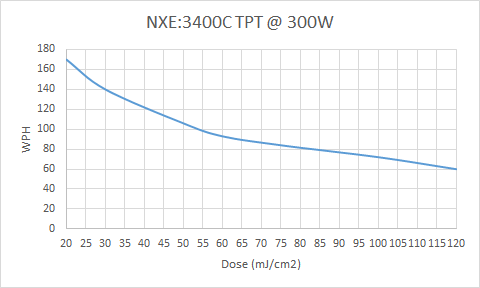

Recently, a patent application from TSMC [1] revealed target EUV doses used in the range of 30-45 mJ/cm2. However, it was also acknowledged in the same application that such doses were too low to prevent defects and roughness. Recent studies [2,3] have shown that by considering photon density along with blur, the associated shot noise could easily account for such defects and roughness. Given that the blur is on the order of 5 nm, we can easily estimate the suitable photon density, by taking 3 standard deviations as 10% of the nominal dose. This gives 3*sqrt(N)/N = 10%, or N = 900 photons, which are distributed, on average, over a 5 nm x 5 nm estimated blur area, giving 36 photons/nm2, or 53 mJ/cm2. Such a dose may be considered too high for satisfactory throughput, based on the throughput-dose curve below [4]:

Figure 1. Throughtput vs. dose for NXE:3400C EUV tool with 300W source [4].

Going from the usually specified 30 mJ/cm2 dose to 53 mJ/cm2 reduces the throughput from 140 to 100 WPH. If we consider not incident EUV dose, but actually absorbed EUV dose, to reach the 53 mJ/cm2 target, it gets even worse. A metal-organic resist (MOR) could absorb 55% of the dose, which would bring the required incident dose to 96 mJ/cm2, which means a throughput of around 75 WPH. A conventional chemically amplified resist (CAR) on the other hand, absorbs around 20% of the dose, leading to a required 265 mJ/cm2, which means around 30 WPH.

Not surprisingly, EUV users would want to find a way to stay below 50 mJ/cm2. The proposed approach described in US20210096473 [1] uses directional etching. The etch tool is modified to produce directed etching ion beams along one axis, so that etching only proceeds significantly along that axis and negligibly along the other axis. Note that normally, etching would be negligible along both axes. Presumably, such vertical etching would preserve pre-existing roughness. The obvious drawbacks of this directional etching approach are: (1) it’s limited to unidirectional features, and (2) line ends are hard to control.

A more accurate picture of EUV doses would require consideration of photoelectrons and secondary electrons, which would require intense calculations beyond the simple estimates here.

References

[1] R-G. Liu et al., US20210096473, assigned to TSMC.

[2] https://www.linkedin.com/pulse/stochastic-behavior-optical-images-impact-resolution-frederick-chen

[3] https://www.linkedin.com/pulse/blur-wavelength-determines-resolution-advanced-nodes-frederick-chen

[4] J. van Schoot et al., Proc. SPIE 11517, 1151712 (2021).

Share this post via:

Memory Matters: Signals from the 2025 NVM Survey