At the recent TSMC Technology Symposium, TSMC provided a detailed discussion of their development roadmaps. Previous articles have reviewed the highlights of silicon process and packaging technologies. The automotive platform received considerable emphasis at the Symposium – this article specifically focuses on the automotive-related announcements.

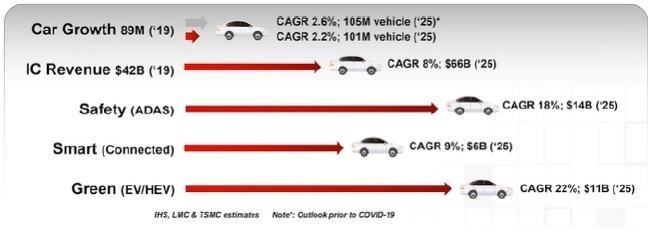

As illustrated below, the forecasts of semiconductor content in automotive designs show considerable and extended growth.

Advanced driver assistance systems (Level 4/5 autonomy) will experience high adoption in upcoming models, with extensive sensor integration, requiring significant increases in computational throughput for image processing and decision control.

TSMC described a number of process technology enhancements, ranging from high-voltage power management to microcontroller functionality to image sensors to (5G) wireless vehicle communication to advanced digital performance, all specifically for the “automotive grade” environment.

Review of Automotive Grades

The demanding and varied applications for the electronic control units and sensors in an automotive system necessitate specific definitions of environmental and reliability qualification specifications – in short, these are represented as different grades. AEC-Q100 is an industry standard specification that defines the specific qualification procedures:

-

- AEC-Q100 Grades

-

- Grade 0: -40C to 150C (automotive, under the hood)

- Grade 1: -40C to 125C (automotive)

- Grade 2: -40C to 105C (industrial)

- Grade 3: -40C to 85C (commercial)

-

- AEC-Q100 Grades

BCD Technologies for Automotive

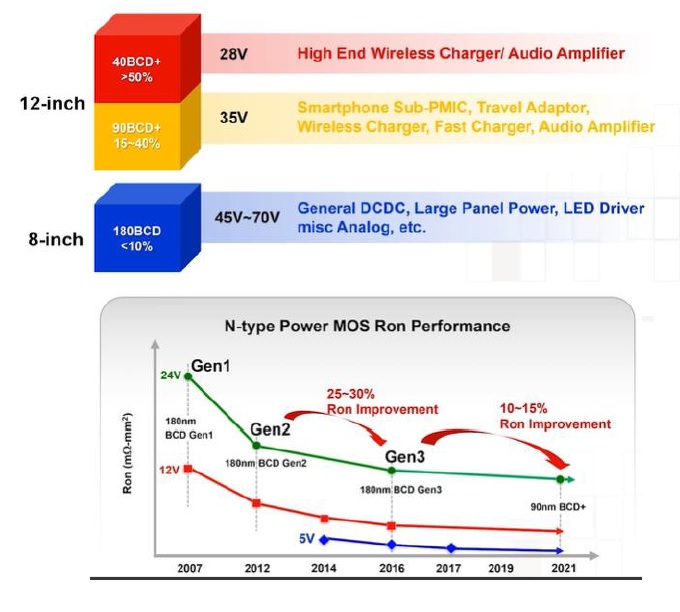

TSMC offers multiple families of BCD (Bipolar-CMOS-DMOS) technologies, in support of the different high-voltage domains within an automotive network, as illustrated below.

Continuing generational enhancements focus on reducing device on-resistance (Ron), to improve PMIC efficiency.

Embedded NVMs for automotive MCUs

Microcontrollers in automotive ECUs require embedded non-volatile memory blocks, for over-the-air (OTA) maintenance/feature updates. As the complexity of automotive electronic systems grows, MCUs will trend to newer process nodes for better PPA, and will require dense, high-reliability eNVM technology.

Key aspects of the eNVM reliability are the endurance cycle and data retention performance. The eNVM roadmap for the TSMC automotive platform is shown below.

At the N28 node, embedded flash memory is being qualified for Grade 0. Beyond the N28 node, magnetoresistive random access memory (MRAM) technology will be displacing eFlash. N22 MRAM is in high-volume production (Grade 1, 100K cycles, 10 years retention, and high-immunity to external magnetic field). N16 MRAM will be (Grade 1) qualified in 4Q22.

N5A

To address the computational requirement of (Level 4/5) data processing, TSMC is extending the production N5 process node to Grade 2 automotive qualification in 2022.

This N5A platform offering involves extending the design enablement support to Grade 2, from PDK models to TSMC library IP to aging/EM reliability analyses. Correspondingly, the TSMC OIP partners are working on extending their IP support to N5A, as well.

With regards to IP, the automotive platform is also required to demonstrate functional and electrical model quality plus safety features, through compliance with the ISO26262 standard, adhering to Automotive Safety Integrity Level (ASIL) specifications.

Clearly, the automotive platform is receiving significant R&D investment at TSMC, in anticipation of extended growth in the semiconductor MCU and sensor content in upcoming years. Increasing ADAS adoption and sales of EVs are driving a broad set of technology requirements, from PMICs to 5G RF wireless to high-end digital computation.

For more info on TSMC’s automotive platform, please follow this link.

-chipguy

Share this post via:

Comments

One Reply to “Highlights of the TSMC Technology Symposium 2021 – Automotive”

You must register or log in to view/post comments.