You are currently viewing SemiWiki as a guest which gives you limited access to the site. To view blog comments and experience other SemiWiki features you must be a registered member. Registration is fast, simple, and absolutely free so please,

join our community today!

A comprehensive update to the EUV stochastic image model

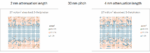

In extreme ultraviolet (EUV) lithography, photoelectron/secondary electron blur and secondary electron yield are known to drive stochastic fluctuations in the resist [1-3], leading to the formation of random defects and the degradation of pattern fidelity at advanced

…

Read More

In a DRAM chip, the memory array contains features which are the most densely packed, but at least they are regularly arranged. Outside the array, the regularity is lost, but in the most difficult cases, the pitches can still be comparable with those within the array, though generally larger. Such features include the lowest metal… Read More

Two approaches compared

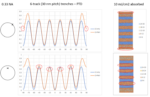

With half-pitch approaching 10 nm, EUV patterning is heavily impacted by stochastic effects, which are aggravated from reduced image contrast from electron blur [1]. A two-mask (“LELE”: Litho-Etch-Litho-Etch) approach was proposed to pattern core features for self-aligned double patterning (SADP)… Read More

Peak probability at zero distance actually makes no sense

In lithography, it is often stated that the best resolution that can be achieved depends on wavelength and numerical aperture (NA), but this actually only applies to the so-called “aerial” image. When the image is actually formed in the resist layer, it also depends on an… Read More

Previously, I had indicated how detrimental stochastic effects at pitches below 50 nm should lead to reconsidering the practical resolution limit for EUV lithography [1]. This is no exaggeration, as stochastic effects have been observed for 24 nm half-pitch several years ago [2,3]. This then leads to the question of whether … Read More

The majority of EUV production is on 5nm and 3nm node, implemented by late 2022. Metal oxide resists have not been brought into volume production yet [1,2], meaning that only organic chemically amplified resists (CARs) have been used instead until now. These resists have a typical absorption coefficient of 5/um [3,4], which means

…

Read More

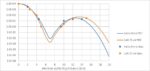

The discussion of any particular lithographic application often refers to imaging a single pitch, e.g., 30 nm pitch for a 5nm-family track metal scenario. However, it is always necessary to confirm the selected patterning techniques on the actual use case. The 7nm, 5nm, or 3nm 6-track cell has four minimum pitch tracks, flanked… Read More

On a DRAM chip, the patterning of features outside the cell array can be just as challenging as those within the array itself. While the array contains features which are the most densely packed, at least they are regularly arranged. On the other hand, outside the array, the regularity is lost, but the in the most difficult cases, … Read More

The release and scattering of photoelectrons and secondary electrons in EUV resists has often been glossed over in most studies in EUV lithography, despite being a fundamental factor in the image formation. Fortunately, Intel has provided us with a laboriously simulated electron release and scattering model, using the GEANT4… Read More

- This past weeks over-reaction to Canon echoes the Sculpta Scare

- Nanoimprint has made huge strides but is still not at all competitive

- Shows basic lack of understanding of technology by some pundits

- Chip industry has been searching for alternatives that don’t exist

Much ado about nothing much…..

This past week we … Read More