So much has changed over the recent couple of decades in what constitutes an automobile. Gone are the days when it was essentially an electro-mechanical product, used for just personal transportation. Over the years, it has evolved to adding in-cabin infotainment, tele and data communications, driving assistance, all the way to autonomous driving experience. All of these are of course made possible with electronics powered by semiconductor chips. And, with the migration away from internal combustion toward electric-motor powered automobiles, vehicle maintenance needs as we have traditionally known have come down.

At the same time, the need for a different kind of monitoring has been on the rise, with an eye on vehicle maintenance. The hardware and software components of automobile electronics need to be monitored and maintained to ensure safe and reliable driving experience. The traditional approach would be for periodic maintenance of the vehicle based on a predefined time schedule to check/replace electronic components and update embedded control software. But with current and future automobiles relying so much on electronics to operate, unforeseen catastrophic failure of critical electronics could lead to a fatal accident and cause lot of collateral property damage. A better approach is needed for maintaining vehicles of the future.

Recently, proteanTecs and HARMAN published a joint whitepaper that describes a novel approach and an effective solution for maintaining vehicles of the future. This blog will cover some salient points from the whitepaper and how the joint solution will help in maintaining the vehicles of the future.

Software Defined Vehicle (SDV)

SDV is the direction the automobile industry has been rapidly moving toward. SDVs are automobiles designed to be controlled by software to make the vehicles operate more efficiently and safely and to make vehicle maintenance easier. While SDVs bring these benefits, they throw some challenges too. Any failure in a SDV must be addressed quickly and effectively to avoid additional damage by the SDV and to the SDV. If possible, any operational failure of a SDV should be pre-empted.

The proteanTecs-HARMAN Solution for Maintaining Vehicles

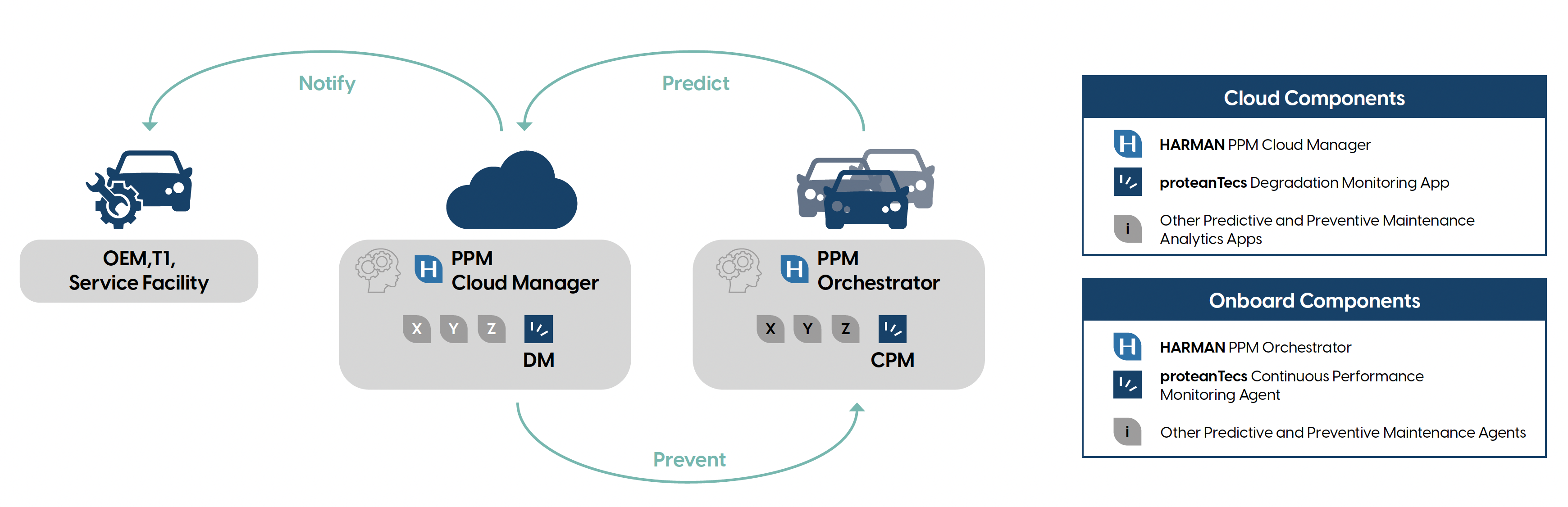

HARMAN and proteanTecs have jointly developed a predictive and preventive maintenance (PPM) solution that can detect potential faults in a vehicle’s systems. The solution can take pre-emptive measures to predict and avoid catastrophic issues. It leverages proteanTecs’ proprietary advanced device health monitoring and deep data analytics to create, extract and analyze deep data from within SoC devices. The results provide insights into Electronic Control Unit (ECU) health, enabling vehicle manufacturers to monitor performance, pinpoint fault sources and predict Time to Failure (TTF). The total solution integrates HARMAN’s embedded security, in-vehicle analytics, cloud-to-vehicle connectivity and over-the-air (OTA) updates. The end result is an effective solution that meets safety and reliability requirements of SDVs. The following two applications are key components of the solution.

Continuous Performance Monitoring (CPM) Application

The CPM application delivers real-time monitoring of device and board electrical performance indicators of onboard system electronics. As an edge application, it lowers operational and security risks by detecting faults close to the failure.

Degrading Monitoring (DM) Application

The DM application is essentially a sub-function of the CPM application, designed to predict the Time to Failure (TTF) and the Remaining Useful Life (RUL). It does this by measuring Key Performance Indicators (KPI) degradation and the frequency of occurrence. These predictions are made available to the Predictive and Preventive Maintenance (PPM) Cloud Manager to trigger scheduling services and shipment of parts.

Some Use Cases

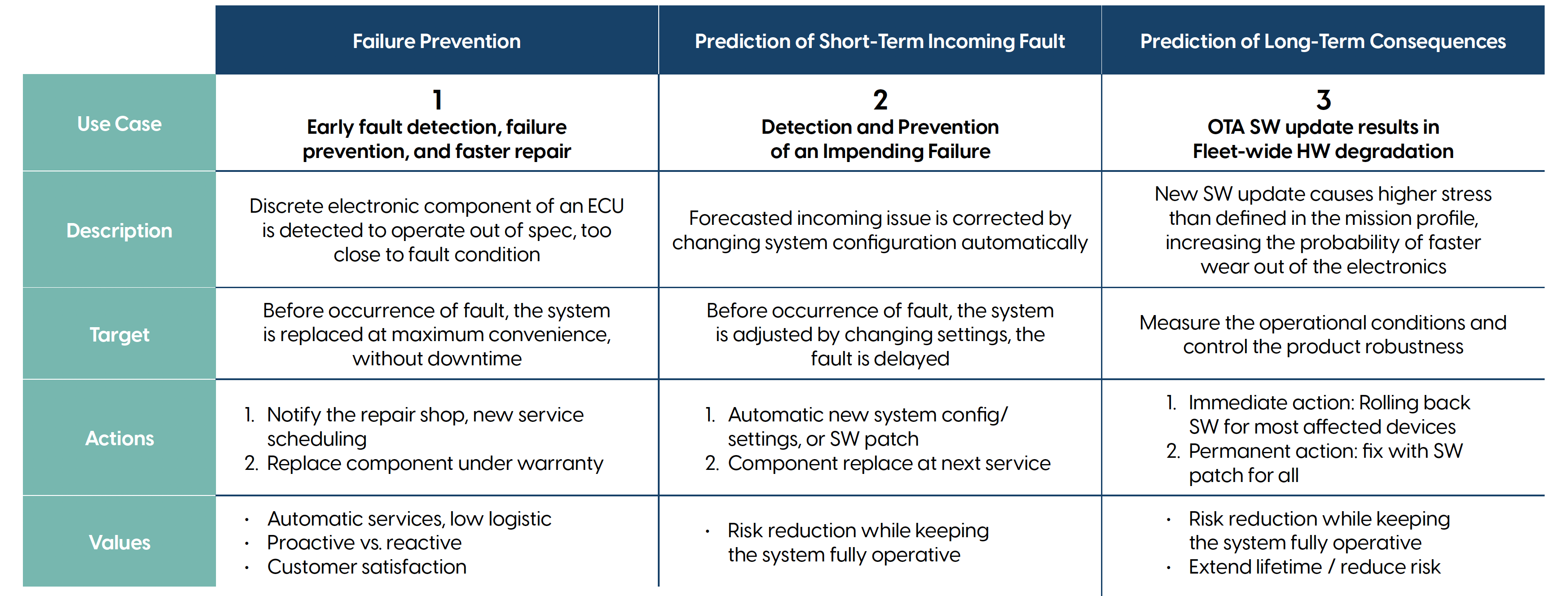

The whitepaper also presents a use case for failure prevention, one for prediction of short-term incoming fault and another for prediction of long-term consequences. The benefits of these use cases are obvious. The whitepaper goes into lot of details about each of these three use cases. For more details, refer to the whitepaper.

Summary

The HARMAN-proteanTecs collaboration offers a platform for automobile manufacturers to detect faults before they become failures and fix the faults through OTA techniques. The platform incorporates an industry first Time-to-Correction technique and can scale with the growing complexity of SDVs. The solution helps reduce downtime and maintenance costs, improve customer satisfaction and reduced vehicle recalls. Anyone involved in developing hardware and software solutions for SDVs would benefit from reviewing the entire whitepaper.

You can download the whitepaper here.

Also Read:

Webinar: The Data Revolution of Semiconductor Production

proteanTecs Technology Helps GUC Characterize Its GLink™ High-Speed Interface

Elevating Production Testing with proteanTecs and Advantest’s ACS Edge™ Platforms

Share this post via:

TSMC vs Intel Foundry vs Samsung Foundry 2026