Over the years many attempts have been made to increase the level of automation in analog design. Most of these have not been especially successful. Probably part of the reason was inadequate technology but also there is an attitude that “real” analog designers design polygons on the bare silicon. I think two things have changed. Firstly, the technology for analog design, balancing automation with manual control, has improved a lot. And secondly, as more and more is integrated onto big SoCs in leading-edge processes, analog design has had to make a huge increase in productivity to keep up and it is no longer possible to ignore automation.

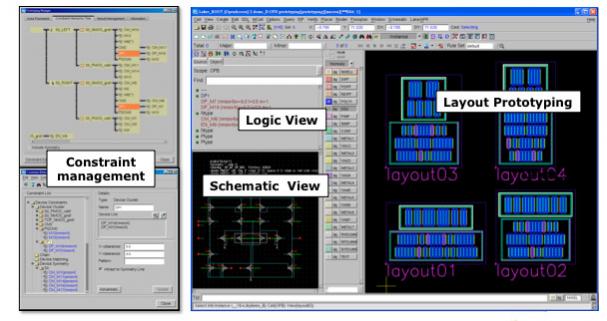

Laker Analog Prototyping is a new generation of technology. It brings together in one integrated interactive environment:

- layout prototyping

- constraint management

- logic view

- schematic view

- integrated placer

- integrated router

The heart of analog automation is constraint management. There are much more complex interactions between analog circuits than digital and so the designer has to be able to quickly and easily specify these. Even a single transistor can be laid out in many different ways depending on performance, the space available, other devices and so on. For accuracy, many devices and signals have to be symmetric. The analog designer may also have a very good idea of which devices should be clustered together.

However, specifying all the constraints can be time-consuming and tiresome, so in addition to allowing the designer to specify constraints manually, Laker can extract constraints automatically since it recognizes many circuit types and has sensible default constraints to use, automatically matching device and signal pairs for example.

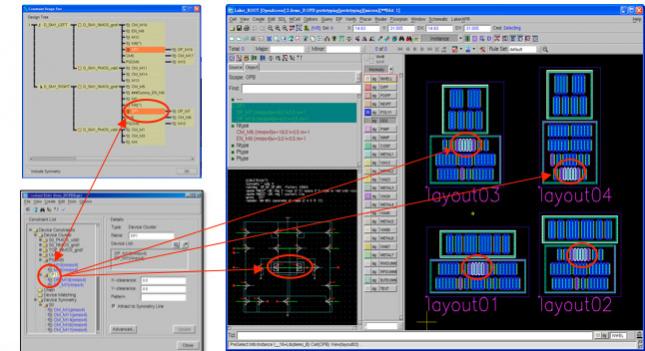

Another important capability is the ability to cross probe in the integrated environment, picking up the same device in the constraint view, the hierarchy tree, schematic and layout.

Under the hood, of course, is a placer that can generate multiple candidate placements based on the contraints, aspect ratio, wire length and so on. The result manager makes it easy to see which trial layouts have good wire length, area and so forth. Good candidates can be saved for further analysis. Routing is also integrated and allows routing estimation to be used during placement.

Of course the goal of all this automation is two fold: better layouts and a faster, more predictable schedule. Doing everything by hand the old way is no longer a good route to either of those goals. The analog prototyping is build directly in the Laker schematic-driven layout environment so the user still has full manual control and can decide the level of automation that is appropriate.

TSMC vs Intel Foundry vs Samsung Foundry 2026