There’s a dirty secret problem about EUV that people don’t seem to to be talking about. There’s no pellicle on a EUV mask. OK, probably you have no idea what that means, a lot of jargon words, nor why it would be important, but it seems to me it could be the killer problem for EUV.

In refractive masks, you print a pattern on a plate of quartz. Then you cover it with another layer known as the pellicle (I speak French and that is the name for film in the pre-digital era camera, but it seems to mean a thin skin of any type). It’s basically a cover so nothing can ever get to the mask that wasn’t already there. So any contamination that gets on the reticle is actually on the pellicle. During exposure in the stepper, 193nm light is transmitted through the mask onto the photoresist on the wafer. But the light is focused in a way that the mask itself is the important part of the beam and contamination on the pellicle (unless totally gross, obviously) doesn’t affect anything, so the defect is de-focused. Like a speck of dust on the lens of your iPhone, it just won’t show up. In lithographic terms, it doesn’t print.

In refractive masks, you print a pattern on a plate of quartz. Then you cover it with another layer known as the pellicle (I speak French and that is the name for film in the pre-digital era camera, but it seems to mean a thin skin of any type). It’s basically a cover so nothing can ever get to the mask that wasn’t already there. So any contamination that gets on the reticle is actually on the pellicle. During exposure in the stepper, 193nm light is transmitted through the mask onto the photoresist on the wafer. But the light is focused in a way that the mask itself is the important part of the beam and contamination on the pellicle (unless totally gross, obviously) doesn’t affect anything, so the defect is de-focused. Like a speck of dust on the lens of your iPhone, it just won’t show up. In lithographic terms, it doesn’t print.

EUV masks are reflective and can’t have a pellicle, because the light would not go through it (EUV is absorbed by everything which is why EUV systems have to be in a vacuum, and why the mirrors are so complicated, a regular mirror would absorb everything). But that means that any contamination on the mask is in the focal plane that we care about and will make it onto the wafer. So the standards for cleanliness inside an EUV stepper are insane. After all, a single particle on a mask will be stepped across hundreds of wafers. If it is in an early layer, then dozens of process steps will take place and eventually…zero yield. And by the time this is realized it is weeks later. In practice, no particles can be present at the time of exposure. That’s a high bar. Particles on the pellicle don’t really matter, which is what we have got used to. EUV is different.

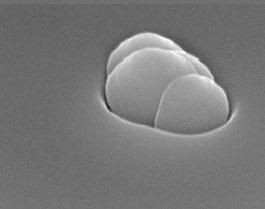

So keeping the mask clean is a major issue. There is lots of work going on on how to keep EUV masks clean but the standards are essentially perfection. EUV masks are 4X the size on the wafer so at 20nm the problem is particles around 50-80nm (big enough to cut a line or break contact). But that is still tiny. Further, masks cannot be cleaned all the time, they are in the stepper most of the time. And there is no way, today at least, to detect, while they are in use, that a problem has arisen.

So keeping the mask clean is a major issue. There is lots of work going on on how to keep EUV masks clean but the standards are essentially perfection. EUV masks are 4X the size on the wafer so at 20nm the problem is particles around 50-80nm (big enough to cut a line or break contact). But that is still tiny. Further, masks cannot be cleaned all the time, they are in the stepper most of the time. And there is no way, today at least, to detect, while they are in use, that a problem has arisen.

This is a huge change. At previous process nodes contamination could occur on the wafer (knocking out a die) or on the pellicle (having no effect). Now contamination on the mask affects not just a single die but all die until it is cleaned.

Share this post via:

TSMC vs Intel Foundry vs Samsung Foundry 2026