IC designers of passive devices often use empirical approaches to perform High Frequency Analysis (HFA), however there is at least one new approach being offered by Mentor Graphics using a tool flow of:

- Device detection and extraction with Calibre LVS and Calibre PERC

- Interconnect RLC extraction with Calibre xRC, Calibre xACT-3D and Calibre xL

- 3D-IC design rule checking with Calibre 3DSTACK

- Design environment integration with Calibre Interactive

A recent White Paper was written by Georgios Manetas, Ph.D, Developer and Christen Decoin, Program Manager. I’ll give you an overview from what I read.

Empirical Approach

You could first design multiple silicon test structures for HF devices, create a compact model with TCAD tools and then calibrate the models. Some reasons that make the empirical approach less appealing:

- Long development time for TCAD models

- Measurement-based design takes too much time

- Small changes to the passive device design require new models

- Parasitic and neighboring device interactions are not accounted for

- It’s difficult to perform design explorations

Mentor’s Approach

In the opening paragraph I listed all of the Mentor tools used to perform HFA of passives, and here are how the tools would be used:

- Inductor devices are automatically recognized in the IC layout with either Calibre nmLVS-H or Calibre xRC.

- Electro-Magnetic (EM) simulation with Calibre xACT-3D, producing S-parameters which are frequency dependent.

Accuracy versus Reference

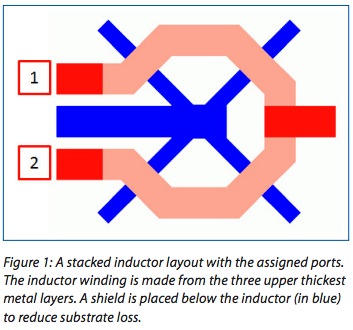

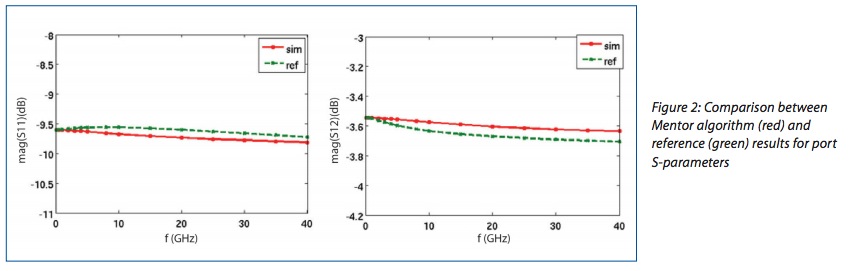

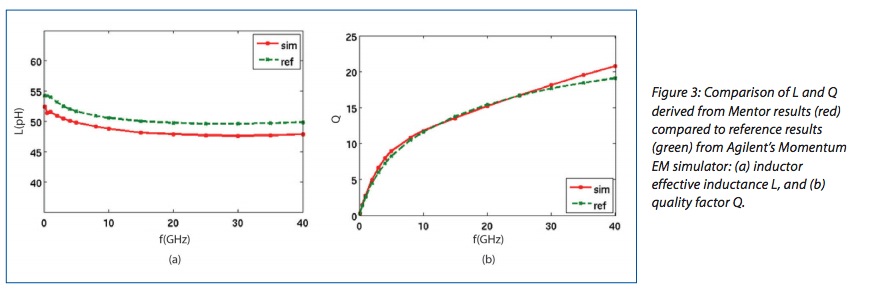

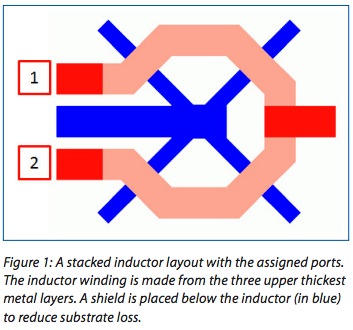

New approaches must be compared against a reference, so the inductor layout from Figure 1 was used and the two approaches compared. The Mentor S-parameters are within 5% of the reference (TCAD-based) L values, and within 10% of Q values:

Benefits of New Approach

So the accuracy of the new approach looks acceptable, other benefits include:

- Scalable tool flow, about 10X capacity and performance improvement over TCAD tools

- Enables device exploration, quickly

- Tools integrated with full-custom layout editors

- Analyze with black-boxing to exclude areas

- Extract and analyze in hours, not days

- Characterize both HF components and the IC interconnect

- At validation stage use highest accuracy with good turn around time

- For design exploration use good accuracy and fast turn around time

Summary

HF designers now have another choice besides a traditional TCAD approach by using Mentor tools. The complete white paper can be found here.

Further Reading

- Automating Complex Circuit Checking Tasks

- Measuring the Accuracy of a 3D Field Solver for IC Extraction

- Who Needs a 3D Field Solver for IC Design?

- An Affordable 3D Field Solver at DAC

- Memory Cell Characterization with a Fast 3D Field Solver

- A New Hierarchical 3D Field Solver

- Nimbic (formerly Physware) – 3D Field Solver in the Cloud or Desktop

- QuickCap for IC Extraction at DAC 2011

- 3D Transistors and IC Extraction Tools

- How Do You Extract 3D IC Structures?

- TSMC Theater Presentation: Lorentz Solution!

- Nimbic (formerly Physware) – 3D Field Solver in the Cloud or Desktop

- Why X-Fab uses 3D Resistance Extraction and Analysis

- Advanced Memory Cell Characterization with Calibre xACT 3D

- Reducing the Need for Guardbanding Flash ADC Designs

Comments

There are no comments yet.

You must register or log in to view/post comments.