When AMD announced its cutbacks recently many people were left wondering why they were so deep given the strong financial performance in Q3 and the guidance for an up Q4. It couldn’t have been related to the Thailand floods that could have been at most a one-quarter squeeze expected in Q1. Now it is apparent from reports that AMD’s cutbacks were based on the cancelling of its 28nm APUs at Global Foundries and the time required to move to TSMC. The change will significantly delay new APU (CPU+graphics) offerings to address the low cost and “ultrabook” markets. Many companies, especially startups, choose a path that leads to Crossing a Chasm in order to be successful. Since Dirk Meyer’s exit at the beginning of the year, market forces and trends for 2012 are requiring that AMD enter a startup mentality mode and thus have to Cross a Chasm not of its own volition.

Continue reading “AMD’s Crossing of the Chasm”

What happens in Las Vegas Gets Blogged on SemiWiki!

Interesting story, for my wife’s 50th birthday we went to Las Vegas to see Sir Elton John in concert. My wife is an Elton fan and this may be her last chance to see him live so off we went. I saw Elton and Billy Joel in a dueling piano concert a while back and it was simply amazing! The underlying purpose of the trip however was to earn “Perfect Husband Points” (PHP’s), which can then be traded in for sailing trips in Mexico etc… Right now I’m saving up for a trip to Spain to run with the bulls.

When we checked in ( Caesar’s Palace Las Vegas ) the desk lady asked us which part of the hotel we would like to stay in. We could be near the registration desk for convenience, or we could be near the topless pool, or be near the chapels. Without hesitation, I said near the chapels please (+1,000 PHP’s). Okay, I may have hesitated briefly, but come on, who knew there would be a topless pool!

After getting settled in our suite (500+ PHP’s) we took a walk around the hotel and stopped by the chapels to see what a wedding at Caesar’s is all about. There were three chapels one large, one medium, and one small, all very beautiful! The wedding coordinator told us that a marriage renewal costs $350.00 and included a quick service in the small chapel and a decorative certificate. So I got down on one knee and asked my wife to marry me again (+5000 PHPs) and luckily she said yes.

The wedding coordinator then told us that a deluxe wedding had just cancelled and if we could be ready at 6pm (1+ hour) we could have it for the $350.00 price we already agreed to! Such a deal! The large chapel, flowers, champagne, pictures, all inclusive, how could we pass that up! (+1000 PHP’s)

Strangely enough we were both nervous even after being together for 30+ years. Even stranger, she did not cry at our first wedding but she cried tears of joy at this one as the picture shows. I didn’t cry, probably because I was more focused on the honeymoon part. We even bought a new ring for me which I have not taken off since (+2000 PHP’s).

The Elton John “Million Dollar Piano” concert was outstanding, he is still quite the showman. His piano probably cost a million dollars, thus the name. The piano was four years in the making, is covered with 68 LED screens, and weighs 3,200 pounds! The piano lit up with color and imagery to reflect the theme of each song, it was amazing! Such technology! Brought to you by the semiconductor design and manufacturing ecosystem!

The other technology that was glaring in our faces were the smartphones that people held up to take pictures and video of the event. Of course we were constantly reminded that photos and video were NOT allowed but the majority of people did it anyway. Another example of smartphone inspired anarchy!

How to use NoC to avoid routing congestion

Network-on-Chip (NoC) is an emerging paradigm for communications within large VLSI systems implemented on a single silicon chip. Sgroi et al. call “the layered-stack approach to the design of the on-chip intercore communications the Network-on-Chip (NOC) methodology.” In a NoC system, modules such as processor cores, memories and specialized IP blocks exchange data using a network as a “public transportation” sub-system for the information traffic. A NoC is constructed from multiple point-to-point data links interconnected by switches (a.k.a. routers), such that messages can be relayed from any source module to any destination module over several links, by making routing decisions at the switches. A NoC is similar to a modern telecommunications network, using digital bit-packet switching over multiplexed links. Although packet-switching is sometimes claimed as necessity for a NoC, there are several NoC proposals utilizing circuit-switching techniques. This definition based on routers is usually interpreted so that a single shared bus, a single crossbar switch or a point-to-point network are not NoCs but practically all other topologies are. This is somewhat confusing since all above mentioned are networks (they enable communication between two or more devices) but they are not considered as network-on-chips. Note that some articles erroneously use NoC as a synonym for mesh topology although NoC paradigm does not dictate the topology. Likewise, the regularity of topology is sometimes considered as a requirement which is, obviously, not the case in research concentrating on “application-specific NoC topology synthesis”.

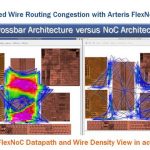

An interesting white paper from Arteris: “Routing Congestion: The Growing Cost of Wires in Systems-on-Chip” demonstrates how you can drastically reduce routing congestion by using a NoC. On this picture, you can see on the left part, the routing congestion areas, highlighted through a color code (purple= very strong congestion, red=strong congestion, yellow=medium, blue=no congestion), this will sounds familiar to anybody who has already used a floor planning tool. According with Jonah Probell: “…in the process of chip design, more can be done to improve P&R wire congestion by reducing the number of wires in the IP RTL before synthesis.”

For those like me who have used floor planning tools in the mid 90’s, to help customers to release to layout the RTL version of a chip with good chance to complete the lay out phase within a decent time period (say, a couple of weeks, as these chips were designed into a supercomputer, using the largest available BiCMOS base array, running at the highest possible internal frequency, which makes sense when you design a supercomputer…), it was common to spend weeks if not MONTHS to optimize the floor plan of the IC. I realize now that having the opportunity to use a NoC at that time would certainly help us to, either reduce the design cycle (thus the Time To Market for our customer, as well as the time spent by TI FAE team), either go higher in frequency, and help our customer to launch a more powerful product. I strongly encourage anybody involved (or interested) by on the edge SoC design techniques to download this paper from Arteris here.

Eric Esteve from IPNEST

Reducing the Need for Guardbanding Flash ADC Designs

Flash analog-to-digital converters (ADCs) are commonly used in high-frequency applications such as satellite communications, sampling oscilloscopes, and radar detection. Flash ADC is preferred over other ADC architectures because it is extremely fast and quite simple. However, flash ADC typically requires twice as many converters per bit for higher accuracy requirements, which increases the size of the chip (and likewise the cost).

Not surprisingly, at small process nodes, the influence of parasitic elements on these sensitive mixed-signal designs is growing, due to the increasing interactions between devices and interconnects that are in close proximity. Circuits are highly sensitive to these parasitic effects, so accurate parasitic extraction is critical for first silicon success.

Constraints used to lay out a flash ADC are also extremely important, because differential pairs must have symmetrical layouts, identical capacitors must have equal values, and resistors must be matched. For example, if one resistor must be over-etched because of process variation sensitivity, all of the resistors must be over-etched in the same way to ensure that the taps off the resistor ladder are still the correct voltage value. Several guidelines can help improve layout matching.

Designing flash ADCs requires careful tradeoffs between speed, accuracy, and power. Highly accurate parasitic extraction ensures that parasitics will not cause the ADC to behave incorrectly, and that the ADC will still meet all of the design specifications.

New 3D parasitic extraction technology applied to a flash ADC circuit design reduces the need for extra guardbanding, while ensuring the circuitry will work according to the specifications when manufactured.

You can download the complete “Reducing the Need for Guardbanding a Flash ADC Design” whitepaper HERE.

About the Author:

Karen Chow is the Technical Marketing Engineer for Calibre xRC and Calibre xACT 3D at Mentor Graphics in Wilsonville, OR. She has worked on both sides of the EDA industry, designing analog ICs and supporting EDA tool development. Karen has her BSc in electrical engineering from the University of Calgary, and her MBA from Marylhurst University. In her spare time, she enjoys playing music in bands, designing clothing and handbags, and quilting.

var _gaq = _gaq || [];

_gaq.push([‘_setAccount’, ‘UA-26895602-2’]);

_gaq.push([‘_trackPageview’]);

(function() {

var ga = document.createElement(‘script’); ga.type = ‘text/javascript’; ga.async = true;

ga.src = (‘https:’ == document.location.protocol ? ‘https://ssl’ : ‘http://www’) + ‘.google-analytics.com/ga.js’;

var s = document.getElementsByTagName(‘script’)[0]; s.parentNode.insertBefore(ga, s);

})();

David Liu, Kauffmann Award winner

David Liu receeived the Kaufman award for 2001 at the Kaufman award dinner a few weeks ago.

Or to be more formal about it:Dr. C. L. David Liu, the William Mong honorary chair professor of Computer Science and former president of the National Tsing Hua University in Hsinchu, Taiwan, will be presented with this year’s Phil Kaufman Award for Distinguished Contributions to Electronic Design Automation (EDA). Dr. C. L. David Liu, the William Mong honorary chair professor of Computer Science and former president of the National Tsing Hua University in Hsinchu, Taiwan, will be presented with this year’s Phil Kaufman Award for Distinguished Contributions to Electronic Design Automation (EDA).

Dr Liu started his career in Taiwan before coming to the US for an extended period and then returning to Taiwan where he continues to be very active in both academic circles and with his own radio program (unfortunately only in Chinese). As he says, he’s a 70 year old guy living the life of two 35 year olds. Reminds me of that line when Mac is told he can’t have a 42-year old scotch that night. “Give me 4 8-years olds and a 10-year old”.

Jason Cong presented the award. David was Jason’s PhD advisor. And not just Jason’s, a long list of people who have gone on to make significant contributions to EDA. One name I recognized and hadn’t known about was Anmol Mathur, who worked for me at Ambit over a decade ago and has since founded Calypto where he continues to be the CTO.

If there is one thing that characterizes David’s contributions to EDA, I think it is giving heuristic algorithms rigorous foundation, or coming up with rigorous algorithms from scratch. He made major contributions in slicing floorplans, over-the-well channel routing, performance driven placement, scheduled resource sharing, optimal clock period FPGA technology mapping and rate monotonic scheduling. These are not just algorithms of historical significance, they are used inside moder EDA tools. Ajoy Bose, CEO of Atrenta, gave credit for using some of his work in SpyGlass physical. Chi-Foon Chan, COO of Synopsys gave credit for his ideas directly benefiting Astro and IC compiler. And his scheduling algorithms are used in today’s cell-phones.

In 1968 David Liu wrote “Introduction to combinatorial mathematics.” Remember this was before the concept of NP-completeness had been introduced, so very early in the development of combinatorial mathematics and complexity.

Perhaps most surprising of all is that since 2005, David Liu has done a weekly talk show covering all sorts of aspects of technology such as the founding of Google, Steve Jobs’ now famous Stanford commencement speech.

Congratulations to David Liu.

Multi-Mode Simulation – What’s New at Cadence?

Every week I receive several webinar invitations, so the recent one from Cadence about Virtuoso Multi-Mode simulation caught my fancy because I had met with John Pierce at DAC and wanted to see what was new since then and see how they compared with Mentor and Synopsys tools.

John Pierce, Product Marketing Director

This webinar runs 41 minutes and here’s what I learned:

Analog/RF Design Challenges

My favorite example is the migration to SmartPhones that now support many radios: GSM, GPRS/EDGE, UMTS/HSDBA , WLAN, GPS, Bluetooth. Last year as a late adopter I bought my first SmartPhone from Samsung, the popular Galaxy and quickly learned how limited the battery charge lasted. I’m pleased that this year I’ve upgraded to the Samsung inFuse and seen my batter life improve from just one day to two days between charges, even when the screen size went from 4.0″ up to 4.5″.

ADC Design Trends

Chip designers have tighter specs when choosing or designing analog IP, parasitics impact performance more than previous nodes, and this all leads to larger circuits that take much more simulation time for both design and verification.

MMSIM Features

- foundry qualified/supported models for SPICE

- cell and memory characterization (from Altos)

- SPICE with digital, SI, PCB, RFIC and EM/IR

Spectre/Spectre RF

Make convergence and accuracy the top goals. Accept languages like: Verilog A, SpectreMDL. Support RF analysis and simulate with millions of extracted RC elements.

APS

The Accelerated Parallel Simulator can be used to reduce simulation runtimes by adding more cores in a linear fashion:

Multiple machines in a cluster are supported with: LSF, rsh, ssh, SUN GRID, Loadleveler:

Even RF simulation completes faster in APS for Shooting Newton and Envelope Analysis:

MMSIM 10.1 Release

APS got faster, RF advanced analysis added, reliability analysis added, distributed processing for faster simulation times.

UltraSim with hierarchy simulation handles an EMIR flow.

Demo by Rich Davis

Transient analysis simulation started in Analog Design Environment (ADE) using Spectre:

Same netlist was then rerun using APS on a single core, elapsed time of 6.1 seconds compared to Spectre taking 88 seconds, no loss of accuracy.

Spectre and APS waveform results compared

Use multi-threading and distributed simulation only on larger circuits.

User can trade-off between accuracy and run times, here’s what happened when accuracy was loosened up the run time reduced from 6.1 to 4 seconds:

Faster but less accurate results in APS, you decide

The second APS demo circuit was bigger with 1.45 million nodes and 3+ million BSIM devices, APS, multi-threaded with 8 cores, 24K time points, ran in 4 hrs 2 minutes 52 seconds.

The third demo circuit showed Transistor-level Envelope which simulated in 52 minutes, then Fast Envelope was simulated in under 20 seconds using pre-characterized behavioral models:

Error Vector Magnitude plotting was shown on an output node in just a few seconds:

Harmonic balance simulation results were demonstrated next on an amplifier circuit as Loadpull results where input magnitude and phase were varied across a large range in about 1 minute of time:

The final simulation showed HB noise results on a large inductor values:

Summary

It looks like Cadence has followed the parallel approach started by Magma’s FineSim SPICE and FineSim Pro. Magma doesn’t have their own HDL simulator, so Cadence’s approach is better if you have to simulate SPICE netlists with VHDL, VHDL-AMS, Verilog-A, Verilog-AMS or Verilog.

Cadence offers UltraSim which handles hierarchy, so they’re ahead of Mentor in that regard because ADiT and Eldo are flat simulators.

Synopsys has hierarchical and parallel SPICE simulation, so they go head-to-head with Cadence in this same product area.

You still have to evaluated each circuit simulation vendor on your own designs to determine if it’s best for you:

- Speed

- Accuracy

- Capacity

- Integration

- Analysis

- Netlist compatibility

- Learning curve

- Price

GlobalFoundries’ Expansion on Hold! Trouble in Abu Dhabi?

When AMD sought to shed its costly manufacturing operations, Ibrahim Ajami saw an interesting opportunity, one that promised to bring semiconductor manufacturing to Abu Dhabi. Let’s start with the January 2010 interview with Ajami, the 35 year old Chief Executive Officer of Advanced Technology Investment Company (ATIC), which is owned by the Government of the Emirate of Abu Dhabi, the controlling shareholder of GlobalFoundries (GFI).

GlobalFoundries wants 30% of the made-to-order chip market within three years. “Am I setting very aggressive targets? Yes,” Ajami said in a Jan. 28, 2010 interview in Abu Dhabi. “We need to be a $5 billion company in the next two to three years.” A 30% share would take GFI well past United Microelectronics Corp (UMC), making it the world’s second-largest contract manufacturer of chips after Taiwan Semiconductor Manufacturing Co (TSMC).

As I mentioned in TSMC versus GlobalFoundries Part I and Part II, GFI is attempting to compete head-to-head with TSMC in the first source semiconductor market, while UMC and SMIC are content to be second and third source semiconductor manufacturers. GFI has not been shy about their challenge to TSMC’s wafer supremacy and TSMC has responded in kind by increasing capital expenditures, increasing R&D expenses, and hiring thousands of engineers.

Unfortunately it has not quite worked out as planned. As reported by the Albany NY Times Union: “GlobalFoundries delays fab plans, construction of facility in Abu Dhabi put on hold; Malta expansion in doubt” due to the “uncertain global economic outlook”? As reported on SemiWiki last week by Bill Jewell of Semiconductor Intelligence: Semiconductor market to grow 3% in 2011, 9% in 2012. I agree with Bill, 2012 will be a significant semiconductor growth year, so I’m not buying the uncertain global semiconductor economic outlook excuse. To me, this is a case of poorly set expectations and as a result, a failure to implement.

GlobalFoundries partner and number one customer AMD recently blamed a revenue shortfall on “continued 32nm manufacturing issues” which resulted in shortages of the Llano APU. AMD Q3 revenue growth was closer to 5% versus the forecasted 10% with lower margins than expected. Other AMD products have been delayed, some products have been moved to TSMC. The blame again falls on GFI’s inability to deliver.

This is an interesting dynamic since AMD and GlobalFoundries share board members and equity. The 32nm manufacturing facilities in question belonged to AMD (Dresden) as do the employees that run them, so they are in effect pointing the blame finger at themselves. But since AMD is a publicly traded company and GlobalFoundries is private, rhetoric to boost AMD stock value is a net gain.

Meanwhile GlobalFoundries and AMD are both doing the executive shuffle with new CEOs and other key infrastructure members. Several of the GlobalFoundries guys now work for the foundry group at Intel, which is interesting. Comments on LikedIn thus far are running negative:

“Has the “Energy” money tap been turned off for the Semiconductor industry? GloFo is asking for more money? “A proposed second fab in Malta is also off the table, the company says, unless New York State officials approve even more financial assistance.” Maybe it’s just politics, either way, interesting development (or lack thereof).”David Bethke

“This is too bad but not completely unexpected. Considering the current world market it is a huge task to try to open several phases of the NY fab and a completely new one in an area of the world where there is little semiconductor manufacturing experience.”Stephen Griffing

You forgot to add: “due to flooding in Thailand”, “due to inept executive management”, and “due to unreasonable shareholder expectations, reducing corporate reinvestment and key employee acquisition and retention.”Andy Turudic

I will dig deeper in the coming weeks. Let me know what you think of GFI’s prospects moving forward and I will keep you posted on what I find out.

Note: You must be logged in to read/write comments.

Learning about 3D IC Design and Test, IEEE Workshop on Friday, December 9th in Newport Beach, CA

The IEEE has an Orange Country Chapter of the Components, Packaging and Manufacturing Technology Society who are organizing an all-day workshop, 3D Integrated Circuits: Technologies Enabling the Revolution. This looks to be an informative day with real-world examples in both design and test being presented by over a dozen experts. Registration details are here.

Continue reading “Learning about 3D IC Design and Test, IEEE Workshop on Friday, December 9th in Newport Beach, CA”

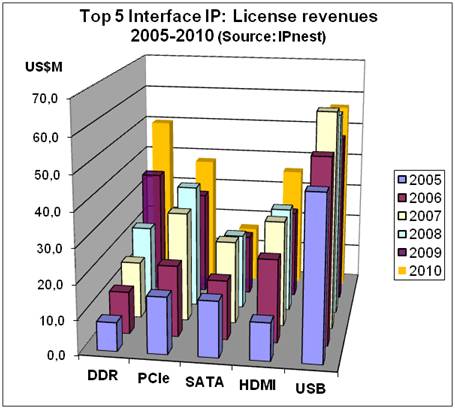

A tribute to Research on Interface IP Market

Denali acquisition by Cadence in May 2010, ChipIdea, Virage Logic, and nSys acquisitions by Synopsys in 2009, 2010 and 2011 (resp.) shows that IP market is consolidating… but new IP vendors are still emerging! So we need to know on which product the Interface IP market leader will tend to a dominant position, which new products will be added to their port-folio, what could be the new strategy from the well known EDA challenger in Interface IP and Verification IP, and get information about the new comers, or IP vendors start supporting emerging protocols…

The use of High Speed Serial Interconnect instead of parallel interface is becoming the preferred solution for new products developed across various segments. In this survey, we study the Interface IP market, looking at all the existing protocols: PCIe, USB (HS & SuperSpeed), Serial RapidIO, Infiniband, Hyper Transport, SATA, Fibre Channel, HDMI, Ethernet, XAUI, Display Port, MIPI and DDRn, and extracting the most promising in term of long term growth. To understand the market, we first analyze for every selected IP segment, the market share, growth rate and positioning of the different vendors, for 2005-2010. Then, we propose a market forecast on the period 2011-2015.

We can see on the above picture the negative impact of the Q4 2008-Q1/Q2/Q3 2009 recession on the growth rate for every segment – except DDRn Memory Controller. Even if in 2010, the market has recovered, we should come back to 20-30% like growth rate only in 2011. In the survey, we have made an analysis, by protocol standard (USB, USB 3.0, PCIe, SATA, DDRn, HDMI) of the market evolution from 2005 to 2010, detailing the revenue by vendors, like we can see on this example for PCIe IP:

What will happen in the future depends, as always, of the health of the global economy. Assuming no catastrophic event, 2010/2011 growth should continue in 2012, and the interface IP market should reach a $350M level, or be 58% larger than in 2009 (a 17% CAGR during these 3 years). The reasons for growth are well known (at least for those who read Semiwiki frequently!): the massive move from parallel I/Os to high speed serial, the ever increasing need for more bandwidth, not only in Networking, but also in PC, PC peripheral, Wireless and Consumer Electronic segments – just because we (the end user) exchange more data through Emails, Social Media, watch movies or listen music on various, and new, electronic systems. Also because these protocols standards are not falling in commoditization (which badly impact the price you sell Interface IP), as the various organizations (SATA, USB, PCIe, DDRn to name the most important) are releasing new protocol version (PCIe gen-3, USB 3.0, SATA 6G, DDR4) which help to keep high selling price for the IP. For the mature protocols, the chip makers expects the IP vendors to port the PHY (physical part, technology dependant) on the latest technology node (40 or 28 nm), which again help to keep price in the high range (half million dollar or so). Thus the market growth will continue, at least for the next three to four years.

On the long term, the Interface IP revenue is expected to double on 2015/2009 periods, going from $220M in 2009 up to $450M in 2015, growing at a 12.4% CAGR. In the same period, the Semiconductor market, like any mature market, will tend to rationalize his sourcing strategy. Instead of having to select a different IP vendor for every different interface standard, or even for the PHY and the Controller for a given standard, an IDM or Fabless will prefer the one stop shop concept, at least for a family of IP like the wired Interface IP. This one stop shop concept will be extended to Verification IP, to be offered by traditional IP vendors.

As of today, there is one market leader: Synopsys. Instead of inventing a standard, or to invest upfront, the company has grown through successive acquisition of small, focused and successful IP vendors. This is true with USB, PCIe, DDR and HDMI! And they are now number one and ultra dominant in USB, dominant in PCIe, number one in SATA, number one in DDRn, and starting in HDMI and MIPI. Their key strength is their worldwide direct sales network, able to reach every design team in the world (thanks to their logic synthesis tool), and their ability to provide each of the Top 5 standard based IP. Initially, the one stop shop concept was developed by “generic IP” vendors, like CAST, to sell commodity functions. Since 2009, we can see Synopsys as the one stop shop company selling highly specific, complexes Interface IP like USB 3.0, PCIe Gen-3, SATA II and III, HDMI and DDR3. Thus we expect Synopsys to lead this market in 2015, like they did it in 2009, where they enjoyed $83M or 38% market share on Interface IP or 2010 with $100+ million and more than 40% market share.

Is there is room for another IP vendor competing with Synopsys?We think there is still room for another IP vendor to compete on the Interface IP segment (the market does not like to have such a reduce choice). In the past, Mentor Graphics has tried to build an IP port-folio, to finally exit the market. Nevertheless, two EDA vendors (Cadence and Mentor Graphics) have a key strength that you absolutely need to be successful on the IP market: a worldwide sales force able to have access to almost every design team in the world. They also get enough cash to grow by acquisition (like did Synopsys, in fact)! Such a new comer should remember that he will have to provide an integrated solution. This means he will have to manage both the Digital (Controller) part of the IP and the Analog (PHY) and probably also the software drivers. Talking about Cadence, if they want to be present on this IP market which represent already several $100M and will grow at a 12% CAGR from 2010 to 2015; we would expect a next step after Denali acquisition! It would be to acquire one (or several) IP vendor strong in Interface IP in general (Denali is strong in DDRn but very weak everywhere else) and be able to propose a wide PHY IP port-folio. They could develop a PHY product line from scratch, but this is far to be the easiest way.

Finally, what could be the challenges for the wired interface IP market itself?We have seen that the decline in ASSP/ASIC design starts, which is real, is more than compensated by two distinct effects. The SoC proportion of ASIC/ASSP is enough growing and generating new needs for Memory Interface and High Speed Serial Interconnect to compensate this decline. The second effect is the high demand for Data bandwidth in the PC and Consumer Electronics markets, which can only be satisfied by moving from the old, parallel based, interconnect link to the High Speed Serial Interconnect. The availability of serial protocols, like USB, PCIe, HDMI, MIPI and SATA, allows the pervasion into multiple applications, in various market segments, so the number of design starts including these IP is growing. Finally, the emergence of ThunderBolt, promoted by Intel, could perturb the market, probably not now but in the mean term. If this standard is really used, what will happen to the PHY IP vendors for protocols like USB 3.0, HDMI or eSATA? As a matter of fact, the decision from Intel to delay up to Q2 2012 the integration of USB 3.0 into the PC chip set was not good news for the USB 3.0 IP vendors.

Another challenge could be the relationship between the IP vendors and the Silicon foundries. In fact, the interface IP, and more specifically the PHY IP, has become a function present in almost every design, which can be seen by the foundries as a hook to keep a customer locked with their technology. The FPGA vendors were the first to understand it, and they license IP not to generate IP sales, but to lock their customer to their technology. It will be interesting to monitor what will be the strategy of the Silicon foundries in respect with the (PHY) interface IP vendors in the future.

Eric Esteve from IPNEST – Table of Content for “Interface IP Survey 2005-2010 – Forecast 2011-2015” available here

Happy 40th birthday microprocessor

Intel has been making a little bit of a PR fuss about the 40th anniversary of the microprocessor. And they are entitled to. The Intel 4004 was the first customer-programmable chip. Of course if you look at it’s capabilities today they are laughably minimal, and even looking at the chip, a 16-pin DIP (dual-in-line-package for anyone under about 40, pins down both sides of a plastic or ceramic package). Here’s a picture of what it looked like . Microprocessor? Not on a thousand pin BGA?

Federico Fagini and Ted Hoff designed it and there are some great quotes from them as the first silicon fails but the second turn works. Most people in tech know the story that a company in Japan, Busicom, contracted Intel to build a calculator chip but they worked out that the best way to do that was to design a programmable device and then program it to be a calculator. But like so many design projects it was late. Fagini got drafted into the project his first day at Intel when an engineer from Busicom showed up to check how the project was going:

Masatoshi Shima: You bad! You bad!

Faggin: I just arrived here! I just was hired yesterday!

Masatoshi Shima: You late!

This was ages before personal computers. As Ted Hoff said:

At that time, it didn’t really make sense to talk about personal computers.

Three years and four chip generations later we arrived at the 8088 which was the heart of the original PC. One or two floppy disks, back when they really were floppy. Or even none, you could use cassettte tape if you couldn’t afford those expensive disks.

But even Gordon Moore was somewhat unconvinced:

I was Chief Executive at Intel I remember one of our young engineers coming in and describing how you could build a little computer for the home. I said gee that‘s fine. What would you use it for?‘ And the only application he could think of was housewives putting their recipes on it. I didn‘t think that was going to be a very powerful application.

And over at Digital, then chairman Ken Olsen made his famous remark in 1977:

I see no reason for any individual to have a computer in his home.

That has to be up there with Watson’s quote at IBM that he only saw a market for 5 computers. ARM ships billions every year. A million PCs, roughly, ship every day.

But, as I’ve said repeatedly, power is the big problem. Here’s Justin Ratner, Intel’s CTO:

Today, a petaFLOPS computer is burning somewhere between five and seven megawatts. So if we just scaled it up by 1000x it would be in the gigawatt range and I‘d have to buy everyone a nuclear reactor to run that machine; maybe a couple of nuclear reactors.

But he’s optimistic:

The sheer number of advances in the next 40 years will equal or surpass all of the innovative activity that has taken place over the last 10,000 years of human history.

At this point, it‘s fair to ask, what lies ahead? What lies beyond multi-core and many- core computing? And the answer… is called extreme-scale computing. This is multi- core and many-core computing at the extremes. Our 10 year goal here is to achieve nothing modest: a 300x improvement in energy efficiency for computing at the extremes.

As Dan Hutcheson of VLSI Research said:

The roots of all things smart, personal and mobile is the Intel 4004.

And I think he’s right.