We are witnessing a significant revolution in automotive design. The software-defined vehicle is taking center stage as disruptive technologies are integrated into mass production. Areas such as autonomous driving, lighting, radar, and other camera-based sensors are all part of this revolution. AI is at the center of many of these changes, delivering continuous advancements in crucial applications such as Advanced Driver Assistance Systems (ADAS).

All this new technology presents many new challenges. Among them are lower power, higher performance and enhanced reliability. It turns out engineered substrates deliver substantial benefits in this environment. Soitec recently published a white paper that provides detailed information about these new trends and the benefits of its fully depleted silicon on insulator (FD-SOI) technology. A link is coming but first let’s explore some of the changes underway and how FD-SOI powers the future of AI in automobiles.

Architectures, Trends and Challenges

The diagram at the top of this post illustrates where Soitec substrates power AI in next-generation ADAS. Stepping back a bit, both the automotive radar and zonal controller markets are poised for significant growth, driven by advancements in AI and semiconductor technologies.

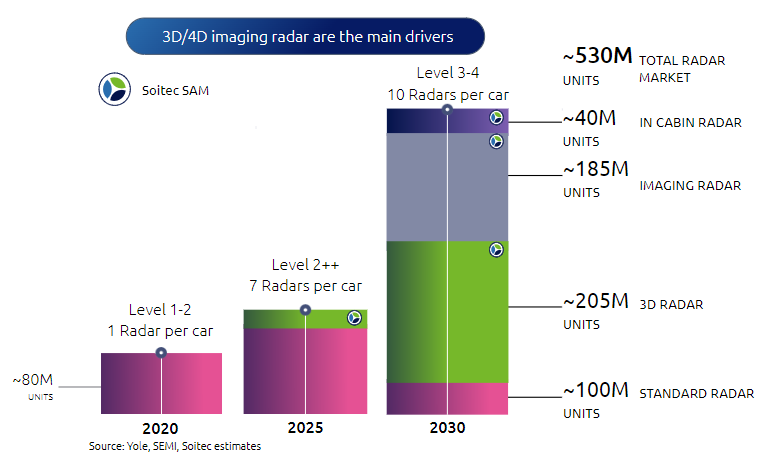

Automotive radar is projected to accelerate rapidly over the next decade. Starting with approximately 80 million units in 2020, mainly comprising Level 1-2 radar systems, each vehicle typically has one radar. By 2025, the market is expected to expand as Level 2++ systems, with around seven radars per vehicle, pushing the total to about 130 million units. By 2030, the market is projected to surge to roughly 530 million units, reflecting the growing prevalence of Level 3-4 systems, which could feature up to ten radars per vehicle.

These systems will be diverse, including in-cabin radar, imaging radar, 3D radar, and standard radar. Standard radar, which measures range and azimuth to detect the distance and direction of objects, is widely used in basic ADAS features like adaptive cruise control and emergency braking. 3D radar is crucial for applications like lane-keeping assistance, blind-spot monitoring, and detecting elevated obstacles, making it a key component of more advanced ADAS levels such as 2+ and 3. The figure below shows the projected growth of this market and the areas where Soitec technology has an impact.

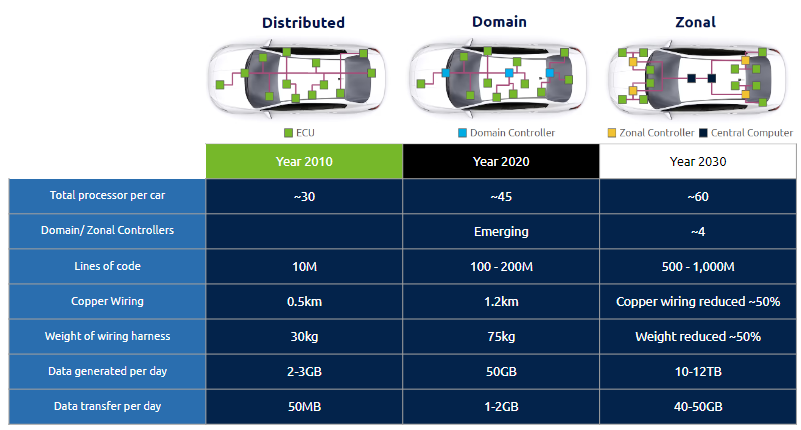

Regarding computing architectures, the traditional organization of electronic control units (ECUs) has been around a decentralized architecture, where each ECU handles specific functions within the vehicle independently. This “distributed ECU” architecture has been popular due to its flexibility and ability to isolate failures to individual ECUs. However, as vehicles become more complex with the advent of ADAS and autonomous driving, the industry is shifting towards more centralized and zonal architectures.

Centralized domain architectures consolidate computing power into fewer, more powerful ECUs or domain controllers, each managing a specific domain such as powertrain or infotainment. This reduces wiring complexity, enhances communication efficiency, and better manages the large data volumes associated with vehicle functions.

Zonal architectures represent the next step, grouping ECUs based on their physical location within the vehicle rather than their functional domain. This reduces wiring length, vehicle weight, and allows for more efficient power distribution and data management, although it increases software complexity. By 2030, vehicles are expected to partially embrace zonal architectures, significantly reducing copper wiring and harness weight, while supporting vast amounts of data generated by these new vehicles.

The diagram below depicts the projected growth of the zonal approach, along with the benefits and challenges this architecture presents.

With this background, let’s examine the impact FD-SOI can have.

FD-SOI and its Role to Power the Future of AI in Automobiles

Engineered substrates such as FD-SOI offer significant advantages for next generation automobiles. The key is how the industry can effectively harness FD-SOI to optimize AI in vehicles while maintaining energy efficiency. Soitec’s white paper provides substantial detail on the benefits of its engineered substrates for advanced automotive design. If advanced automotive design is on your horizon, or if you face challenges integrating AI in other types of systems, you will want to get a copy of this white paper. Let’s look at some of the topics that are covered.

By integrating Soitec’s advanced substrates, automakers can deliver more efficient, reliable, and intelligent driving experiences in the next generation of automotive technology. ADAS systems demand significant computational power to process large amounts of sensor data in real-time, requiring trillions of operations per second (TOPS) to perform tasks such as object detection, tracking, and decision-making simultaneously. Energy consumption is also a critical requirement here, as balancing high performance with low power consumption is essential to preserving range autonomy. This tradeoff between power consumption and performance creates a new form of requirement, measured in TOPs/Watt.

The white paper details many commercial applications that benefit from the superior TOPs/W delivered by Soitec’s FD-SOI technology. Details of the impact on Mobileye EyeQ4, NXP’s i.MX 8, STMicroelectronics’ Stellar MCUs, Lattice’s Nexus FPGA platform, and Bosch Radar are all provided.

The vast amounts of data that will be processed by zonal architectures is also discussed. For these systems, lines of code could grow exponentially to between 500 million to 1 billion. Copper wiring will likely be reduced by 50%, along with a 50% reduction in the wiring harness weight. The data generated per day could range between 10 to 12 terabytes, with daily data transfer expected to increase to 40-50GB. This starts to feel like a complex data center in every car.

In addition to reduced power and higher performance (TOPs/W), FD-SOI also offers enhanced reliability. Neutron-induced SRAM failures are discussed, illustrating the technology’s benefits. FD-SOI also offers superior performance with regard to aging effects. Substantial detail is provided on these and many other areas in the white paper.

To Learn More

I have just scratched the surface of the details provided in the new Soitec white paper. As mentioned, if advanced automotive design, or AI integration challenges in other applications are in front of you, this is required reading.

The white paper is titled Powering the Future of AI in Automobiles: FD-SOI’s Transformative Impact on ADAS and Zonal Architectures, and you can access your copy of the Soitec white paper here. And that’s how FD-SOI powers the future of AI in auto.

Also Read:

Soitec: Materializing Future Innovations in Semiconductors

EVs, Silicon Carbide & Soitec’s SmartSiC™: The High-Tech Spark Driving the Future (with a Twist!)

Share this post via:

Comments

There are no comments yet.

You must register or log in to view/post comments.