In my last corporate EDA job I had customers in Korea that were evaluating a new circuit simulator and getting strange results. When I asked, “Could you send me your test case?” the reply was always, “No, we cannot let any of our IC design data leave the building because of security concerns.”… Read More

Tag: calibre

December 1st – Hands-on Workshop with Calibre: DRC, LVS, DFM, xRC, ERC (Fremont, California)

I’ve blogged about the Calibre family of IC design tools before:

Smart Fill replaced Dummy Fill Approach in a DFM Flow

DRC Wiki

Graphical DRC vs Text-based DRC

Getting Real time Calibre DRC Results with Custom IC Editing

Transistor-level Electrical Rule Checking

Who Needs a 3D Field Solver for IC Design?

Prevention is Better… Read More

Parasitic Extraction—My Head Hurts!

By Carey Robertson, Director of Product Marketing, Mentor Graphics

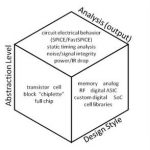

IC physical verification requires a number of different types of checking, the most familiar being design rule checking (DRC), layout vs. schematic (LVS) checking, and parasitic extraction combined with circuit simulation. Fundamentally, it does not matter… Read More

Oct 27 – Hands-on Workshop with Calibre: DRC, LVS, DFM, xRC, ERC (Fremont, California)

I’ve blogged about the Calibre family of IC design tools before:

Smart Fill replaced Dummy Fill Approach in a DFM Flow

Graphical DRC vs Text-based DRC

Getting Real time Calibre DRC Results with Custom IC Editing

Transistor-level Electrical Rule Checking

How ST-Ericsson Improved DFM Closure using SmartFill

DFM closure is a growing issue these days even at the 45nm node, and IC designers at ST-Ericsson have learned that transitioning from dummy fill to SmartFill has saved them time and improved their DFM score.

The SOC

ST-Ericsson designed an SOC for mobile platforms called the U8500 and their foundry choice was a 45nm node at STMicroelectronics… Read More

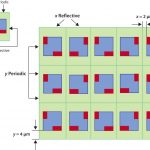

Memory Cell Characterization with a Fast 3D Field Solver

Memory designers need to predict the timing, current and power of their designs with high accuracy before tape-out to ensure that all the design goals will be met. Extracting the parasitic values from the IC layout and then running circuit simulation is a trusted methodology however the accuracy of the results ultimately depend… Read More

Aug 25th in Fremont, CA – Hands on Calibre workshop: DRC, LVS, xRC, ERC, DFM

I’ve blogged about the Calibre family of IC design tools before:

Smart Fill replaced Dummy Fill Approach in a DFM Flow

DRC Wiki

Graphical DRC vs Text-based DRC

Getting Real time Calibre DRC Results with Custom IC Editing

Transistor-level Electrical Rule Checking

Who Needs a 3D Field Solver for IC Design?

Prevention is Better… Read More

August 11th – Hands-on Workshop with Calibre: DRC, LVS, DFM, xRC, ERC

I’ve blogged about the Calibre family of IC design tools before:

Smart Fill replaced Dummy Fill Approach in a DFM Flow

DRC Wiki

Graphical DRC vs Text-based DRC

Getting Real time Calibre DRC Results with Custom IC Editing

Transistor-level Electrical Rule Checking

Who Needs a 3D Field Solver for IC Design?

Prevention is Better… Read More

Smart Fill Replaces Dummy Fill Approach in a DFM Flow

I met with Jeff Wilson, Product Marketing Manager at Mentor in the Calibre product group to learn more about Smart Fill versus Dummy Fill for DFM flows. Jeff works in the Wilsonville, Oregon office and we first meet at Silicon Compilers back in the 1990’s.

Dummy Fill

This diagram shows an IC layout layer on the left as originally… Read More

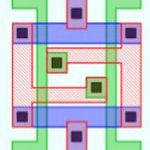

Graphical DRC vs Text-based DRC

Introduction

IC designs go through a layout process and then a verification of that layout to determine if the layout layer width and spacing rules conform to a set of manufacturing design rules. Adhering to the layout rules will ensure that your chip has acceptable yields.

At the 28nm node a typical DRC (Design Rule Check) deck will… Read More