State-of-the-art electronics demand high performance, low power consumption, small footprint and high reliability from their semiconductor products. While this imperative is true across many different market segments, it is critical for applications such as the automotive/autonomous driving and data centers. As electronic devices become more intricate and compact, the margin of error increases, necessitating innovative approaches to ensure optimal performance and longevity.

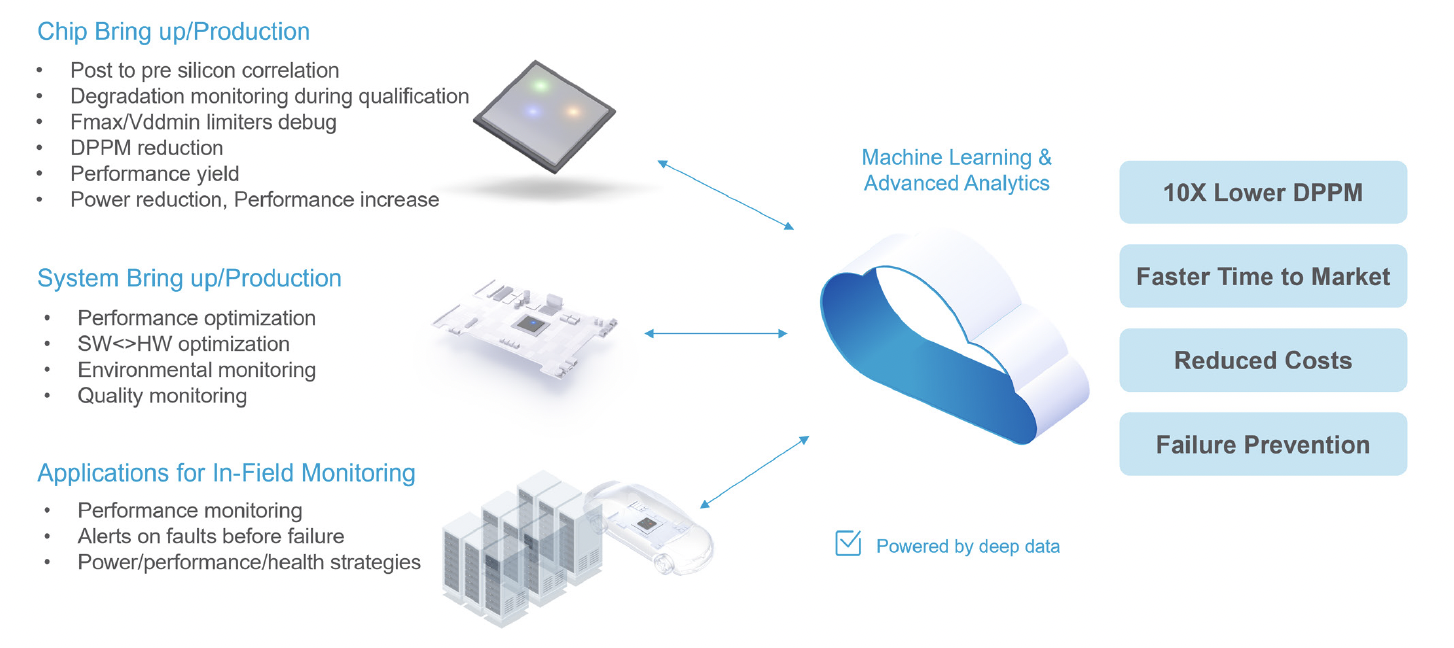

While traditional methods struggle to help deliver on this imperative, proteanTecs offers a comprehensive framework for enhancing product performance and reliability, through the integration deep data analytics. By combining data from specialty chip telemetry agents (monitoring IP) with machine learning (ML) algorithms, their solutions are deployed via cloud and embedded software to provide insights and visibility throughout the system lifecycle. These agents provide parametric design profiling, margin monitoring, power and reliability management, I/O channel health monitoring and in-field predictive monitoring. This groundbreaking solution is the proteanTecs On-Chip Monitoring and Deep Data Analytics System, and the company recently published a whitepaper on this subject matter. This whitepaper is an excellent read for everyone involved in the development of modern day applications that demand high performance and reliability. Following are some excerpts from that whitepaper.

On-Chip Monitoring and Analytics Platform

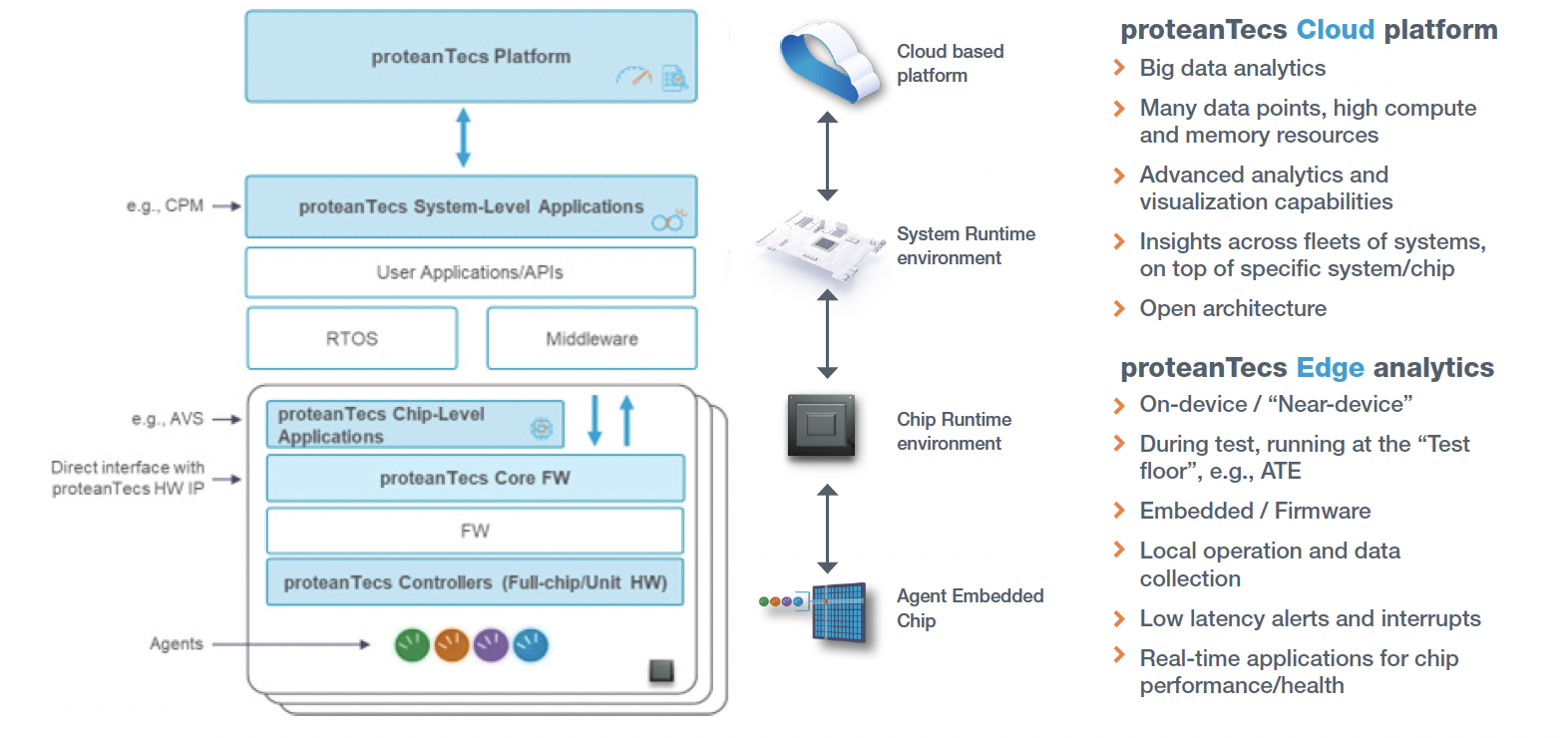

The success of the proteanTecs platform relies on two fundamental pillars, namely, comprehensive monitoring and data-driven analytics. By integrating these two elements into the chip design process, the company offers a holistic approach to optimization that covers the entire product lifecycle.

Ease of Implementing On-Chip Monitoring

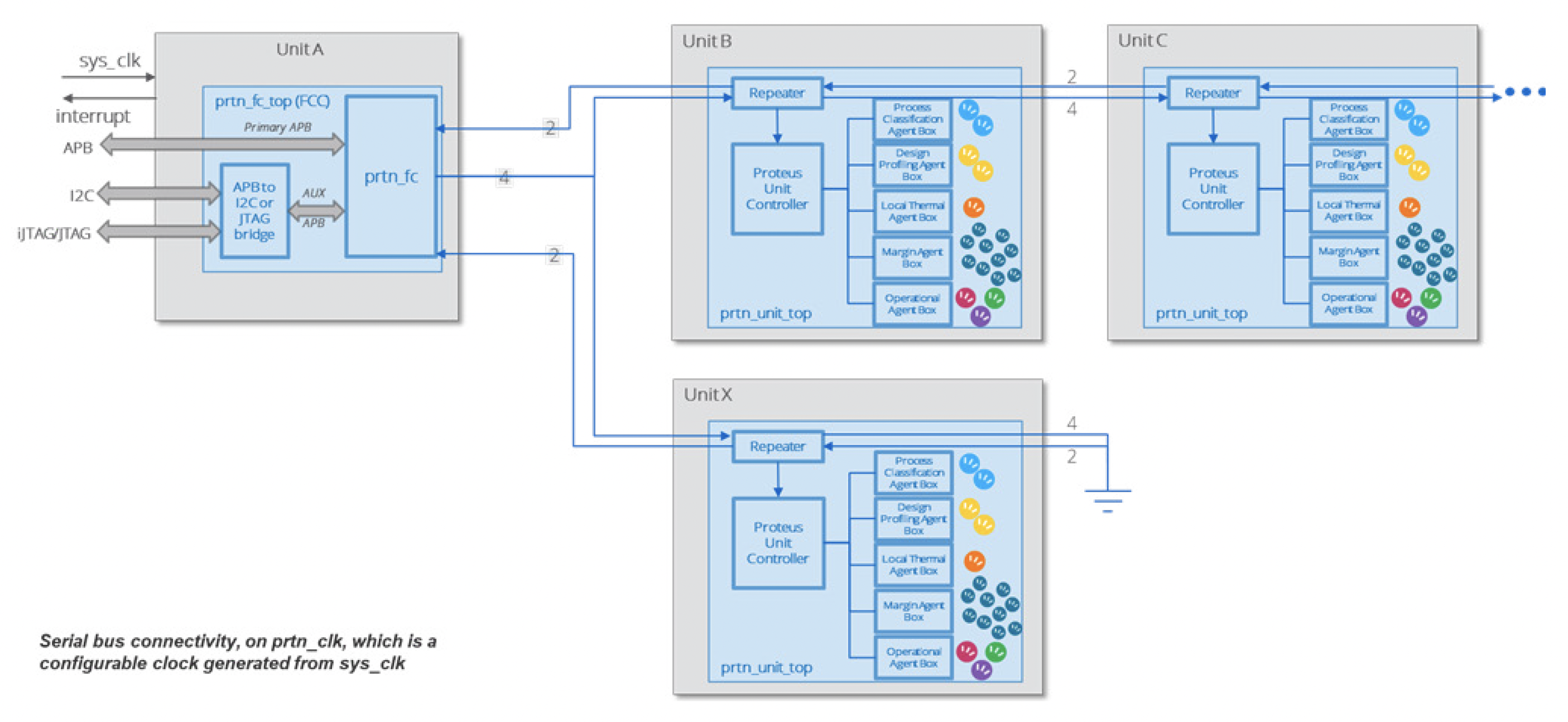

The key is the platform’s ability to meticulously monitor critical chip parameters in real-time. This is achieved through a network of proprietary monitors, called agents, that are strategically placed within the chip architecture. These agents continuously gather data on parameters such as voltage, temperature, timing margins, and interconnect quality, all while the chip is in operation. This dynamic monitoring unveils a wealth of insights, unearthing vital information about a chip’s behavior under various workloads, conditions, and over its operational lifetime.

The hardware IP system from proteanTecs includes an extensive array of monitors for gathering data and a Full Chip Controller (FCC) that serves as the central hub. The FCC interfaces to the various monitors and relays the gathered data to the firmware (FW), edge software (SW) and the cloud platform via standard interfaces like JTAG, APB and I2C.

Ease of Incorporating Data-Driven Analytics

The data collected by the on-chip agents become the foundation for the second pillar of the proteanTecs platform which is deep data analytics. The platform boasts a sophisticated cloud-based analytics infrastructure that ingests, processes, and interprets the data. This complex ecosystem deploys advanced algorithms and machine learning techniques to dissect the intricate relationships between the monitored parameters and the chip’s performance, reliability, and power consumption.

The proteanTecs Software (SW) analytics platform operates in the cloud, acting as an interface to gather data from various sources like wafer probe, Automated Test Equipment (ATE) vendors, and the system during both productization and normal operation. The platform excels in Agent fusion and leverages Agent measurements to offer a comprehensive understanding of both the chip and the system.

Benefits from the proteanTecs Solution

During the New Product Introduction (NPI) phase, the platform’s Process Classification Agent (PCA) and Design Profiling Agent (DPA) collaborate to provide a comprehensive view of process characteristics and design sensitivity. This helps with process tuning, optimal voltage-frequency binning, and power management strategies.

As chips move from development to mass production, proteanTecs’ Timing Margin Agents (MA) come into play. These agents enable the accurate measurement of timing margins during functional operation, offering insights into actual system behavior that generic ring oscillators or critical path replicas cannot replicate. This leads to better understanding and control of the system’s performance, power consumption, and reliability.

Workload Agents (WLA) enable visibility into the application workloads and their impact on the hardware. They serve as a proxy for how much voltage and temperature stress the chip has been exposed to, during normal operation. This is important to determine the remaining useful life of a product and for efficient power and performance management.

The voltage droop sensor (VDS) and local voltage and thermal sensors (LVTS) enable real-time power and temperature management during the operational phase of a chip’s life. This not only maximizes performance but also extends the chip’s longevity by preventing excessive thermal degradation.

The solution’s impact extends into in-field monitoring and lifetime assessment, with embedded on-board software, in-chip monitoring and cloud analytics. By continuously monitoring key parameters, including those susceptible to performance degradation and latent defects, proteanTecs enables early detection of abnormal behavior that may lead to eventual failures. This preemptive capability is invaluable in critical applications, such as data centers and automotive systems, where reliability is paramount.

Summary

By integrating proteanTecs on-chip monitoring and deep data analytics solutions into their products, manufacturers can enhance their systems’ longevity, resilience, safety, and performance. The system offers unparalleled insights into chip behavior, performance optimization, and reliability enhancement. The end-to-end health monitoring fosters optimal reliability, performance, power efficiency, and cost-effectiveness across a broad spectrum of applications, ranging from automotive to data centers and beyond.

You can download the entire whitepaper from here. To learn more about proteanTecs technology and solutions, visit www.proteanTecs.com.

Also Read:

Predictive Maintenance in the Context of Automotive Functional Safety

Maintaining Vehicles of the Future Using Deep Data Analytics

Share this post via:

Comments

There are no comments yet.

You must register or log in to view/post comments.