Siemens has strengthened its position in EDA and manufacturing by acquiring ASTER Technologies, a specialist in test and reliability solutions for printed circuit boards. The acquisition represents a strategic step in Siemens’ broader vision to deliver a fully integrated, end-to-end digital thread for electronics design,… Read More

Hardware is the Center of the Universe (Again)The 40-Year Evolution of Hardware-Assisted Verification — From…Read More

Hardware is the Center of the Universe (Again)The 40-Year Evolution of Hardware-Assisted Verification — From…Read More Smarter ECOs: Inside Easy-Logic’s ASIC Optimization EngineEasy-Logic Technology Ltd. is a specialized Electronic Design…Read More

Smarter ECOs: Inside Easy-Logic’s ASIC Optimization EngineEasy-Logic Technology Ltd. is a specialized Electronic Design…Read More The Name Changes but the Vision Remains the Same – ESD Alliance Through the YearsThe Electronic System Design Alliance (ESDA) has been…Read More

The Name Changes but the Vision Remains the Same – ESD Alliance Through the YearsThe Electronic System Design Alliance (ESDA) has been…Read More TSMC Process Simplification for Advanced NodesIn the modern world, the semiconductor industry stands…Read More

TSMC Process Simplification for Advanced NodesIn the modern world, the semiconductor industry stands…Read More CEO Interview with Juniyali Nauriyal of PhotonectJuniyali Nauriyal is the CEO and Co-Founder of…Read More

CEO Interview with Juniyali Nauriyal of PhotonectJuniyali Nauriyal is the CEO and Co-Founder of…Read MoreAgentic EDA Panel Review Suggests Promise and Near-Term Guidance

NetApp recently hosted a webinar on Agentic AI as the future for EDA and implications for infrastructure. Good list of panelists including Mahesh Turaga (VP Cadence Cloud) with an intro preso on infrastructure and agentic AI at Cadence, then our own Dan Nenni (Mr. SemiWiki) moderating, Khaled Heloue (Fellow AMD, CAD CAD/Methodology/AI),… Read More

Hardware is the Center of the Universe (Again)

The 40-Year Evolution of Hardware-Assisted Verification — From In-Circuit Emulation to AI-Era Full-Stack Validation

For more than a decade, Hardware-Assisted Verification platforms have been the centerpiece of the verification toolbox. Today, no serious semiconductor program reaches tapeout without emulation or FPGA-prototyping… Read More

Smarter ECOs: Inside Easy-Logic’s ASIC Optimization Engine

The Name Changes but the Vision Remains the Same – ESD Alliance Through the Years

The Electronic System Design Alliance (ESDA) has been at the center of the EDA industry through its many changes over the years. It occurred to me that an update on this organization would be useful. ESDA is a technology community within SEMI and is managed primarily by a team of three who coordinate all its activities along with a … Read More

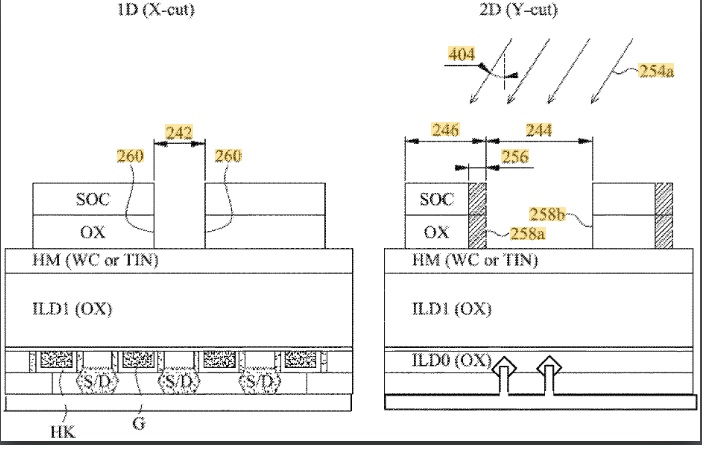

TSMC Process Simplification for Advanced Nodes

In the modern world, the semiconductor industry stands at the heart of technological innovation. From smartphones and laptops to advanced medical devices and artificial intelligence systems, nearly every piece of contemporary electronics depends on increasingly sophisticated microchips. Among the leading companies … Read More

CEO Interview with Juniyali Nauriyal of Photonect

Juniyali Nauriyal is the CEO and Co-Founder of Photonect, a photonics startup focused on commercializing advanced fiber-to-chip attachment technologies. Juniyali is the co-inventor of Photonect’s core technology, which forms the foundation of the company. As CEO, she leads Photonect in translating cutting-edge photonic… Read More

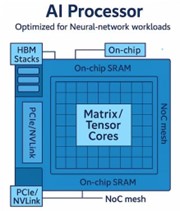

Podcast EP332: How AI Really Works – the Perspectives of Linley Gwennap

Daniel is joined by Linley Gwennap, technology analyst and author of the new book “How AI Really Works: The Models, Chips, and Companies Powering a Revolution.” Linley was the long-time editor of Microprocessor Report and chaired the popular Linley Processor Conferences.

Dan explores what impact AI is having on the market and… Read More

What is the 3nm Pessimism Wall and Why is it An Economic Crisis?

Chip design is getting more difficult as technology advances. Everyone knows that. A lot of the discussion around these issues tends to focus on the demands posed by massive AI workloads and the challenges of shifting to heterogeneous multi-die design. While these create real problems, there is an underlying effect that is making… Read More

CEO Interview with Aftkhar Aslam of yieldWerx

Aftkhar Aslam is the Co-Founder and Chief Executive Officer of yieldWerx and a semiconductor industry veteran with more than 30 years of experience spanning manufacturing, test engineering, yield management, IP strategy, and enterprise digital transformation.

Under his leadership, yieldWerx has become a trusted data and… Read More

The Name Changes but the Vision Remains the Same – ESD Alliance Through the Years