When I think about servers and data centers, I think about multiple-core/high-power CPUs, Intel’s domination over the years and GPUs coming on strong in recent years. I think about very fast digital interfaces, such as PCI Express connections and the latest DDR memory interface. Precision analog isn’t something that first comes to mind. But it’s there, with one of the larger cloud computing companies, if you look closely enough.

One of my favorite aspects of 20 years in the semiconductor industry is the job of new product definition. Finding a market need for a new analog mixed signal device, especially in this era with tens of thousands of integrated circuits, is definitely not easy. In this case study, our product definition started with a great relationship between our sales team and the customer. Based on the level of feedback we were able to get, the account manager and field apps engineer clearly earned the trust of the lead designer at this cloud computing customer.

In data centers, “metered power” has become one of the common ways of charging their end customers for usage. Fixed costs for power allocation are common by the rack. In more recent years, a new “pay for use” pricing model has emerged. By pricing for allocated power and reserved cooling capacity, cloud computing companies and their end customers can reduce overbuilding and overpaying.

In our customer example, we learned this designer needed to accurately measure power in order for the cloud computing company to accurately bill their end customers down to their milliseconds (or maybe even microseconds) of server power usage. As the business manager of the amplifier product line, I got pulled into the conversation. We initially discussed using a 1milliohm shunt resistor, an existing current sense amplifier and measuring the amplifier output with a microcontroller’s ADC. The MCU also had an integrated multiplexer in front of the ADC. The designer’s original thought was to use our current sense amplifier through one mux channel and measure the voltage with another channel.

Measure current. Measure voltage. Calculate power in the digital domain. Simple, right?

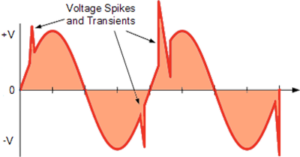

But not so fast. After some reflection from my product definer, along with the customer, we thought about the use case of transient responses. With those complex CPU functions, GPU functions, memory reads and writes and high-speed digital interfaces, the transients and load steps could be pretty nasty. With each ADC measurement and power calculation, they’d have to account for the delay through the multiplexer between the voltage and current readings. In a slow moving or steady state current load, they’d be fine. But with fast moving transients, both sides came to the conclusion that a power multiplier/amplifier was needed. The power amplifier calculated instantaneous power by multiplying the load current across a sense resistor by a fraction of the voltage set by an external resistive divider in order to produce a true power output from the amplifier.

Another interesting product differentiation was providing a current out of the power amplifier. Nearly every other amplifier and current sense amplifier provides a voltage output. In this customer’s case, the power amplifier was located on the server board a long distance away from the MCU with the integrated ADC. Similar to the principle behind 4-20mA industrial current loops, the current output from the power amplifier eliminates any errors caused by voltage drops across the parasitic resistance of the PCB, which is often significant for high-current systems. With a simple resistor to ground at the mux/ADC input, the customer could convert the current to voltage and get accurate, fast readings representing instantaneous power.

In the end, the data center company could accurately measure the power drawn and bill their customers accordingly. They designed in our power multiplier. And they clearly cared about what they were measuring.

Part I The Question That Has Guided My Analog Mixed Signal Career

Share this post via:

Flynn Was Right: How a 2003 Warning Foretold Today’s Architectural Pivot