This is the second in the series of “20 Questions with Wally Rhines”

At 8am on my first day of graduate school at Stanford, I joined the “Structure of Materials” class taught by Craig Barrett, the youngest faculty member in the Materials Science and Engineering Department. Craig had just returned from a post-doc in England and was energetically publishing papers, writing a book (along with Bill Nix and Alan Tetelman) and teaching classes. He passed out mimeographed copies (for a price) of the rough drafts of the book for the class text book. His distinguished undergraduate career in the same department led to a faculty appointment and his history at Stanford included a record in the high hurdles which still stood. Ultimately, his impatience with the academic world led to his departure to join Intel where he eventually became CEO (but that’s another story). Craig, as the youngest professor, also offered the benefit that he willingly joined the grad students at the “O” (short for Oasis) and purchased pitchers of beer when the graduate student money ran out (which was early in the evening).

There were lots of interesting people in engineering at Stanford at that time, since Frederick Terman, former Dean of Engineering had recruited a variety of rising stars in the semiconductor industry including William Shockley and Gerald Pearson, both of Bell Labs transistor fame. Shockley was more famous because of the Nobel Prize and, ultimately, more INFAMOUS as he redirected his research from semiconductors to racial differences in intelligence. Since he had the office next to ours, we kept a sign in the window labeled “Shockley’s Office is Next Door” just in case someone with a fire bomb lost direction or became confused. The McCullough Building was hardly a safe place anyway with research in II-VI and III-V semiconductors down the hall involving elemental materials that were poisonous in the parts per billion range. And T.J. Rodgers, who would in the future found Cypress Semiconductor, was running experiments in the basement with the first of Stanford’s ion implanters, causing unexpected and sometimes dangerous, results.

While I plodded my way through Craig’s course, my extracurricular life was stimulated by my residence in Crothers Memorial Dorm, fondly referred to as “Cro Mem”. It consisted of two buildings, side by side, one for graduate engineering and science majors and one for lawyers and MBA students. Although love was not great between the two buildings, there were frequent touch football games and mutual enjoyment of the promotional efforts of emerging wineries, like Wente Brothers and Inglenook, who provided free wine anytime we had a party, which was frequent. Judging from those I still know from Cro Mem, the wine promotion was very effective although maybe not for Wente and Inglenook. But parties required more than wine so we turned to the most innovative of the Cro Mem residents, Roger Melen. Roger arrived at Stanford with an undergraduate Electrical Engineering degree from, of all places, Chico State (Daniel Nenni: don’t take offense). He published a book titled “Understanding Operational Amplifiers” (which I didn’t) by his second year in graduate school and he was making money in a variety of entrepreneurial ways, like consulting for Bay Area electronics startups or writing articles for Popular Electronics. Whenever we needed money for a party, Roger generously wrote an article, received $400 and the party was on.

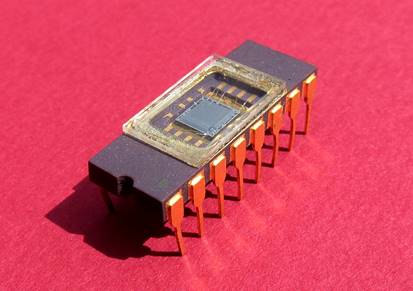

Image sensor made by Terry Walker, Roger Melen and Harry Garland

Meanwhile, Roger worked on his PhD thesis under Prof. Jim Meindl who had dozens of graduate students (many of whom came to make up the Who’s Who of the electronics industry) designing chips and producing them in the two-inch wafer fab on campus. Roger was working on the Optacon, a reading aid for the blind, developing an 8×16 pixel charge coupled device (CCD) for a compact version of the product. But Roger was much too innovative and productive to work only on his research. On the side, his consulting business had grown. He designed the electronics for all sorts of equipment that recent graduates were developing. Since most of these companies had very limited cash flow, Roger had to be content to accept future royalties in payment for some of his work. Over time, he discovered that these entrepreneurial customers, although skilled in engineering and product development, had lost the ability to count. Roger was concerned about being cheated on the royalties so he developed a system to overcome this deficiency. He performed the design work, as he always had, but instead of labeling the integrated circuits (IC’s) in the design, he and with his graduate student friend, Harry Garland, re-marked them with proprietary letters for one of the key IC’s in each design. He then assumed the supply chain fulfillment role by relabeling the IC’s and providing the parts for production.

Roger with fellow graduate student Harry created the name Cromemco, after the “Cro Mem” dorm, which in a few years became one of the very early, successful microprocessor based computers. They needed funding and publicity to start a company so Roger turned to his tried and true technique—writing articles for Popular Electronics but this time including the Cromemco name.

During this period, I completed my degree and headed to Texas Instruments where I was coincidentally assigned the task of developing CCD imagers. You can imagine our shock at TI when we saw a cover article of Popular Electronics entitled “Build Your Own Solid State Imager” by Roger Melen along with his graduate friends Terry Walker and Harry Garland. While Fairchild, Sony, RCA and TI competed fiercely to develop early CCD imagers, the graduate students at Stanford had beaten us to the punch. Or so we thought. The article provided circuit diagrams plus a block labeled “solid state imager”. To fill that block, the article instructed the reader to send a check or money order to Cromemco, which was actually just a student living in Crothers Memorial Dorm. For $25, Cromemco would provide the needed component. But instead of sending a CCD imager, Roger sent American Microsystems S4008-9 DRAM’s (this early DRAM did not automatically refresh the bits during readout and came in a ceramic package with a metal lid that could be replaced by a quartz lid) by popping the tops off the ceramic packages. The image quality was good enough for the hobbyists. Those $25 checks added up to over $50,000 and became critical seed money for Cromemco, which Roger and Harry sold in 1987.

20 Questions with Wally Rhines Series

Share this post via:

Flynn Was Right: How a 2003 Warning Foretold Today’s Architectural Pivot