In the pages of SemiWiki, we are usually talking about what to do with billions of really small transistors – for a change of pace today, we’ll discuss what to do with a few really big ones. Mentor Graphics has just announced their latest MicReD platform for thermal testing of IGBTs, experiencing a resurgence (pun intended) thanks to electric vehicles.

For those not familiar with high power transistors and automotive electronics, it might seem odd that Mentor sells a product to the car manufacturers and primary subsystem vendors to test IGBTs. Don’t the IGBT vendors characterize their products? That’s a complicated question, one Mentor has PhDs like Dr. John Parry, Electronics Industry Manager at the Mechanical Analysis Division, working on.

Of course the IGBT vendors characterize their product – the transistor die itself. Once that die is pulled out and put in automotive vendor-specific packaging with cooling measures, it becomes a system test problem. In some respects, it also resembles a HALT challenge, trying to predict how an IGBT module will hold up in the field over 10 years or more of use.

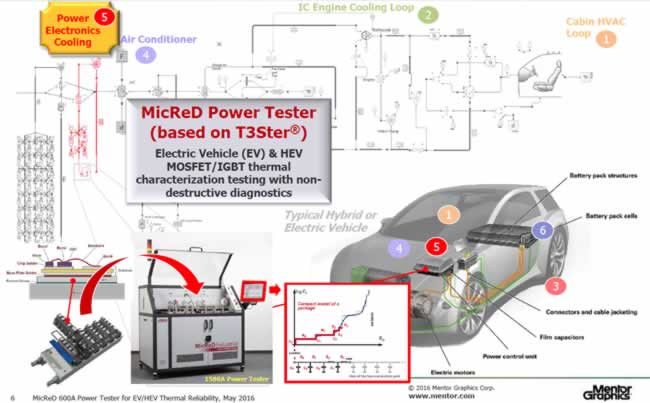

An IGBT module power tester has several roles at the automakers. Incoming device screening is only part of the capability. MicReD is intended more as a test platform to characterize and assess package development and reliability. As Dr. Parry pointed out in a recent interview, electric vehicles are now high in power electronics content. Optimizing the cooling for an IGBT module reduces weight, multiplied across dozens of modules in an EV, meaning lower cost and greater range.

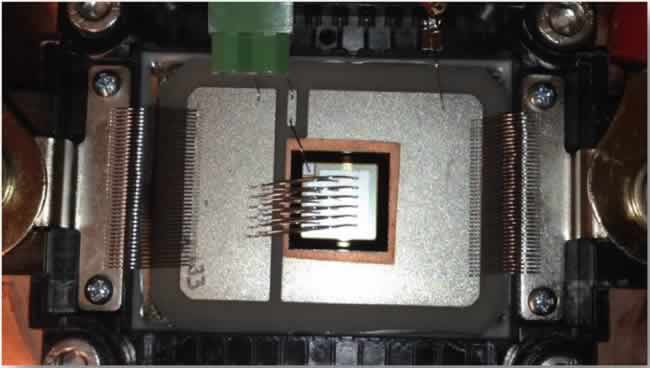

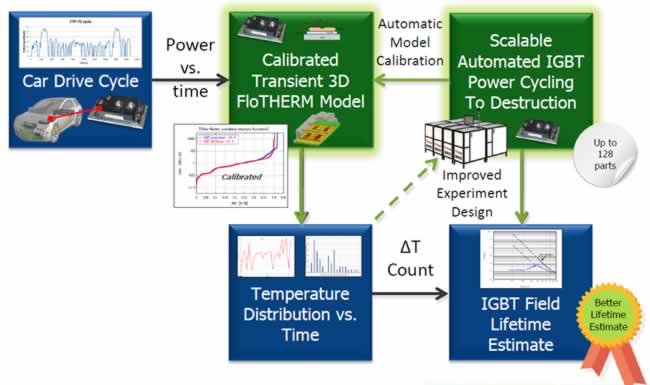

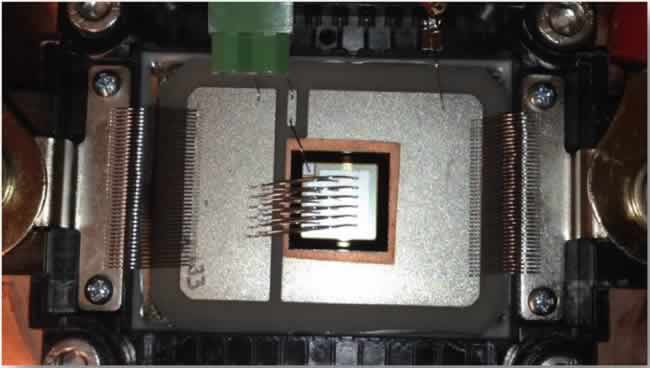

There are lots of ways to blow up an IGBT using just load cycling. Thermal effects can degrade the part itself between metallization layers, crack the die or substrate, erode wire bonds, or fatigue solder joints. By running various automated profiles of an EV drive cycle and measuring the temperature-time response, a “structure function” from the T3Ster software shows failure in progress for each IGBT under test without pushing the limits to destructive tests.

One problem is the test profiles and structure function are only as good as the 3D simulation model of temperature. Mentor’s Zoltan Sarkany, Product Specialist in the Mechanical Analysis Division, said a typical IGBT bandgap model can be off by 20% in how heat distributes over the stack, leaving an unpredictable hot spot. Mentor FloTHERM 11.1 develops a more accurate 3D CFD (computational fluid dynamics) picture of the bandgap, allowing a more accurate calibration of T3Ster leaving only a 0.5% error.

The new MicReD 600A Power Tester handles up to 16 IGBTs at a time, delivering 48V and 600A under load as the name implies. Eight power testers can be ganged for a capacity of 128 units concurrently – the AEC Q101 standard calls for 77 parts per test lot. Tests are controlled via an operator touch screen, and external cooling solutions are supported so more types of IGBT modules are testable.

It’s fascinating that so much attention is going into power electronics packaging R&D. However, speaking from a completely miserable experience of an early Saturn Vue Hybrid and its nightmare of electrical problems, better lifecycle prediction through testing is the only way to figure out what these new IGBT modules and subsystems will do over years of service in an EV.

More on the Mentor Graphics website:

MicReD Power Tester 600A product page

Share this post via:

Comments

0 Replies to “Testing IGBTs before they go into EVs”

You must register or log in to view/post comments.