In an era where product differentiation increasingly depends on performance, power efficiency, and form factor, Application-Specific Integrated Circuits (ASICs) have become the ultimate competitive weapon for innovative companies. Unlike off-the-shelf processors, FPGAs, or even ASSPs, a full- or semi-custom ASIC is engineered from the ground up (or from proven building blocks) for one specific application. The result: dramatically lower unit cost at volume, smaller size, lower power consumption, higher performance, better supply-chain control, and strong IP protection.

The whitepaper published by imec’s IC-Link division makes a compelling case that ASICs are no longer reserved for tech giants. Advances in design tools, IP reuse, multi-project wafer (MPW) shuttles, and mature foundry ecosystems have made custom silicon accessible even to startups and mid-sized companies.

Key advantages at a glance

- Cost efficiency at scale: While NRE can reach tens of millions for leading-edge nodes (e.g., ~$40 M for a 7 nm high-performance design), the per-die cost drops sharply. The paper shows a realistic 7 nm example where the ASIC unit price lands at $50–60 versus $90–100 for comparable commercial CPUs, delivering ROI of 1.26× over a nine-year lifecycle at 250 k units/year.

- Miniaturization & integration: Combining multiple functions into one die (or advanced SiP) shrinks the solution dramatically—critical for wearables, implants, and IoT devices.

- Ultra-low power: Shorter interconnects, optimized power management, and removal of unused blocks routinely cut power by 5–10× compared with FPGA or discrete implementations.

- Performance: Tailored datapaths, dedicated accelerators, and shorter signal paths deliver the highest throughput at the lowest energy.

- Supply-chain resilience & IP protection: A single chip replaces dozens of components from multiple vendors, eliminating obsolescence risks highlighted during the COVID shortage era. Reverse-engineering a modern ASIC is also prohibitively expensive.

Real-world proof points

- Capri-Medical’s injectable migraine implant: reduced from a 3-hour surgery to a 20-minute outpatient procedure thanks to an ultra-small, multi-function ASIC.

- Wiyo’s battery-less Wi-Fi-powered smart tags: only an ASIC could meet the microwatt power budget while harvesting energy from ambient 2.4 GHz signals.

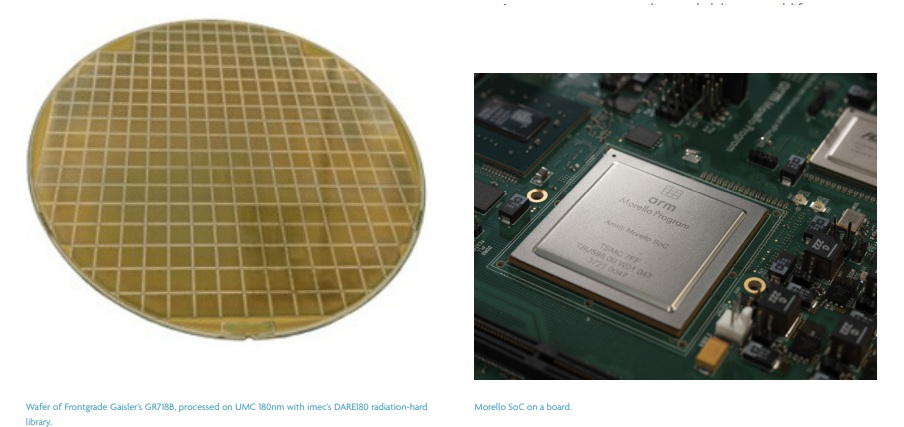

- Frontgrade Gaisler’s radiation-hardened space processors and Arm’s Morello secure SoC: both rely on custom silicon to satisfy extreme reliability and performance requirements that no commercial part can match.

The ASIC journey demystified The whitepaper walks readers through every phase: from initial feasibility and system architecture, through detailed ASIC specification, RTL-to-GDSII design (digital) and full-custom layout (analog), co-design of chip and advanced package, mask making, assembly, test development, qualification, and finally volume production. IC-Link emphasizes early package co-design and the importance of design-for-test (DFT) to avoid costly test escapes.

Why partner with IC-Link? As imec’s dedicated ASIC service arm, IC-Link offers two flexible business models:

- Full Turnkey (low risk): one single point of contact from specification to delivered tested parts.

- Customer-Owned Tooling (lowest cost): customers select only the services they need while retaining full control.

With direct access to TSMC, GlobalFoundries, UMC, and specialty processes (including imec’s own radiation-hard libraries), plus decades of packaging and test expertise, IC-Link has supported everything from 180 nm medical implants to 7 nm memory PHYs and complex 18-layer security SoCs.

Bottom Line: For any company facing size, power, cost, or supply-chain constraints—and targeting volume production—an ASIC is no longer a “nice-to-have.” It is rapidly becoming a strategic necessity. The imec IC-Link whitepaper convincingly shows that the barriers to entry have fallen: the expertise, tools, and manufacturing capacity now exist to bring custom silicon within reach of virtually any serious innovator. The question is no longer “Can we afford an ASIC?” but “Can we afford not to have one?”

Also Read:

Revitalizing Semiconductor StartUps

Podcast EP320: The Emerging Field of Quantum Technology and the Upcoming Q2B Event with Peter Olcott

Live Webinar: Considerations When Architecting Your Next SoC: NoC with Arteris and Aion Silicon

Share this post via:

TSMC vs Intel Foundry vs Samsung Foundry 2026