The goal of SoC design teams is to tape-out their project and receive working silicon on the first try, without discovering any bugs in silicon. To achieve this lofty goal requires all types of specialized checking and verification during the design phase to prevent bugs. There are checks at the system level, RTL level, gate level, transistor level and physical layout levels. One newer EDA company is Aniah, and their focus is on checking the correctness of IC designs at the transistor level through Electrical Rule Checking (ERC) by employing formal methods and smart clustering of errors

During ERC a formal tool can mistakenly report “false positives”, and these are false errors that shouldn’t have been reported. Real design errors that are not detected are called “false negatives”, so the ideal formal tool has zero false negatives. The Aniah formal ERC tool is called OneCheck, and I’ve just read their White Paper to get up to speed on how it works.

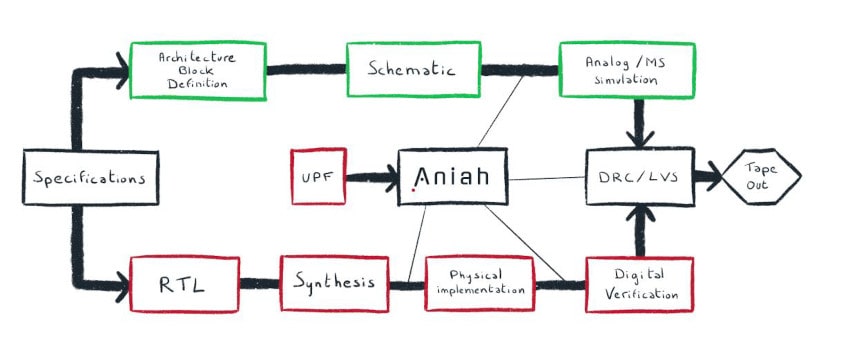

The Aniah OneCheck ERC can be run on a design in several places for IC flows to verify both analog and digital circuitry:

Some common design flaws caught by formal checkers include:

- Missing Level Shifters

- Floating Gates

- High Impedance states

- Floating Bulk

- Diode Leakage

- Electrical Overstress

False Errors

There are four typical classes of false errors that an ERC tool can be fooled by, so the following examples illustrate the challenges.

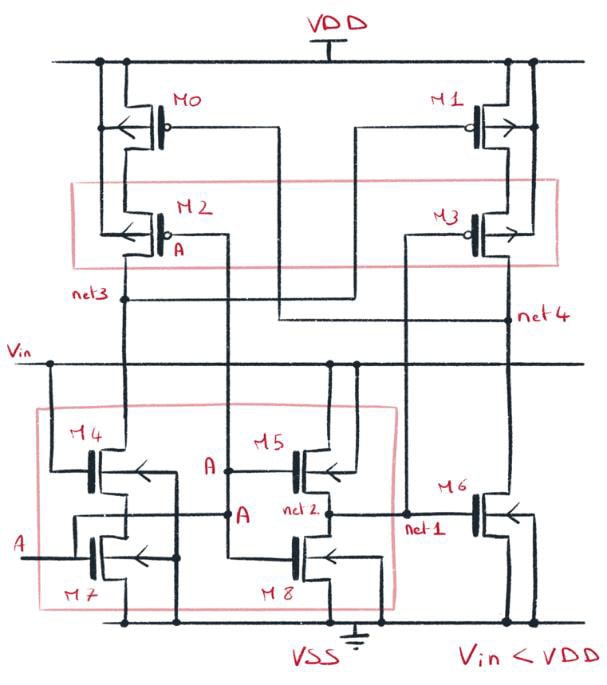

1. Topology Specific

The following circuit has two power domains – VDD, Vin; a level shifter is expected between them, and here the false error flags transistors M2 and M3, because their gates are connected to net A and Net 1 which are powered by Vin, not VDD. Transistors M0 and M1 actually control the “1” level.

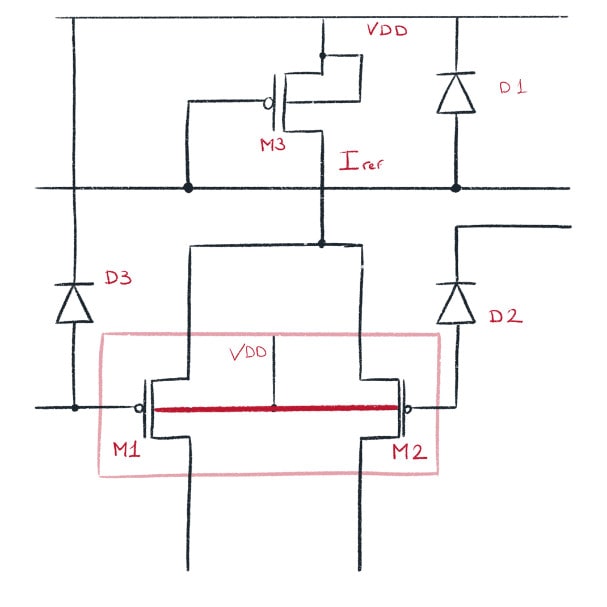

2. Analog Path

A differential amplifier has devices M1 and M2 that are biased to act as an amplifier with current provided by M3, yet a false error reports an analog path issue.

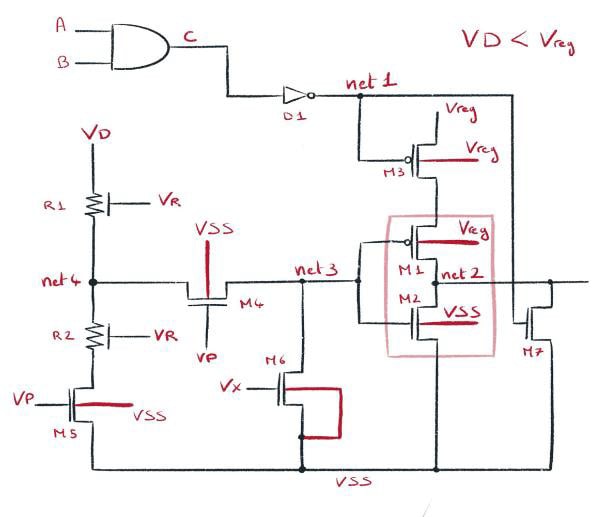

3. Impossible Path Logically

An inverter of M1, M2 is driven by a lower range signal. When net 3 is ‘1’, then M2 pulls down output net 2 to a ‘0’, but the false error reports a logic path through M3 and M1.

4. Missing supply in setup

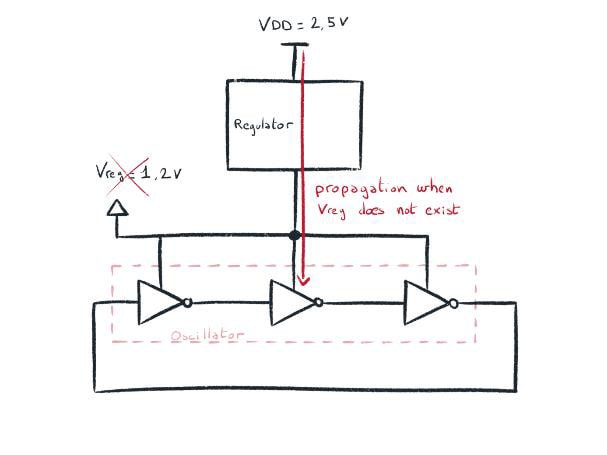

When a ring oscillator circuit requires a regulated supply value of 1.2V, but the regulator has a supply value of 2.5V, then a false error can be reported for electrical overstress.

False Error – Missing supply in setup

False Error – Missing supply in setup

OneCheck

The good news is that OneCheck from Aniah has a smart Clustering Root-Cause analysis methodology to handle these four types of false errors. This formal circuit checker doesn’t use any vectors because all circuit states are verified in just one run, which includes verification of all power states of each circuit. Commercial circuits on mature or latest generation nodes have been run through OneCheck, so it’s a reliable tool.

Your circuit design team can start using OneCheck after the first schematic netlists are entered, even before any simulations have been run. The actual run times of OneCheck are quite fast, typically just a few seconds on a mixed-signal designs with over 10 million transistors and more than 10,000 different power scenarios.

1. Topology Specific

OneCheck detects topology-related false errors like missing level shifters by performing pseudo-electrical analysis to model voltages and currents.

2. Analog Path

With Aniah OneCheck a user can identify and filter false errors with any current or voltage reference net.

3. Impossible path logically

The OneCheck tool finds all tree-like paths used by analog multiplexors, and the user can reject thousands of false errors quickly.

4. Missing supply in setup

All errors corresponding to a missing supply are clustered together, so users can easily update the power supply setup.

Summary

Finding circuit bugs before manufacturing is the preferred method to ensure first silicon success, so ERC is another tool for chip design teams to use. Other ERC tools report way too many false errors, so that his limited their acceptance in the design community. Aniah has delivered new formal technology to combat this issue of false errors for ERC.

Why not give OneCheck a try on some of your biggest IC designs, as the evaluation process is free and easy.

Read the full 11-page White Paper from Aniah online.

Related Blogs

- CEO Interview: Vincent Bligny of Aniah

- Aniah and Prophesee Announce collaboration

- Aniah validates both ISO9001 and ISO27001 certifications

Share this post via:

Comments

There are no comments yet.

You must register or log in to view/post comments.