =>

[_errors:protected] => Array

(

)

[_whenSaveable:protected] => Array

(

)

[_cascadeSave:protected] => Array

(

)

[_behaviors:protected] =>

)

)

[_previousValues:protected] => Array

(

)

[_options:protected] => Array

(

)

[_deleted:protected] =>

[_readOnly:protected] =>

[_writePending:protected] =>

[_writeRunning:protected] =>

[_errors:protected] => Array

(

)

[_whenSaveable:protected] => Array

(

)

[_cascadeSave:protected] => Array

(

)

[_behaviors:protected] =>

)

[23021] => ThemeHouse\XPress\XF\Entity\Thread Object

(

[_uniqueEntityId:XF\Mvc\Entity\Entity:private] => 56

[rootClass:protected] => XF\Entity\Thread

[_useReplaceInto:protected] =>

[_newValues:protected] => Array

(

)

[_values:protected] => Array

(

[thread_id] => 23021

[node_id] => 367

[title] => Cimolai Technology drives heavy equipment industry innovation with Siemens Xcelerator

[reply_count] => 0

[view_count] => 255

[user_id] => 25277

[username] => AmandaK

[post_date] => 1749757638

[sticky] => 0

[discussion_state] => visible

[discussion_open] => 1

[discussion_type] => discussion

[first_post_id] => 87466

[first_post_reaction_score] => 0

[first_post_reactions] => []

[last_post_date] => 1749757638

[last_post_id] => 87466

[last_post_user_id] => 25277

[last_post_username] => AmandaK

[prefix_id] => 0

[tags] => []

[custom_fields] => []

[vote_score] => 0

[vote_count] => 0

[type_data] => []

)

[_relations:protected] => Array

(

[Forum] => XF\Entity\Forum Object

(

[_uniqueEntityId:XF\Mvc\Entity\Entity:private] => 70

[rootClass:protected] => XF\Entity\Forum

[_useReplaceInto:protected] =>

[_newValues:protected] => Array

(

)

[_values:protected] => Array

(

[node_id] => 367

[discussion_count] => 322

[message_count] => 324

[last_post_id] => 88097

[last_post_date] => 1751328409

[last_post_user_id] => 25277

[last_post_username] => AmandaK

[last_thread_id] => 23114

[last_thread_title] => BAC to build next-generation Mono road legal supercar with Siemens Xcelerator

[last_thread_prefix_id] => 0

[moderate_threads] => 1

[moderate_replies] => 1

[allow_posting] => 1

[count_messages] => 1

[find_new] => 1

[allow_index] => allow

[index_criteria] =>

[field_cache] => []

[prefix_cache] => []

[prompt_cache] => []

[default_prefix_id] => 0

[default_sort_order] => last_post_date

[default_sort_direction] => desc

[list_date_limit_days] => 0

[require_prefix] => 0

[allowed_watch_notifications] => all

[min_tags] => 0

[forum_type_id] => discussion

[type_config] => {"allowed_thread_types":["poll"],"allow_answer_voting":false,"allow_answer_downvote":false}

)

[_relations:protected] => Array

(

[Node] => XF\Entity\Node Object

(

[_uniqueEntityId:XF\Mvc\Entity\Entity:private] => 48

[rootClass:protected] => XF\Entity\Node

[_useReplaceInto:protected] =>

[_newValues:protected] => Array

(

)

[_values:protected] => Array

(

[node_id] => 367

[title] => Siemens EDA

[description] =>

[node_name] =>

[node_type_id] => Forum

[parent_node_id] => 355

[display_order] => 380

[display_in_list] => 1

[lft] => 97

[rgt] => 98

[depth] => 2

[style_id] => 0

[effective_style_id] => 4

[breadcrumb_data] => {"385":{"node_id":385,"title":"Companies","depth":0,"lft":13,"node_name":null,"node_type_id":"LinkForum","display_in_list":true},"355":{"node_id":355,"title":"Company Forums","depth":1,"lft":14,"node_name":null,"node_type_id":"Category","display_in_list":true}}

[navigation_id] =>

[effective_navigation_id] =>

)

[_relations:protected] => Array

(

)

[_previousValues:protected] => Array

(

)

[_options:protected] => Array

(

)

[_deleted:protected] =>

[_readOnly:protected] =>

[_writePending:protected] =>

[_writeRunning:protected] =>

[_errors:protected] => Array

(

)

[_whenSaveable:protected] => Array

(

)

[_cascadeSave:protected] => Array

(

)

[_behaviors:protected] =>

)

)

[_previousValues:protected] => Array

(

)

[_options:protected] => Array

(

)

[_deleted:protected] =>

[_readOnly:protected] =>

[_writePending:protected] =>

[_writeRunning:protected] =>

[_errors:protected] => Array

(

)

[_whenSaveable:protected] => Array

(

)

[_cascadeSave:protected] => Array

(

)

[_behaviors:protected] =>

)

)

[_previousValues:protected] => Array

(

)

[_options:protected] => Array

(

)

[_deleted:protected] =>

[_readOnly:protected] =>

[_writePending:protected] =>

[_writeRunning:protected] =>

[_errors:protected] => Array

(

)

[_whenSaveable:protected] => Array

(

)

[_cascadeSave:protected] => Array

(

)

[_behaviors:protected] =>

)

[22963] => ThemeHouse\XPress\XF\Entity\Thread Object

(

[_uniqueEntityId:XF\Mvc\Entity\Entity:private] => 57

[rootClass:protected] => XF\Entity\Thread

[_useReplaceInto:protected] =>

[_newValues:protected] => Array

(

)

[_values:protected] => Array

(

[thread_id] => 22963

[node_id] => 367

[title] => Siemens’ PAVE360 to support Arm Zena Compute Subsystems

[reply_count] => 0

[view_count] => 588

[user_id] => 25277

[username] => AmandaK

[post_date] => 1749175592

[sticky] => 0

[discussion_state] => visible

[discussion_open] => 1

[discussion_type] => discussion

[first_post_id] => 87118

[first_post_reaction_score] => 0

[first_post_reactions] => []

[last_post_date] => 1749175592

[last_post_id] => 87118

[last_post_user_id] => 25277

[last_post_username] => AmandaK

[prefix_id] => 0

[tags] => []

[custom_fields] => []

[vote_score] => 0

[vote_count] => 0

[type_data] => []

)

[_relations:protected] => Array

(

[Forum] => XF\Entity\Forum Object

(

[_uniqueEntityId:XF\Mvc\Entity\Entity:private] => 70

[rootClass:protected] => XF\Entity\Forum

[_useReplaceInto:protected] =>

[_newValues:protected] => Array

(

)

[_values:protected] => Array

(

[node_id] => 367

[discussion_count] => 322

[message_count] => 324

[last_post_id] => 88097

[last_post_date] => 1751328409

[last_post_user_id] => 25277

[last_post_username] => AmandaK

[last_thread_id] => 23114

[last_thread_title] => BAC to build next-generation Mono road legal supercar with Siemens Xcelerator

[last_thread_prefix_id] => 0

[moderate_threads] => 1

[moderate_replies] => 1

[allow_posting] => 1

[count_messages] => 1

[find_new] => 1

[allow_index] => allow

[index_criteria] =>

[field_cache] => []

[prefix_cache] => []

[prompt_cache] => []

[default_prefix_id] => 0

[default_sort_order] => last_post_date

[default_sort_direction] => desc

[list_date_limit_days] => 0

[require_prefix] => 0

[allowed_watch_notifications] => all

[min_tags] => 0

[forum_type_id] => discussion

[type_config] => {"allowed_thread_types":["poll"],"allow_answer_voting":false,"allow_answer_downvote":false}

)

[_relations:protected] => Array

(

[Node] => XF\Entity\Node Object

(

[_uniqueEntityId:XF\Mvc\Entity\Entity:private] => 48

[rootClass:protected] => XF\Entity\Node

[_useReplaceInto:protected] =>

[_newValues:protected] => Array

(

)

[_values:protected] => Array

(

[node_id] => 367

[title] => Siemens EDA

[description] =>

[node_name] =>

[node_type_id] => Forum

[parent_node_id] => 355

[display_order] => 380

[display_in_list] => 1

[lft] => 97

[rgt] => 98

[depth] => 2

[style_id] => 0

[effective_style_id] => 4

[breadcrumb_data] => {"385":{"node_id":385,"title":"Companies","depth":0,"lft":13,"node_name":null,"node_type_id":"LinkForum","display_in_list":true},"355":{"node_id":355,"title":"Company Forums","depth":1,"lft":14,"node_name":null,"node_type_id":"Category","display_in_list":true}}

[navigation_id] =>

[effective_navigation_id] =>

)

[_relations:protected] => Array

(

)

[_previousValues:protected] => Array

(

)

[_options:protected] => Array

(

)

[_deleted:protected] =>

[_readOnly:protected] =>

[_writePending:protected] =>

[_writeRunning:protected] =>

[_errors:protected] => Array

(

)

[_whenSaveable:protected] => Array

(

)

[_cascadeSave:protected] => Array

(

)

[_behaviors:protected] =>

)

)

[_previousValues:protected] => Array

(

)

[_options:protected] => Array

(

)

[_deleted:protected] =>

[_readOnly:protected] =>

[_writePending:protected] =>

[_writeRunning:protected] =>

[_errors:protected] => Array

(

)

[_whenSaveable:protected] => Array

(

)

[_cascadeSave:protected] => Array

(

)

[_behaviors:protected] =>

)

)

[_previousValues:protected] => Array

(

)

[_options:protected] => Array

(

)

[_deleted:protected] =>

[_readOnly:protected] =>

[_writePending:protected] =>

[_writeRunning:protected] =>

[_errors:protected] => Array

(

)

[_whenSaveable:protected] => Array

(

)

[_cascadeSave:protected] => Array

(

)

[_behaviors:protected] =>

)

[22962] => ThemeHouse\XPress\XF\Entity\Thread Object

(

[_uniqueEntityId:XF\Mvc\Entity\Entity:private] => 58

[rootClass:protected] => XF\Entity\Thread

[_useReplaceInto:protected] =>

[_newValues:protected] => Array

(

)

[_values:protected] => Array

(

[thread_id] => 22962

[node_id] => 367

[title] => Techcellence Awards recognizes digital transformation, sustainability and innovation leaders from the Siemens community

[reply_count] => 0

[view_count] => 661

[user_id] => 25277

[username] => AmandaK

[post_date] => 1749175542

[sticky] => 0

[discussion_state] => visible

[discussion_open] => 1

[discussion_type] => discussion

[first_post_id] => 87117

[first_post_reaction_score] => 0

[first_post_reactions] => []

[last_post_date] => 1749175542

[last_post_id] => 87117

[last_post_user_id] => 25277

[last_post_username] => AmandaK

[prefix_id] => 0

[tags] => []

[custom_fields] => []

[vote_score] => 0

[vote_count] => 0

[type_data] => []

)

[_relations:protected] => Array

(

[Forum] => XF\Entity\Forum Object

(

[_uniqueEntityId:XF\Mvc\Entity\Entity:private] => 70

[rootClass:protected] => XF\Entity\Forum

[_useReplaceInto:protected] =>

[_newValues:protected] => Array

(

)

[_values:protected] => Array

(

[node_id] => 367

[discussion_count] => 322

[message_count] => 324

[last_post_id] => 88097

[last_post_date] => 1751328409

[last_post_user_id] => 25277

[last_post_username] => AmandaK

[last_thread_id] => 23114

[last_thread_title] => BAC to build next-generation Mono road legal supercar with Siemens Xcelerator

[last_thread_prefix_id] => 0

[moderate_threads] => 1

[moderate_replies] => 1

[allow_posting] => 1

[count_messages] => 1

[find_new] => 1

[allow_index] => allow

[index_criteria] =>

[field_cache] => []

[prefix_cache] => []

[prompt_cache] => []

[default_prefix_id] => 0

[default_sort_order] => last_post_date

[default_sort_direction] => desc

[list_date_limit_days] => 0

[require_prefix] => 0

[allowed_watch_notifications] => all

[min_tags] => 0

[forum_type_id] => discussion

[type_config] => {"allowed_thread_types":["poll"],"allow_answer_voting":false,"allow_answer_downvote":false}

)

[_relations:protected] => Array

(

[Node] => XF\Entity\Node Object

(

[_uniqueEntityId:XF\Mvc\Entity\Entity:private] => 48

[rootClass:protected] => XF\Entity\Node

[_useReplaceInto:protected] =>

[_newValues:protected] => Array

(

)

[_values:protected] => Array

(

[node_id] => 367

[title] => Siemens EDA

[description] =>

[node_name] =>

[node_type_id] => Forum

[parent_node_id] => 355

[display_order] => 380

[display_in_list] => 1

[lft] => 97

[rgt] => 98

[depth] => 2

[style_id] => 0

[effective_style_id] => 4

[breadcrumb_data] => {"385":{"node_id":385,"title":"Companies","depth":0,"lft":13,"node_name":null,"node_type_id":"LinkForum","display_in_list":true},"355":{"node_id":355,"title":"Company Forums","depth":1,"lft":14,"node_name":null,"node_type_id":"Category","display_in_list":true}}

[navigation_id] =>

[effective_navigation_id] =>

)

[_relations:protected] => Array

(

)

[_previousValues:protected] => Array

(

)

[_options:protected] => Array

(

)

[_deleted:protected] =>

[_readOnly:protected] =>

[_writePending:protected] =>

[_writeRunning:protected] =>

[_errors:protected] => Array

(

)

[_whenSaveable:protected] => Array

(

)

[_cascadeSave:protected] => Array

(

)

[_behaviors:protected] =>

)

)

[_previousValues:protected] => Array

(

)

[_options:protected] => Array

(

)

[_deleted:protected] =>

[_readOnly:protected] =>

[_writePending:protected] =>

[_writeRunning:protected] =>

[_errors:protected] => Array

(

)

[_whenSaveable:protected] => Array

(

)

[_cascadeSave:protected] => Array

(

)

[_behaviors:protected] =>

)

)

[_previousValues:protected] => Array

(

)

[_options:protected] => Array

(

)

[_deleted:protected] =>

[_readOnly:protected] =>

[_writePending:protected] =>

[_writeRunning:protected] =>

[_errors:protected] => Array

(

)

[_whenSaveable:protected] => Array

(

)

[_cascadeSave:protected] => Array

(

)

[_behaviors:protected] =>

)

[22961] => ThemeHouse\XPress\XF\Entity\Thread Object

(

[_uniqueEntityId:XF\Mvc\Entity\Entity:private] => 59

[rootClass:protected] => XF\Entity\Thread

[_useReplaceInto:protected] =>

[_newValues:protected] => Array

(

)

[_values:protected] => Array

(

[thread_id] => 22961

[node_id] => 367

[title] => Siemens wins IDC 2024 SaaS customer satisfaction award for PLM and CAD

[reply_count] => 0

[view_count] => 511

[user_id] => 25277

[username] => AmandaK

[post_date] => 1749175472

[sticky] => 0

[discussion_state] => visible

[discussion_open] => 1

[discussion_type] => discussion

[first_post_id] => 87116

[first_post_reaction_score] => 0

[first_post_reactions] => []

[last_post_date] => 1749175472

[last_post_id] => 87116

[last_post_user_id] => 25277

[last_post_username] => AmandaK

[prefix_id] => 0

[tags] => []

[custom_fields] => []

[vote_score] => 0

[vote_count] => 0

[type_data] => []

)

[_relations:protected] => Array

(

[Forum] => XF\Entity\Forum Object

(

[_uniqueEntityId:XF\Mvc\Entity\Entity:private] => 70

[rootClass:protected] => XF\Entity\Forum

[_useReplaceInto:protected] =>

[_newValues:protected] => Array

(

)

[_values:protected] => Array

(

[node_id] => 367

[discussion_count] => 322

[message_count] => 324

[last_post_id] => 88097

[last_post_date] => 1751328409

[last_post_user_id] => 25277

[last_post_username] => AmandaK

[last_thread_id] => 23114

[last_thread_title] => BAC to build next-generation Mono road legal supercar with Siemens Xcelerator

[last_thread_prefix_id] => 0

[moderate_threads] => 1

[moderate_replies] => 1

[allow_posting] => 1

[count_messages] => 1

[find_new] => 1

[allow_index] => allow

[index_criteria] =>

[field_cache] => []

[prefix_cache] => []

[prompt_cache] => []

[default_prefix_id] => 0

[default_sort_order] => last_post_date

[default_sort_direction] => desc

[list_date_limit_days] => 0

[require_prefix] => 0

[allowed_watch_notifications] => all

[min_tags] => 0

[forum_type_id] => discussion

[type_config] => {"allowed_thread_types":["poll"],"allow_answer_voting":false,"allow_answer_downvote":false}

)

[_relations:protected] => Array

(

[Node] => XF\Entity\Node Object

(

[_uniqueEntityId:XF\Mvc\Entity\Entity:private] => 48

[rootClass:protected] => XF\Entity\Node

[_useReplaceInto:protected] =>

[_newValues:protected] => Array

(

)

[_values:protected] => Array

(

[node_id] => 367

[title] => Siemens EDA

[description] =>

[node_name] =>

[node_type_id] => Forum

[parent_node_id] => 355

[display_order] => 380

[display_in_list] => 1

[lft] => 97

[rgt] => 98

[depth] => 2

[style_id] => 0

[effective_style_id] => 4

[breadcrumb_data] => {"385":{"node_id":385,"title":"Companies","depth":0,"lft":13,"node_name":null,"node_type_id":"LinkForum","display_in_list":true},"355":{"node_id":355,"title":"Company Forums","depth":1,"lft":14,"node_name":null,"node_type_id":"Category","display_in_list":true}}

[navigation_id] =>

[effective_navigation_id] =>

)

[_relations:protected] => Array

(

)

[_previousValues:protected] => Array

(

)

[_options:protected] => Array

(

)

[_deleted:protected] =>

[_readOnly:protected] =>

[_writePending:protected] =>

[_writeRunning:protected] =>

[_errors:protected] => Array

(

)

[_whenSaveable:protected] => Array

(

)

[_cascadeSave:protected] => Array

(

)

[_behaviors:protected] =>

)

)

[_previousValues:protected] => Array

(

)

[_options:protected] => Array

(

)

[_deleted:protected] =>

[_readOnly:protected] =>

[_writePending:protected] =>

[_writeRunning:protected] =>

[_errors:protected] => Array

(

)

[_whenSaveable:protected] => Array

(

)

[_cascadeSave:protected] => Array

(

)

[_behaviors:protected] =>

)

)

[_previousValues:protected] => Array

(

)

[_options:protected] => Array

(

)

[_deleted:protected] =>

[_readOnly:protected] =>

[_writePending:protected] =>

[_writeRunning:protected] =>

[_errors:protected] => Array

(

)

[_whenSaveable:protected] => Array

(

)

[_cascadeSave:protected] => Array

(

)

[_behaviors:protected] =>

)

[22960] => ThemeHouse\XPress\XF\Entity\Thread Object

(

[_uniqueEntityId:XF\Mvc\Entity\Entity:private] => 60

[rootClass:protected] => XF\Entity\Thread

[_useReplaceInto:protected] =>

[_newValues:protected] => Array

(

)

[_values:protected] => Array

(

[thread_id] => 22960

[node_id] => 367

[title] => Siemens and Northrop Grumman continue collaboration to advance digital ecosystem

[reply_count] => 0

[view_count] => 484

[user_id] => 25277

[username] => AmandaK

[post_date] => 1749175415

[sticky] => 0

[discussion_state] => visible

[discussion_open] => 1

[discussion_type] => discussion

[first_post_id] => 87115

[first_post_reaction_score] => 0

[first_post_reactions] => []

[last_post_date] => 1749175415

[last_post_id] => 87115

[last_post_user_id] => 25277

[last_post_username] => AmandaK

[prefix_id] => 0

[tags] => []

[custom_fields] => []

[vote_score] => 0

[vote_count] => 0

[type_data] => []

)

[_relations:protected] => Array

(

[Forum] => XF\Entity\Forum Object

(

[_uniqueEntityId:XF\Mvc\Entity\Entity:private] => 70

[rootClass:protected] => XF\Entity\Forum

[_useReplaceInto:protected] =>

[_newValues:protected] => Array

(

)

[_values:protected] => Array

(

[node_id] => 367

[discussion_count] => 322

[message_count] => 324

[last_post_id] => 88097

[last_post_date] => 1751328409

[last_post_user_id] => 25277

[last_post_username] => AmandaK

[last_thread_id] => 23114

[last_thread_title] => BAC to build next-generation Mono road legal supercar with Siemens Xcelerator

[last_thread_prefix_id] => 0

[moderate_threads] => 1

[moderate_replies] => 1

[allow_posting] => 1

[count_messages] => 1

[find_new] => 1

[allow_index] => allow

[index_criteria] =>

[field_cache] => []

[prefix_cache] => []

[prompt_cache] => []

[default_prefix_id] => 0

[default_sort_order] => last_post_date

[default_sort_direction] => desc

[list_date_limit_days] => 0

[require_prefix] => 0

[allowed_watch_notifications] => all

[min_tags] => 0

[forum_type_id] => discussion

[type_config] => {"allowed_thread_types":["poll"],"allow_answer_voting":false,"allow_answer_downvote":false}

)

[_relations:protected] => Array

(

[Node] => XF\Entity\Node Object

(

[_uniqueEntityId:XF\Mvc\Entity\Entity:private] => 48

[rootClass:protected] => XF\Entity\Node

[_useReplaceInto:protected] =>

[_newValues:protected] => Array

(

)

[_values:protected] => Array

(

[node_id] => 367

[title] => Siemens EDA

[description] =>

[node_name] =>

[node_type_id] => Forum

[parent_node_id] => 355

[display_order] => 380

[display_in_list] => 1

[lft] => 97

[rgt] => 98

[depth] => 2

[style_id] => 0

[effective_style_id] => 4

[breadcrumb_data] => {"385":{"node_id":385,"title":"Companies","depth":0,"lft":13,"node_name":null,"node_type_id":"LinkForum","display_in_list":true},"355":{"node_id":355,"title":"Company Forums","depth":1,"lft":14,"node_name":null,"node_type_id":"Category","display_in_list":true}}

[navigation_id] =>

[effective_navigation_id] =>

)

[_relations:protected] => Array

(

)

[_previousValues:protected] => Array

(

)

[_options:protected] => Array

(

)

[_deleted:protected] =>

[_readOnly:protected] =>

[_writePending:protected] =>

[_writeRunning:protected] =>

[_errors:protected] => Array

(

)

[_whenSaveable:protected] => Array

(

)

[_cascadeSave:protected] => Array

(

)

[_behaviors:protected] =>

)

)

[_previousValues:protected] => Array

(

)

[_options:protected] => Array

(

)

[_deleted:protected] =>

[_readOnly:protected] =>

[_writePending:protected] =>

[_writeRunning:protected] =>

[_errors:protected] => Array

(

)

[_whenSaveable:protected] => Array

(

)

[_cascadeSave:protected] => Array

(

)

[_behaviors:protected] =>

)

)

[_previousValues:protected] => Array

(

)

[_options:protected] => Array

(

)

[_deleted:protected] =>

[_readOnly:protected] =>

[_writePending:protected] =>

[_writeRunning:protected] =>

[_errors:protected] => Array

(

)

[_whenSaveable:protected] => Array

(

)

[_cascadeSave:protected] => Array

(

)

[_behaviors:protected] =>

)

[22942] => ThemeHouse\XPress\XF\Entity\Thread Object

(

[_uniqueEntityId:XF\Mvc\Entity\Entity:private] => 61

[rootClass:protected] => XF\Entity\Thread

[_useReplaceInto:protected] =>

[_newValues:protected] => Array

(

)

[_values:protected] => Array

(

[thread_id] => 22942

[node_id] => 367

[title] => Siemens bi-weekly webinar update

[reply_count] => 0

[view_count] => 581

[user_id] => 25277

[username] => AmandaK

[post_date] => 1748897759

[sticky] => 0

[discussion_state] => visible

[discussion_open] => 1

[discussion_type] => discussion

[first_post_id] => 86953

[first_post_reaction_score] => 0

[first_post_reactions] => []

[last_post_date] => 1748897759

[last_post_id] => 86953

[last_post_user_id] => 25277

[last_post_username] => AmandaK

[prefix_id] => 0

[tags] => []

[custom_fields] => []

[vote_score] => 0

[vote_count] => 0

[type_data] => []

)

[_relations:protected] => Array

(

[Forum] => XF\Entity\Forum Object

(

[_uniqueEntityId:XF\Mvc\Entity\Entity:private] => 70

[rootClass:protected] => XF\Entity\Forum

[_useReplaceInto:protected] =>

[_newValues:protected] => Array

(

)

[_values:protected] => Array

(

[node_id] => 367

[discussion_count] => 322

[message_count] => 324

[last_post_id] => 88097

[last_post_date] => 1751328409

[last_post_user_id] => 25277

[last_post_username] => AmandaK

[last_thread_id] => 23114

[last_thread_title] => BAC to build next-generation Mono road legal supercar with Siemens Xcelerator

[last_thread_prefix_id] => 0

[moderate_threads] => 1

[moderate_replies] => 1

[allow_posting] => 1

[count_messages] => 1

[find_new] => 1

[allow_index] => allow

[index_criteria] =>

[field_cache] => []

[prefix_cache] => []

[prompt_cache] => []

[default_prefix_id] => 0

[default_sort_order] => last_post_date

[default_sort_direction] => desc

[list_date_limit_days] => 0

[require_prefix] => 0

[allowed_watch_notifications] => all

[min_tags] => 0

[forum_type_id] => discussion

[type_config] => {"allowed_thread_types":["poll"],"allow_answer_voting":false,"allow_answer_downvote":false}

)

[_relations:protected] => Array

(

[Node] => XF\Entity\Node Object

(

[_uniqueEntityId:XF\Mvc\Entity\Entity:private] => 48

[rootClass:protected] => XF\Entity\Node

[_useReplaceInto:protected] =>

[_newValues:protected] => Array

(

)

[_values:protected] => Array

(

[node_id] => 367

[title] => Siemens EDA

[description] =>

[node_name] =>

[node_type_id] => Forum

[parent_node_id] => 355

[display_order] => 380

[display_in_list] => 1

[lft] => 97

[rgt] => 98

[depth] => 2

[style_id] => 0

[effective_style_id] => 4

[breadcrumb_data] => {"385":{"node_id":385,"title":"Companies","depth":0,"lft":13,"node_name":null,"node_type_id":"LinkForum","display_in_list":true},"355":{"node_id":355,"title":"Company Forums","depth":1,"lft":14,"node_name":null,"node_type_id":"Category","display_in_list":true}}

[navigation_id] =>

[effective_navigation_id] =>

)

[_relations:protected] => Array

(

)

[_previousValues:protected] => Array

(

)

[_options:protected] => Array

(

)

[_deleted:protected] =>

[_readOnly:protected] =>

[_writePending:protected] =>

[_writeRunning:protected] =>

[_errors:protected] => Array

(

)

[_whenSaveable:protected] => Array

(

)

[_cascadeSave:protected] => Array

(

)

[_behaviors:protected] =>

)

)

[_previousValues:protected] => Array

(

)

[_options:protected] => Array

(

)

[_deleted:protected] =>

[_readOnly:protected] =>

[_writePending:protected] =>

[_writeRunning:protected] =>

[_errors:protected] => Array

(

)

[_whenSaveable:protected] => Array

(

)

[_cascadeSave:protected] => Array

(

)

[_behaviors:protected] =>

)

)

[_previousValues:protected] => Array

(

)

[_options:protected] => Array

(

)

[_deleted:protected] =>

[_readOnly:protected] =>

[_writePending:protected] =>

[_writeRunning:protected] =>

[_errors:protected] => Array

(

)

[_whenSaveable:protected] => Array

(

)

[_cascadeSave:protected] => Array

(

)

[_behaviors:protected] =>

)

[22941] => ThemeHouse\XPress\XF\Entity\Thread Object

(

[_uniqueEntityId:XF\Mvc\Entity\Entity:private] => 62

[rootClass:protected] => XF\Entity\Thread

[_useReplaceInto:protected] =>

[_newValues:protected] => Array

(

)

[_values:protected] => Array

(

[thread_id] => 22941

[node_id] => 367

[title] => Siemens and IBM collaborate to bring SysML v2 model-based systems engineering to Siemens Xcelerator

[reply_count] => 0

[view_count] => 508

[user_id] => 25277

[username] => AmandaK

[post_date] => 1748896474

[sticky] => 0

[discussion_state] => visible

[discussion_open] => 1

[discussion_type] => discussion

[first_post_id] => 86952

[first_post_reaction_score] => 0

[first_post_reactions] => []

[last_post_date] => 1748896474

[last_post_id] => 86952

[last_post_user_id] => 25277

[last_post_username] => AmandaK

[prefix_id] => 0

[tags] => []

[custom_fields] => []

[vote_score] => 0

[vote_count] => 0

[type_data] => []

)

[_relations:protected] => Array

(

[Forum] => XF\Entity\Forum Object

(

[_uniqueEntityId:XF\Mvc\Entity\Entity:private] => 70

[rootClass:protected] => XF\Entity\Forum

[_useReplaceInto:protected] =>

[_newValues:protected] => Array

(

)

[_values:protected] => Array

(

[node_id] => 367

[discussion_count] => 322

[message_count] => 324

[last_post_id] => 88097

[last_post_date] => 1751328409

[last_post_user_id] => 25277

[last_post_username] => AmandaK

[last_thread_id] => 23114

[last_thread_title] => BAC to build next-generation Mono road legal supercar with Siemens Xcelerator

[last_thread_prefix_id] => 0

[moderate_threads] => 1

[moderate_replies] => 1

[allow_posting] => 1

[count_messages] => 1

[find_new] => 1

[allow_index] => allow

[index_criteria] =>

[field_cache] => []

[prefix_cache] => []

[prompt_cache] => []

[default_prefix_id] => 0

[default_sort_order] => last_post_date

[default_sort_direction] => desc

[list_date_limit_days] => 0

[require_prefix] => 0

[allowed_watch_notifications] => all

[min_tags] => 0

[forum_type_id] => discussion

[type_config] => {"allowed_thread_types":["poll"],"allow_answer_voting":false,"allow_answer_downvote":false}

)

[_relations:protected] => Array

(

[Node] => XF\Entity\Node Object

(

[_uniqueEntityId:XF\Mvc\Entity\Entity:private] => 48

[rootClass:protected] => XF\Entity\Node

[_useReplaceInto:protected] =>

[_newValues:protected] => Array

(

)

[_values:protected] => Array

(

[node_id] => 367

[title] => Siemens EDA

[description] =>

[node_name] =>

[node_type_id] => Forum

[parent_node_id] => 355

[display_order] => 380

[display_in_list] => 1

[lft] => 97

[rgt] => 98

[depth] => 2

[style_id] => 0

[effective_style_id] => 4

[breadcrumb_data] => {"385":{"node_id":385,"title":"Companies","depth":0,"lft":13,"node_name":null,"node_type_id":"LinkForum","display_in_list":true},"355":{"node_id":355,"title":"Company Forums","depth":1,"lft":14,"node_name":null,"node_type_id":"Category","display_in_list":true}}

[navigation_id] =>

[effective_navigation_id] =>

)

[_relations:protected] => Array

(

)

[_previousValues:protected] => Array

(

)

[_options:protected] => Array

(

)

[_deleted:protected] =>

[_readOnly:protected] =>

[_writePending:protected] =>

[_writeRunning:protected] =>

[_errors:protected] => Array

(

)

[_whenSaveable:protected] => Array

(

)

[_cascadeSave:protected] => Array

(

)

[_behaviors:protected] =>

)

)

[_previousValues:protected] => Array

(

)

[_options:protected] => Array

(

)

[_deleted:protected] =>

[_readOnly:protected] =>

[_writePending:protected] =>

[_writeRunning:protected] =>

[_errors:protected] => Array

(

)

[_whenSaveable:protected] => Array

(

)

[_cascadeSave:protected] => Array

(

)

[_behaviors:protected] =>

)

)

[_previousValues:protected] => Array

(

)

[_options:protected] => Array

(

)

[_deleted:protected] =>

[_readOnly:protected] =>

[_writePending:protected] =>

[_writeRunning:protected] =>

[_errors:protected] => Array

(

)

[_whenSaveable:protected] => Array

(

)

[_cascadeSave:protected] => Array

(

)

[_behaviors:protected] =>

)

[22940] => ThemeHouse\XPress\XF\Entity\Thread Object

(

[_uniqueEntityId:XF\Mvc\Entity\Entity:private] => 63

[rootClass:protected] => XF\Entity\Thread

[_useReplaceInto:protected] =>

[_newValues:protected] => Array

(

)

[_values:protected] => Array

(

[thread_id] => 22940

[node_id] => 367

[title] => Siemens empowers future workforce with new industry credential

[reply_count] => 0

[view_count] => 490

[user_id] => 25277

[username] => AmandaK

[post_date] => 1748896341

[sticky] => 0

[discussion_state] => visible

[discussion_open] => 1

[discussion_type] => discussion

[first_post_id] => 86951

[first_post_reaction_score] => 0

[first_post_reactions] => []

[last_post_date] => 1748896341

[last_post_id] => 86951

[last_post_user_id] => 25277

[last_post_username] => AmandaK

[prefix_id] => 0

[tags] => []

[custom_fields] => []

[vote_score] => 0

[vote_count] => 0

[type_data] => []

)

[_relations:protected] => Array

(

[Forum] => XF\Entity\Forum Object

(

[_uniqueEntityId:XF\Mvc\Entity\Entity:private] => 70

[rootClass:protected] => XF\Entity\Forum

[_useReplaceInto:protected] =>

[_newValues:protected] => Array

(

)

[_values:protected] => Array

(

[node_id] => 367

[discussion_count] => 322

[message_count] => 324

[last_post_id] => 88097

[last_post_date] => 1751328409

[last_post_user_id] => 25277

[last_post_username] => AmandaK

[last_thread_id] => 23114

[last_thread_title] => BAC to build next-generation Mono road legal supercar with Siemens Xcelerator

[last_thread_prefix_id] => 0

[moderate_threads] => 1

[moderate_replies] => 1

[allow_posting] => 1

[count_messages] => 1

[find_new] => 1

[allow_index] => allow

[index_criteria] =>

[field_cache] => []

[prefix_cache] => []

[prompt_cache] => []

[default_prefix_id] => 0

[default_sort_order] => last_post_date

[default_sort_direction] => desc

[list_date_limit_days] => 0

[require_prefix] => 0

[allowed_watch_notifications] => all

[min_tags] => 0

[forum_type_id] => discussion

[type_config] => {"allowed_thread_types":["poll"],"allow_answer_voting":false,"allow_answer_downvote":false}

)

[_relations:protected] => Array

(

[Node] => XF\Entity\Node Object

(

[_uniqueEntityId:XF\Mvc\Entity\Entity:private] => 48

[rootClass:protected] => XF\Entity\Node

[_useReplaceInto:protected] =>

[_newValues:protected] => Array

(

)

[_values:protected] => Array

(

[node_id] => 367

[title] => Siemens EDA

[description] =>

[node_name] =>

[node_type_id] => Forum

[parent_node_id] => 355

[display_order] => 380

[display_in_list] => 1

[lft] => 97

[rgt] => 98

[depth] => 2

[style_id] => 0

[effective_style_id] => 4

[breadcrumb_data] => {"385":{"node_id":385,"title":"Companies","depth":0,"lft":13,"node_name":null,"node_type_id":"LinkForum","display_in_list":true},"355":{"node_id":355,"title":"Company Forums","depth":1,"lft":14,"node_name":null,"node_type_id":"Category","display_in_list":true}}

[navigation_id] =>

[effective_navigation_id] =>

)

[_relations:protected] => Array

(

)

[_previousValues:protected] => Array