- This event has passed.

Product Qualification Overview

February 5

Package reliability and qualification continue to evolve with the electronics industry. New electronics applications require new approaches to reliability and qualification. In the past, reliability meant discovering, characterizing and modeling failure mechanisms, and determining their impact on the reliability of the circuit. Today, reliability can also involve tradeoffs between performance and reliability; assessing the impact of new materials; dealing with limited margins, and other factors. In particular, the proliferation of new package types can create difficulties. This requires information on subjects like: statistics, testing, technology, processing, materials science, chemistry, and customer expectations. Customers expect fast, smooth qualification, but incorrect assumptions, use conditions, testing, calculations, and qualification procedures can severely impact this process. Your company needs competent engineers and scientists to help solve these problems. Product Qualification Overview is a 1-day course that offers detailed instruction on a variety of subjects pertaining to semiconductor reliability and product qualification. This course is designed for every manager, engineer, and technician concerned with qualification in the semiconductor field, qualifying semiconductor components, or supplying tools to the industry.

What Will I Learn By Taking This Class?

Participants will learn to develop the skills to determine the best process for qualification; how to identify issues; and how to resolve them. This skill-building series is divided into four segments:

- Qualification Principles. Participants will learn how test structures can be designed to help test for a particular failure mechanism.

- JEDEC Qualification. Participants will learn how to perform a Joint Electron Device Engineering Council (JEDEC) Standard 47 Qualification. We will cover the overall procedure and introduce the individual tests. We will also discuss items related to requalification.

- AEC Q-100 Qualification. Participants will learn how to perform an Automotive Electronics Council (AEC) Q-100 Qualification. We will cover the overall procedure and introduce the individual tests. We will also discuss the important differences between the AEC Q-100 Qualification process and the JEDEC Qualification process.

- JEDEC Tests. Participants will learn about the JEDEC tests. We will cover the more important individual tests used in the qualification of semiconductor components. These tests are common to both the JEDEC and AEC standards.

Course Objectives

- This course will provide participants with an in-depth understanding of the failure mechanisms, equipment, and testing methods used to qualify today’s components.

- Participants will be able to gather data, determine how best to plot the data and make inferences from that data.

- This course will identify major failure mechanisms; explain how they are observed, how they are modeled, and how they are handled in qualification.

- This course will discuss the major qualification processes, including JEDEC JESD47, AEC Q-100, and other related documents.

- Participants will be able to identify the steps and create a basic qualification process for semiconductor devices.

- Participants will be able to knowledgeably implement additional tests that are appropriate to assure the reliability of a component.

- Participants will be able to identify appropriate tools to purchase when starting or expanding a laboratory.

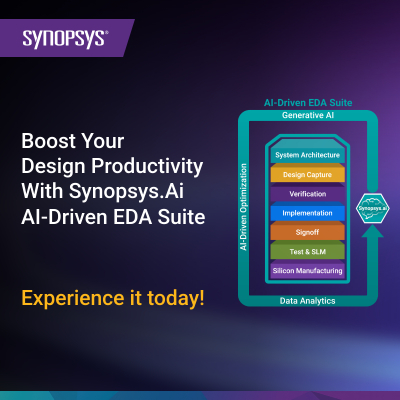

Achieving Seamless 1.6 Tbps Interoperability for High BW HPC AI/ML SoCs: A Technical Webinar with Samtec and Synopsys