Synopsys recently hosted an information rich-webinar, modestly titled “Improving Quality, FuSa, Reliability, and Security in Automotive Semiconductors”. I think they undersold the event; this was really about managing all of those things through the lifecycle of a car, in line with auto OEMs strategies for the future of the car. The standout message for me was total lifecycle management, from initial semiconductor architecture and design through end-of-lifecycle. I heartily recommend watching this webinar.

Heinz Wagensonner on an OEM perspective

Heinz is Manager of the Audi Progressive Semiconductor Program. He opened with a reminder of how an auto OEM sees the electronics future – advanced driving support, immersive experience and rethinking how to monetize added value options. One interesting set of stats is around mission profiles measured in hours of active operation over the car lifetime. For a traditional ICE car this has been 8000 hours (about 1.5 hours per day over a 15-year life). For an EV the mission profile extends to 55,000 hours, perhaps providing power to the house at night, and during the day charging or operating while supporting more functions than in earlier models. Heinz sees future EV profiles running to 130k hours, supporting multiple always-on functions such as face-id to enter and start the car, always on networks for OTA updates, and security to guard against threats.

Today advanced systems build on advanced processes (TSMC are already offering a 3nm early automotive development kit), very capable but with minimal track record in reliability (automakers used to require 5 years minimum). Domain specific devices with complex mission profiles compound the lack of track record. Mission profiles, advanced processes and advanced designs together point to a potential crisis for OEMs; an NHTSA report cites nearly 5 million ADAS-related recalls in 2022. At $1,000 per car, this is already a very expensive problem.

While mitigating the problem starts with strong design, Heinz also stresses in-service monitoring and compensation as an important part of the solution. On-chip sensors are central to these techniques. Such sensors play a role in preventive maintenance, perhaps warning the driver of an anticipated problem calling for a near term service visit. Or an imminent problem demanding the vehicle be switched to a safe state and the driver take immediate action (pull over to the side of the road).

Those features can prevent or mitigate a hazard in use before it happens. What happens when the car is taken in for a service? Heinz elaborated the highly complex and apparently quite brittle path to diagnose a root cause from initial service down through the value chain. As an example, 80% of ECUs assumed to be a problem root cause (and then replaced) prove on more detailed analysis not to have been the source of the problem! Yet following all diagnostic steps from initial service to a Tier 2 (semi supplier) can take 30 days if the root cause can be isolated. This overhead is unsustainable for managing warranty costs, potential for a recall, or worse.

He sees the path forward as a combination of on-chip sensor data, learning from prior problems through AI, combining in Signature Failure Analysis (SFA). Accumulating learned experience will lead to high confidence fixes which can be applied cost-effectively during a service call and can also provide effective and accurate feedback to Tier 1 and 2 suppliers. Some signatures may not map to a known problem and will still need to follow the long diagnostic path. However once resolved, they too can be added to the training database.

Alessandra Nardi on an EDA perspective

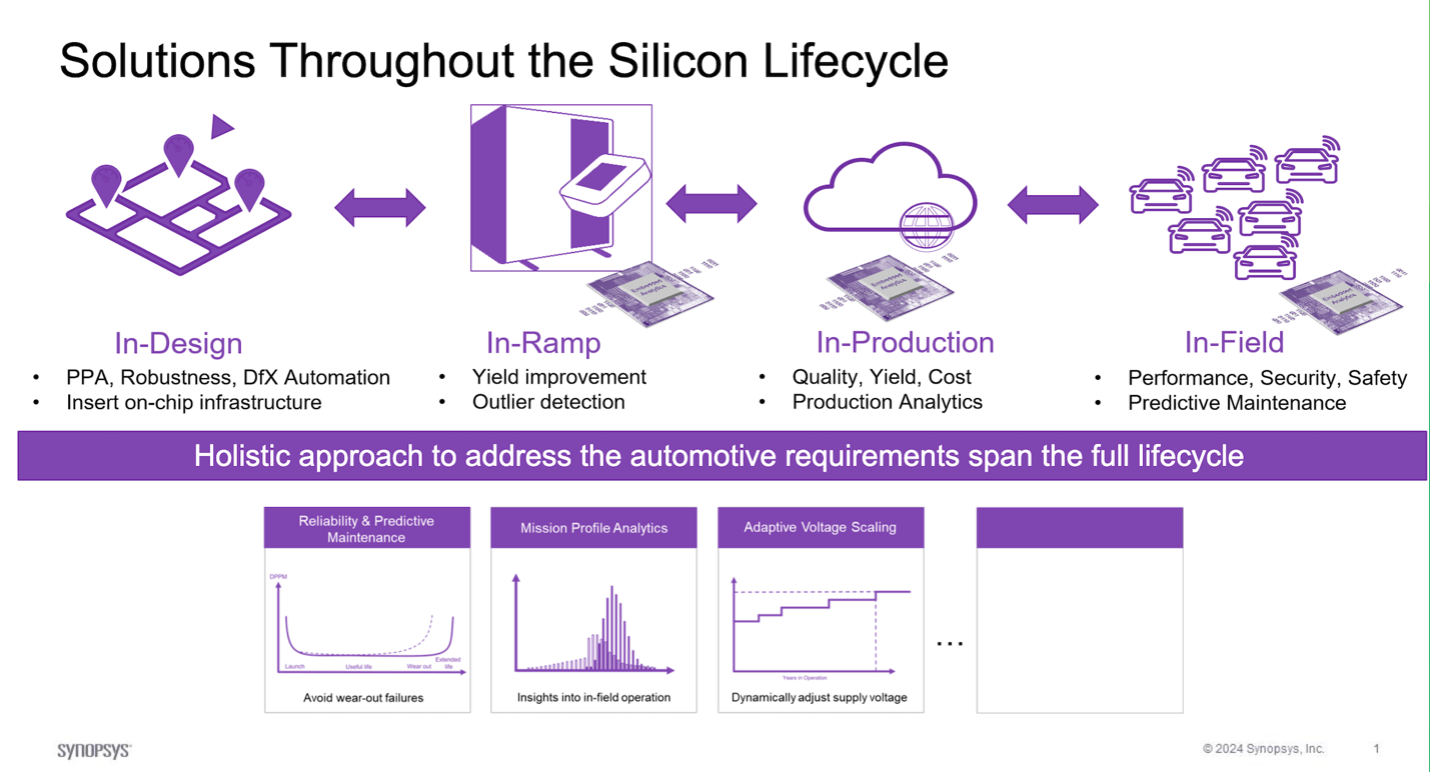

Alessandra is a Distinguished Architect in the Systems Solution group at Synopsys and a guru in automotive IMHO; every Alessandra talk I have attended has given me a better understanding of automotive system design and directions, with little to no product marketing. Her talk called for a holistic view of lifecycle challenges, starting with design then running through ramp, production, and in-field monitoring.

In-design optimizations for PPA and robustness are already well understood though still suggest opportunity for further advances. Here she highlighted need for improved modeling of uncertainty, through refined sensitivity analyses of variations based on different factors (voltage, temperature, etc) rather than blanket margins. Data gathered during ramp and production analyses through in-chip monitors placed during design will drive this learning. In turn that can drive yield and reliability optimizations and improvements to PPA, safety and other metrics. The same monitors can capture data during in-field analysis, feeding back information to the supply chain to drive additional optimizations while also enabling real-time tuning through techniques like adaptive voltage scaling.

The central component of in-chip monitor methods is a machine-learning system, gathering mission feedback from monitors to learn sensitivities/signatures for trends or outlier behaviors. In ramp or production these may suggest need for silicon or process revision fine-tuning. Similarly, an ML model can support in-field diagnoses and tuning.

Alessandra hinted that such lifetime optimization systems are not only important for automotive markets. Everything she and Heinz talked about is likely also important in aerospace and defense, industrial, medical and infrastructure markets though with different thresholds across the various metrics discussed in this webinar. I would imagine that even sustainability may play an increasing role, at least in product lifetimes and power consumption.

Fascinating discussion. Again, you can access the webinar HERE.

Also Read:

Early SoC Dynamic Power Analysis Needs Hardware Emulation

Synopsys Design IP for Modern SoCs and Multi-Die Systems

Synopsys Presents AI-Fueled Innovation at SNUG 2024

Share this post via:

Comments

There are no comments yet.

You must register or log in to view/post comments.