According to McKinsey & Company, a digital twin is a digital representation of a physical object, person, or process, contextualized in a digital version of its environment. Digital twins can help an organization simulate real situations and their outcomes, ultimately allowing it to make better decisions. Anyone who is a fan of the shift-left development methodology will immediately see the benefits a digital twin offers. The shift-left approach aims to take tasks that are typically done later in the design process and perform them earlier, creating forward visibility and less chance for re-work. While the shift-left strategy has been around a while, commercial deployment of digital twin models that are robust enough to make an impact is newer. A recent announcement illustrates a high-impact deployment of a digital twin for automotive design and illustrates the collaboration required for success. Read on to see how Siemens Digital Industries Software collaborates with AWS and Arm to deliver an automotive digital twin.

According to McKinsey & Company, a digital twin is a digital representation of a physical object, person, or process, contextualized in a digital version of its environment. Digital twins can help an organization simulate real situations and their outcomes, ultimately allowing it to make better decisions. Anyone who is a fan of the shift-left development methodology will immediately see the benefits a digital twin offers. The shift-left approach aims to take tasks that are typically done later in the design process and perform them earlier, creating forward visibility and less chance for re-work. While the shift-left strategy has been around a while, commercial deployment of digital twin models that are robust enough to make an impact is newer. A recent announcement illustrates a high-impact deployment of a digital twin for automotive design and illustrates the collaboration required for success. Read on to see how Siemens Digital Industries Software collaborates with AWS and Arm to deliver an automotive digital twin.

Building a Digital Twin – PAVE360™

Announced in 2019, PAVE360 from Siemens aims to deliver a “revolutionary new validation program to accelerate autonomous vehicle development.” Today, the product delivers digital twin technology intended to put a virtual car on every engineer’s desk. The goal is robust pre-silicon validation for software-defined vehicle designs – the Holy Grail of the shift-left methodology.

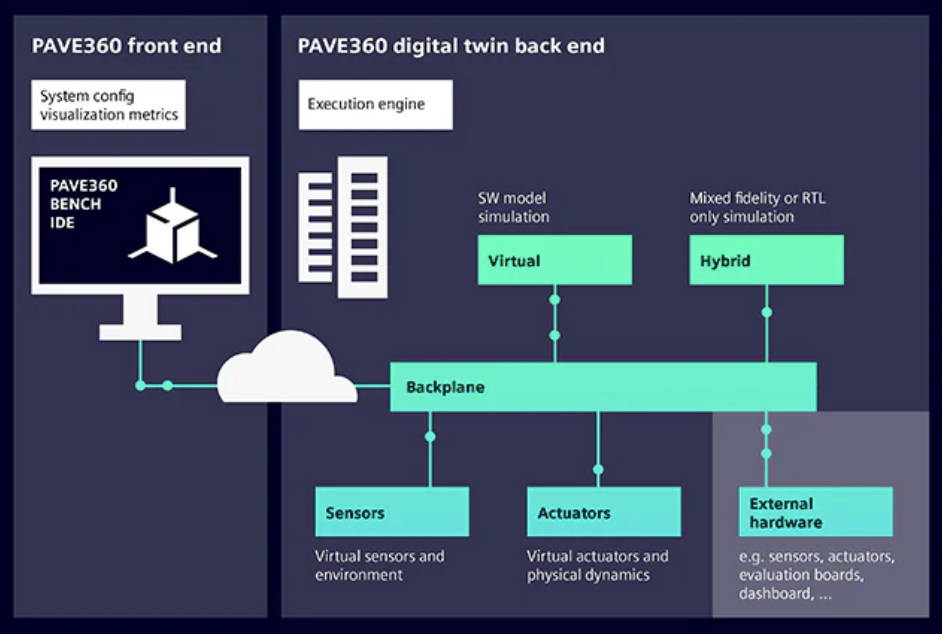

PAVE360 delivers some important capabilities to enable this goal, including:

- An open platform – allowing configuration and connection of mixed fidelity domains, protocols, systems and tools from multiple sources. This allows adapting digital twin models for each phase of the vehicle design cycle.

- A consistent environment – facilitating full “system-of-system” results with in-depth performance metrics.

- The ability to start with your existing tools – you can connect available models and then test the system. This makes it easier to analyze metrics to improve and iterate on the design for faster decisions.

- Access to mixed-fidelity analysis – using hybrid simulation, mixing virtual and register transfer level (RTL) code to deliver greater accuracy.

- Create a virtual car – you can model SoCs, ECUs or full system-of-systems. This allows you to maintain consistency and break down silos as multiple teams work on the same digital twin.

The figure below is an overview of PAVE360.

You can get a full over of PAVE360 here.

The Power of Collaboration

A digital twin has a lot of moving parts. Items like accurate, mainstream models and robust compute infrastructure to support all the analysis required are two good examples. Recognizing this, Siemens Digital Industries got to work with a couple of their partners to address the holistic requirements of digital twin technology. A recent announcement outlined the details of the company’s plan.

Expanding on the strong partnership between Siemens and AWS, PAVE360 is now available on the cloud. By using the AWS technology, developers can experience near real-time simulation speeds which are significantly faster than conventional on-premises modeling and simulation infrastructures. This partnership improves both time-to-market and quality of results since the right compute infrastructure can be deployed when needed to ensure fast, robust and accurate results.

Siemens has also collaborated with Arm to help enable developers to access Arm®-based technology running on Siemens’ PAVE360 Digital Twin solution via AWS cloud services. Automakers are now able to develop software and evaluate key Arm-based system and software components earlier in their IP selection and design cycles, without the burden of conventional on-premises software.

The program not only helps address the technology and commercial challenges ahead but also helps empower developers to gain a competitive advantage by shifting left hardware and software development, with unprecedented simulation speeds, enabling them to meet shrinking time-to-market requirements. Executives from AWS and Arm also weighed in:

“The proliferation of digital twin methodologies throughout the automotive industry uses the compute capabilities and world-class infrastructure of AWS,” said Wendy Bauer, Vice President of Automotive and Manufacturing, AWS. “With PAVE360 mapping accurate embedded environments to optimal AWS instances while using Arm automotive enhanced IP, OEMs and suppliers are enabling software defined vehicle solutions and methodologies that were previously impractical.”

“The software defined vehicle is survival for the automotive industry, requiring new technologies and methodologies for faster and more agile development,” said Dipti Vachani, Senior Vice President and General Manager, Automotive Line of Business, Arm. “The innovative Siemens’ PAVE360 solution is helping to accelerate the automotive system development required to address the increasingly demanding consumer expectations. Together with Siemens and AWS, we are enabling a breadth of use cases on the Arm automotive platform across the entire supply chain, from IP evaluation to fleet management.”

To Learn More

You can hear more about the impact of digital twin technology on automotive design at the upcoming IESF Automotive E/E Design & Engineering Conference. The event will take place in Munich, Germany on November 30, 2023. You can learn more about the conference and register here. And that’s how Siemens Digital Industries Software collaborates with AWS and ARM to deliver an automotive digital twin.

Share this post via:

Comments

There are no comments yet.

You must register or log in to view/post comments.